What are aviation snips made of? |

||||

| Shop for Tinsnips and Aviation Snips | ||||

|

Aviation snips need to be strong and durable as they are designed for cutting tough materials. They are hand tools which are meant to be carried around, so they also need to be lightweight. | |||

Steel |

||||

|

The blades should be tough and so most are made from hardened steel. The harder the steel is, the tougher the material it will be able to cut through. Aviation snips cannot cut hardened steel as that would match the strength of the blades and could cause damage to the tool. | |||

|

The type of steel that aviation snips are made from is hardened, for extra strength. Usually this is chrome molybdenum steel or chrome vanadium steel.The addition of chromium and other elements will improve many of steel’s properties, and make the tool more effective while keeping it lightweight. However, there are different grades of these steels so the reputation of the brand and the cost of the tool are likely to reflect the quality of the steel it’s made from. | |||

|

Chrome molybdenum steelThe addition of the elements chromium and molybdenum to steel improves the hardenability of the alloy, they also increase its strength when at high temperatures. The steel will also gain extra corrosion, impact and wear resistance. |

|||

|

Chrome vanadium steelAdding chromium and vanadium to steel also adds strength, toughness and corrosion resistance. Vanadium also increases steel’s ability to work in high temperatures and makes it more resistant to corrosion. Generally, vanadium is stronger than molybdenum, but more brittle. |

|||

|

||||

|

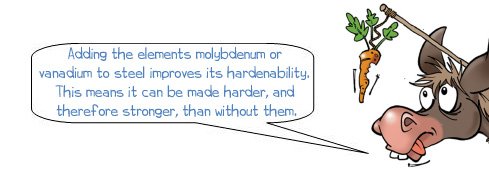

Vanadium or molybdenum steel?There is not a straightforward answer to this because it depends on the way the steel has been manufactured, and the amount of alloying elements that have added to it. For aviation snips, their strength is paramount, however they also need to have some flexibility so they don’t snap with the force that is needed to cut tough materials. |

|||

|

You will usually find that chrome molybdenum aviation snips can cut tougher and thicker materials than chrome vanadium, but chrome vanadium snips are often cheaper. | |||

Titanium nitride coating |

||||

|

The blades on aviation snips not only need to be sharp but also durable, so they can keep a clean cut while working with tough materials. Some snips have blades which have been specially coated with titanium nitride, which is recognisable by its yellowish colour. | |||

|

Titanium nitride is a non-metallic material which is exceptionally hard. A very thin layer of this over the steel improves its strength, makes it more corrosion resistant and keeps the blade edges sharp for longer. However, titanium nitride coatings can be expensive, so are likely to make the tool cost more. | |||

Rubber and plastic |

||||

|

Aviation snips are steel constructs, however, their handles are coated in a softer material such as plastic or rubber. This coating is shaped on the handles so as to make the tool fairly comfortable to use and therefore reduce user fatigue. Some handles also have grips, which stop the user’s hand from slipping towards the blades. | |||

|

Rubber and plastic comfort the hand so the tool can be used for longer. The main difference between rubber and plastic is that rubber is more heat resistant, but plastic will have a slightly higher impact resistance. | |||

|

Rubber or plastic?You may want to consider the environment they will be used in, to pick the appropriate handles. If the snips will be used at increased temperatures you may want to consider rubber handles, while plastic handles may be more suitable if the snips are likely to experience frequent knocks. |

|||