What is a socket bit? |

||||

|

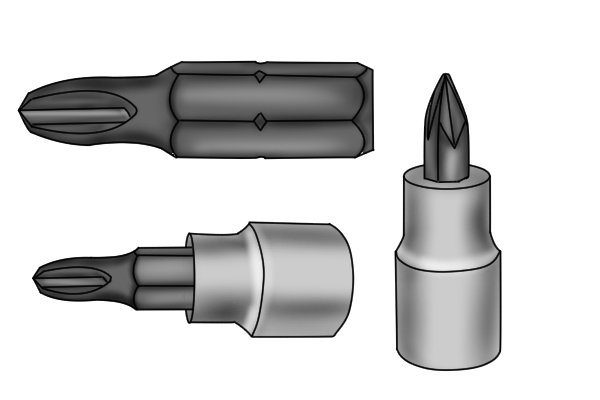

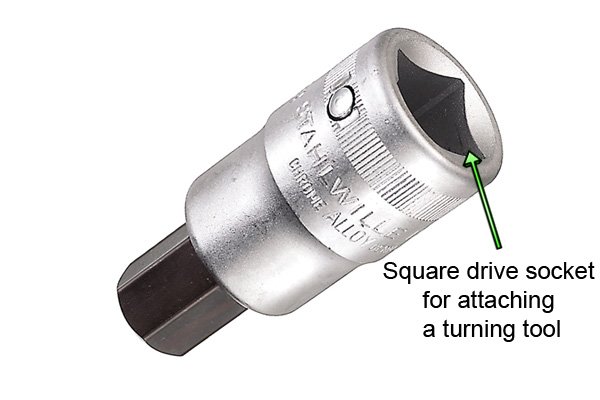

Socket bits are a combination of a bit, such as a screwdriver bit, and a hex socket. Socket bits connect to a turning tool such as a ratchet in the same manner as a hex socket, using a square drive socket. | |||

|

Socket bits will often be referred to by the type of bit they have fitted, for example a socket bit with a hex bit will often be called an in-hex socket, while ones with Torx bits are called Torx sockets or Torx bit sockets and ones with pozidriv screwdriver bits are called pozidriv bit sockets. | |||

|

The screwdriver bits used in socket bits are sized in the same way as regular screwdriver bits, for example: Philips screwdriver bits are labelled as PH and come in sizes ranging from PH0000 (smallest) to PH4 (largest). | |||

|

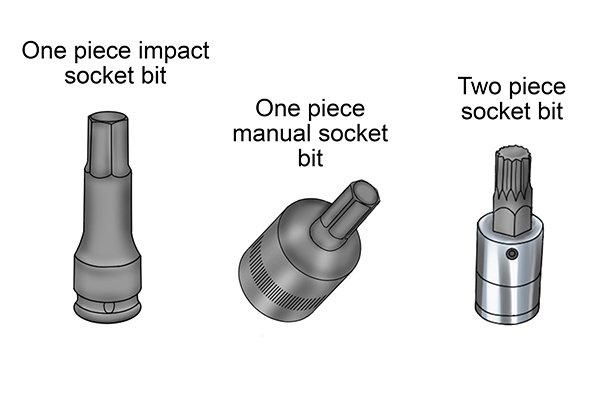

Socket bits can either have a one piece or two piece construction. | |||

|

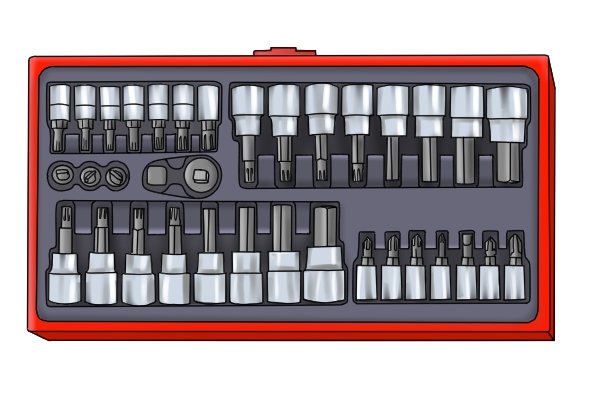

Like screwdriver bits, socket bits come in a huge variety of shapes and sizes, with each one designed for a particular style of fastener head.Socket bits can be bought individually, but are more commonly sold as a set. | |||

|

One piece socket bits are more commonly found for use with impact wrenches. As a result, like impact sockets, they tend to be made of chrome molybdenum and have a black oxide finish to them. | |||

