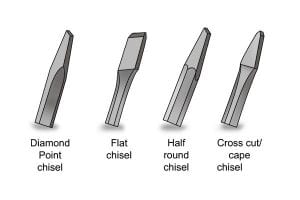

What are the different types of cold chisel tip?

Cold chisels are chisels normally designed to be used on unheated metals which are softer than themselves, but you may find them being used when working with stone, brick and concrete as well.

Metals they can be used on include wrought iron, copper, brass and aluminium. Low carbon steels are often soft as well.

They come in a variety of different shapes. The flat chisel, cross-cut or cape chisel, the half-round and the diamond point chisels are the ones which you are most likely to come across.

Flat Chisels

The flat chisel is the basic cold chisel, used in the cutting of a variety of metals. The cutting edges of some flat chisels may be somewhat rounded because otherwise, the corners may start to gouge the surface the chisel is being used on. When using a flat chisel to cut through sheet metal, tilting the chisel to the side allows the user to move forward with the chisel in a straight line.

If you wish to cut a shape out of metal, this can be accomplished by drilling holes to outline the shape. This reduces the amount of metal you will need to remove with the cold chisel. However, the cold chisel may bend and deform the metal unless the shape is near the edge. Flat chisels can also be used to break off things such as rivet heads and nuts and break metal rods.

Crosscut or Cape Chisels

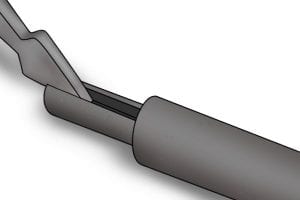

The crosscut (or cape) chisel is designed for those who want to get into those tight areas. The design of the tool is such that the handle is thinner than the cutting edge, which narrows on two sides until it reaches a point. This chisel is designed not to get stuck where a flat chisel might.

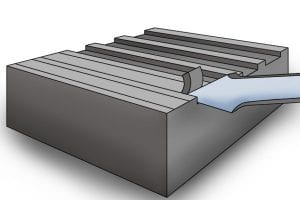

The crosscut chisel can also be used in conjunction with a flat chisel on larger surfaces. Firstly, the crosscut chisel is used to make a series of grooves. Then a flat chisel can be used to remove what is left.

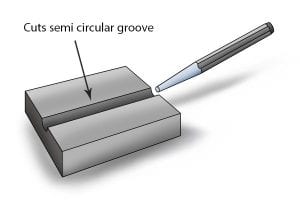

Half-Round Chisel

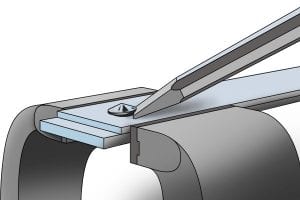

The half-round chisel is a type of chisel which has a rounded shape, although the top of the tool is actually flat. It is designed to create grooves/channels with rounded bottoms. Such grooves may be found in bearings, acting as “oil ways”. Sometimes this chisel may be called a “round nose chisel”.

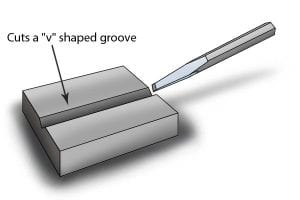

Diamond Point Chisels

The diamond point chisel has a diamond shaped tip and is used to create grooves with a “V” shape, something which may be desirable in many instances, including carving. It is also used in corners and in the moving of incorrect marks left by a centre punch. Some diamond point chisels may be better suited to use on brickwork.

Utility Chisels

Some cold chisels may also be found under the name “utility chisel”. Some of these may simply be longer versions of the tool with a wider cutting edge.

Longer cold chisels may be used when trying to get into hard-to-reach areas. It is possible to purchase cold chisels made from a grade of steel which simply is not suitable for cutting through all metal.