Socket Maintenance and Care

Taking a bit of time to correctly store and maintain your sockets should give you trouble-free use for many years to come.

Cleaning

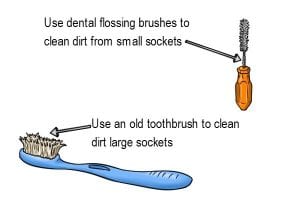

When you have finished using your sockets, make sure they are clean before putting them away. Any muck or dirt should be brushed off, and don’t forget to brush out the inside of the socket head and drive socket as well as the outside of the socket.

Muck and dirt can scratch away at the protective coating applied to the socket and trap moisture which could result in corrosion. Large sockets can be cleaned with an old toothbrush, whilst smaller ones are best cleaned with dental flossing brushes.

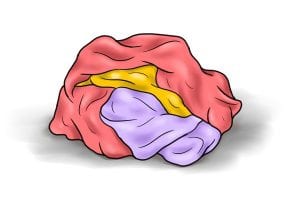

It is most important that sockets don’t have water left on them as this could cause rust to form. If they are wet, they should be dried with a cloth before being sprayed with a water displacing oil.

Storing Sockets

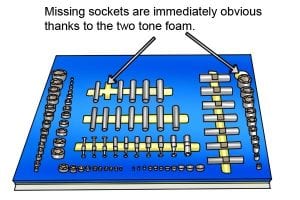

Sockets should be kept stored in a storage system such as a socket case, on socket rails or foam inserts in a toolbox or chest designed specifically for sockets.

By placing sockets back in a storage system, you will be able to see if any of your sockets are missing when you have finished using them. This will also help prevent you from losing sockets.

Dedicated socket storage systems should allow you to organise your sockets in size order, which will make finding the correct size socket for the job much easier next time you come to use them. For more information on how best to store sockets, see: What are the different types of socket storage cases?

Is it possible to repair a damaged socket?

Sockets that have been damaged, cracked or broken should be replaced. Attempting to repair a broken socket is likely to result in a socket that is weak and likely to break again. In addition, the socket’s original dimensional accuracy may be affected, increasing the chance of rounding or damaging fasteners.

The most common causes of damaged sockets are improper use, such as using a standard socket with an impact wrench, or corrosion of the socket which affects the size of the socket and fit on the fastener.

If you are unfortunate enough to suffer a broken socket that is not covered by a warranty, it is possible to purchase individual sockets. This can be an opportunity to upgrade your socket to a better quality one such as an impact socket or one with a better guarantee or warranty.

Do sockets wear out?

Most people are unlikely to ever experience their sockets wearing out. However, any tool that rotates in contact with another object will experience some degree of wear over time. This is most likely to occur with impact sockets that are used continuously in industry.

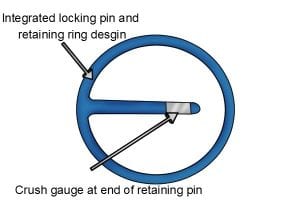

In these situations, a retaining ring and pin with a crush gauge can be used to indicate when the socket or impact wrench drive square has worn to the stage where it needs replacing.

To see how a crush gauge can be used for this take a look at What socket accessories are available?