What is an impact socket?

Impact sockets are designed for use with powered impact wrenches or ‘drivers’, as they are sometimes called. Impact wrenches can be powered pneumatically (by compressed air), electrically, or hydraulically (oil).

The combination of an impact wrench and impact socket can deliver greater torque to the head of a fastener than can be achieved with a manual wrench.

Impact wrenches are often used by mechanics in garages to remove seized nuts and bolts from vehicles, and by racing teams to quickly apply large torque loads to wheel nuts to hold them securely.

An impact wrench stores kinetic energy in a rotating hammer that is forced (impacted) against an anvil which then delivers force to the driver. As this force is delivered on impact in a short burst instead of continually, the torque is multiplied.

How are impact sockets different from other sockets?

Impact sockets have to be designed to cope with the vibration caused by the impact of the hammer on the anvil, inside the impact wrench, as well as the much greater levels of torque this can generate.

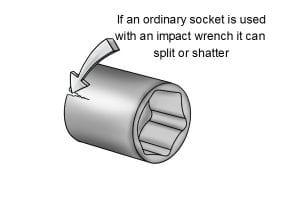

If an ordinary socket was used with an impact wrench, it would be likely to shatter.

Impact sockets are a different colour to other sockets, due to the black oxide coating (also called ‘industrial surface finish’), that is applied to them. Black oxide is used as a surface finish on impact sockets to protect against corrosion, as chrome plating would chip and flake off, due to the vibration caused by a powered impact driver.

The black colouring also helps to distinguish impact sockets from other sockets, making it easy to see which sockets can be used with a powered impact wrench.

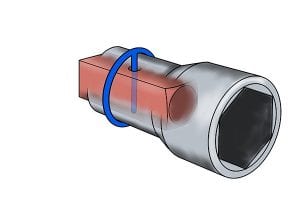

The drive socket end of larger impact sockets has a grooved ring around the outside. This enables a locking pin and retaining ring to be used.

Locking pins fit through the side hole of the impact socket and the drive square of the impact wrench.

The locking pin helps to prevent the socket coming off the end of the impact wrench drive square due to the vibration during operation. Retaining rings sit in the groove around the outside of socket and hold the locking pin in place.

Newer designs incorporate the locking pin and retaining ring in one piece, which further improves the securing of the locking pin.

Some newer designs also feature a resin tip to the locking pin, which is designed to be crushed as the socket or drive square becomes worn and indicates that one or both need replacing.

How are impact sockets made to withstand vibration and high torque loads?

Unlike regular sockets, which are predominantly made of chrome vanadium steel, quality impact sockets are made of chrome molybdenum. This is because chrome vanadium, whilst strong, is also relatively brittle.

This brittleness means that if a chrome vanadium socket was subjected to the vibration and torque forces generated by an impact wrench, it could shatter. Chrome molybdenum on the other hand, is a more ductile metal that will deform rather than shatter.

This is what makes impact sockets so much more effective when completing tasks such as removing wheel or lug nuts using an pneumatic impact wrench.

Wonkee Donkee Tip: “Beware, while cheaper, poor quality impact sockets may have a black oxide finish, some are still made of chrome vanadium and so are at risk of shattering when used with an impact wrench.”

What are the advantages and disadvantages of impact sockets compared with manual sockets?

Advantages

Can be used with both impact and powered turning tools as well as manual ones

Less chance of injury from sockets shattering

Can be used to apply greater torque to a fastener

Disadvantages

More expensive than manual sockets

Only available with a black oxide coating

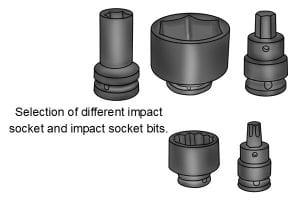

What type of impact sockets are available?

You can get impact sockets with all the same socket head types and drivers as hex sockets and in-hex sockets.

Impact socket bits are usually a one-piece construction unlike other socket bits. This is due to both the bit and socket body having to be made of the same material that will withstand vibration and high torque loads.

However, some larger industrial socket bits are made as two-piece as its more cost effective at this size to replace the bit rather than the whole socket bit.

There are not just a range of impact sockets but also hundreds of different types of socket that are available.