Characteristics |

||||

|

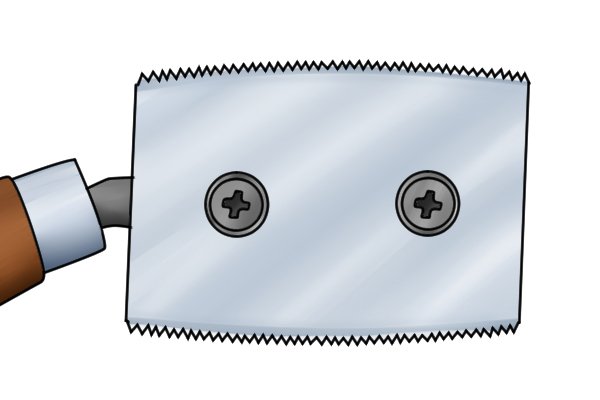

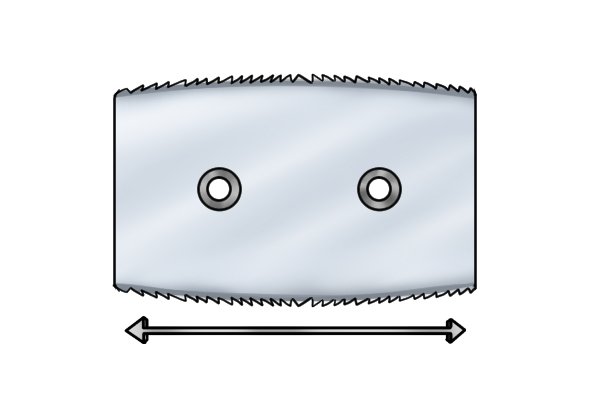

BladeLike a traditional veneer saw blade, a double-sided one is also curved. The blade length will vary between brands but most blades are between 70 – 100mm (2.7-3.9″) in length. |

|||

|

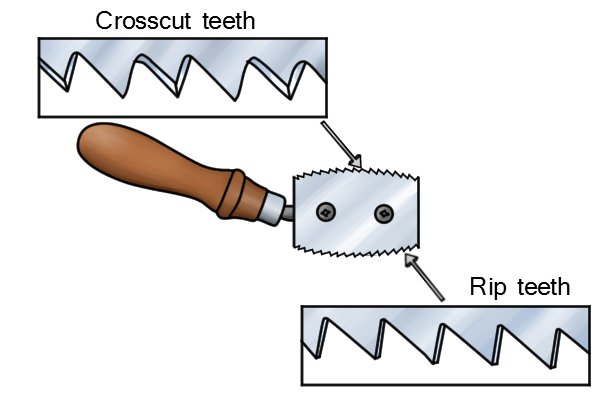

Crosscut and rip teethOn some models, one set of teeth will be specially designed for cutting across the grain of the wood (crosscut teeth), and the other set will be designed for cutting with or along the grain (rip teeth). |

|||

|

Teeth Per Inch (TPI)A double-sided veneer saw will usually have 11 or 12 teeth per inch. Compared to a traditional veneer saw, which has a higher TPI, these saws may not produce as neat a finish. However, because the teeth are small, and the gullets shallow, you should be able to produce a relatively neat cut. |

|||

|

Cutting strokeSome models have one set of teeth which cut on the pull stroke, and another that cut on the push. For more information visit: Push stroke saws vs. pull stroke saws. |

|||

|

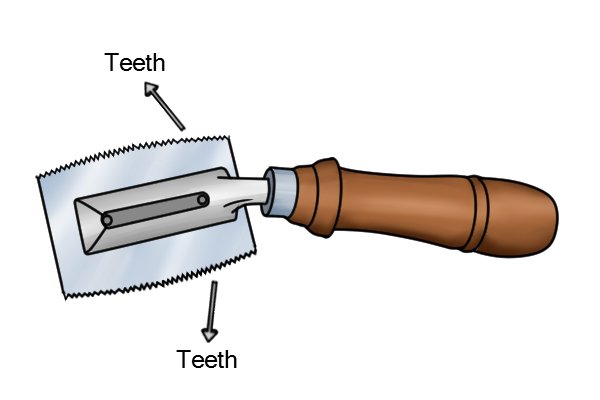

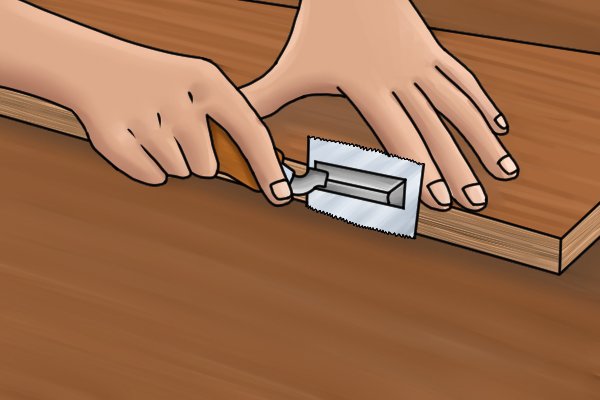

HandleThe handle on a double-sided veneer saw is angled upwards away from the blade, to allow for flush-cutting. Flush-cutting is cutting away excess material to create a level and even surface. |

|||

|

Once you have cut your veneer sheet to size and attached it to a wooden board, you can use the double-sided veneer saw to cut away any excess material by placing it flat on the board’s surface. The handle’s position above the blade allows you to do this. | |||