What are the different types of aviation snips?

Aviation snips are designed for cutting a variety of tough materials, and in different directions. Because of this, they come in a few different designs, so you should be able to find a pair of snips to suit the job you need them for.

What are the most common types of aviation snips?

The three main designs you will come across are: straight, left, and right cut snips, but there are other variations in their design. They are usually between 230mm and 300mm (9 inches and 12 inches) long. However, you’ll also find long cut versions which can be up to 325mm (12.8 inches), and also compact aviation snips which can be as small as 180mm (7 inches).

When talking about aviation snips, the direction specified (e.g. left) refers to the direction in which the tool is designed to cut, not the hand they should be held in. The waste material will exit on the specified side, and the rest of the material will be kept straight. Aviation snips can be used in both hands, although they are usually designed to be used in the right hand.

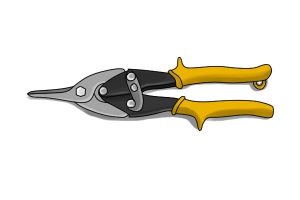

Straight Cut Aviation Snips

These snips are designed to make cuts which are straight or slightly curved, towards either the left or the right.Straight cut aviation snips usually have a yellow colour code.

They work well at making cuts the length of the blade, so they are best suited to cutting notches on the edge of sheets. The length of the blades is the tool’s ‘cut length’ and there will be slight variations of blade length between models, usually between about 30 and 45mm (1.25 inch-1.75 inch).

These snips are mostly used for straight cuts where both sides of the material need to be kept level. They work well with long cuts in softer metals, or other lighter materials, but are unsuitable for long cuts through tough metal sheets.

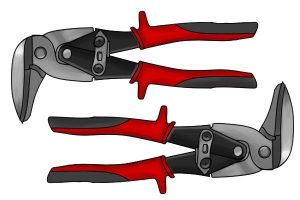

Left Cut Aviation Snips

Left cut snips are most suited to cutting straight, and for curves towards the user’s left. They should be able to cut tighter left curves than the straight cut snips, because of the angle of the blades. These snips are designed for the waste material to be on the left side as it cuts, this means that it should curl the left piece of material up so can be moved out of the way. These snips will usually have a red colour code.

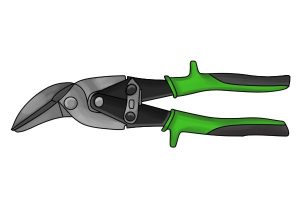

Right Cut Aviation Snips

Right snips are designed to cut straight and for tight arches towards the right. So, for these snips the waste material will be coming off the right side, and curling out of the way. Right cut snips are usually colour coded green.

Long Cut Aviation Snips

Long cut snips have longer blades than the standard straight snips. They are effective at making long straight cuts and large diameter curves, either left or right. Similar to straight cut snips, they are particularly good for notch cutting on the edge of materials.

Bulldog Cut Aviation Snips

These snips have much shorter blades which make them ideal for cutting out notches, or working on trim. They’re called bulldog cut aviation snips because they have a short ‘nose’, just like a bulldog.

The shorter blade has slightly more leverage so the tool can cut through seams and other thicker materials. They will cut straight or in short, shallow curves.

Utility Cut Aviation Snips

These snips are usually designed for cutting slightly lighter materials than most other aviation snips, due to their less tough and longer jaw. They are able to make straight cuts and slight curves.

They are named utility cut because they designed for more general use and will usually be more of a lightweight tool. They are suitable for cutting thick cardboard, vinyl, and other similar materials around the home.

Offset Aviation Snips

If snips are described as being ‘offset’, they are suited for making longer cuts. They will offset the waste material underneath the workpiece, pushing it down as the cut is made. This is a safer way to cut longer pieces as the waste will be moved down, and away from the user’s hand.These snips work well for longer cuts through fairly rigid sheet steel, because the waste does not need to curl up, as with other left and right aviation snips.

The offset jaws mean the user’s hand is positioned above the material when cutting. These snips will generally be available in straight, right and left versions, with the same colour coding as other left and right snips.

Upright or Right Angle Aviation Snips

The blades of right angle aviation snips are set at a right angle to the handles, so that they can be used for making cuts overhead, or in other awkward places, which would be difficult to reach with other snips.

The angling of the blades means that they do not have as much leverage as other aviation snips, so they may only be suitable for lighter gauge metal, unless they are longer. These will be available in right and left cut styles, and will usually have the standard red and green colour coded.