Common types of socket bits |

||||

|

HexThese are the most common type of socket bits. The drive bit is hexagonal like a hex key. The hex drive bits can range in size from 1.5mm up to 32mm, although larger specialised sizes are available. This type of socket bits will often be referred to as an in-hex socket. |

|||

|

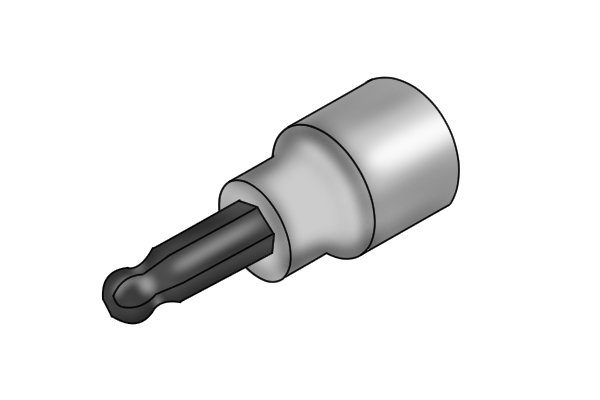

Socket ball hexThese are essentially the same as in-hex sockets, but the end of the hex key bit is rounded like a ball. This feature enables the socket bit to locate into the fastener head at angles of up to 30 degrees, allowing access to fastener heads located in awkward-to-reach areas and confined spaces. |

|||

|

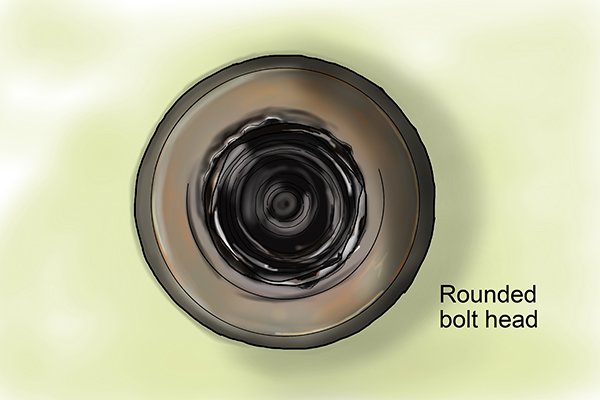

The rounded ball end, however, does reduce the contact area with the fastener head; this means that there is a greater chance of rounding the inside of the fastener head or the driver bit. As a result, less torque can be applied to a fastener with a socket ball hex as opposed to a hex in-hex socket. | |||

|

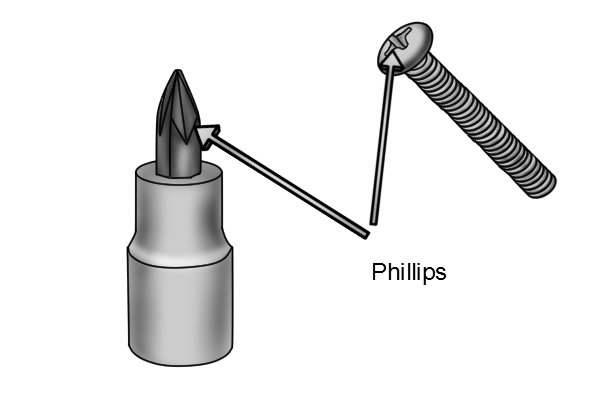

PhillipsThe Phillips was invented by Henry F. Phillips. This type of screw head was designed before torque sensing drivers, such as torque wrenches were widely available. As such, it is specifically designed to cam out (see ), preventing the fastener from damaging the workpiece and instead damages the screwdriver bit, which can more easily be replaced. Philips screwdriver bits are labelled as PH and come in sizes ranging from PH0000 (smallest) up to PH4 (largest). |

|||

|

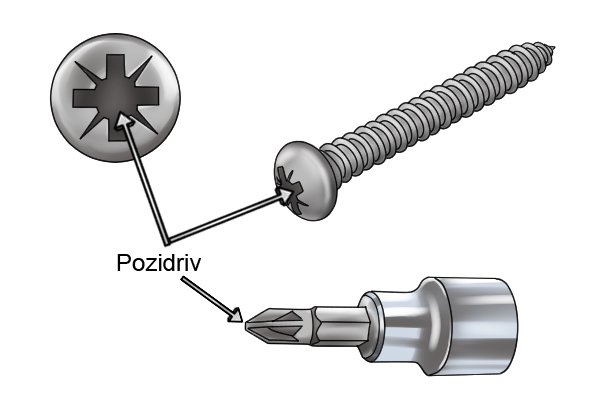

PozidrivThe pozidriv differs from the Phillips head screw in that it has a second, less well-defined cross indented into the head of the fastener. Unlike the Phillips screw and drivers, pozidriv screws and drivers have straight-sided flanks and this, coupled with the second cross indentation, reduces the risk of camming out. Pozidrive heads also allow more torque to be applied to the fastener. Pozidriv screws are often used in woodworking and aviation. To help distinguish from Phillips head screwdriver bits, pozidriv bits are labelled PZ. |

|||

|

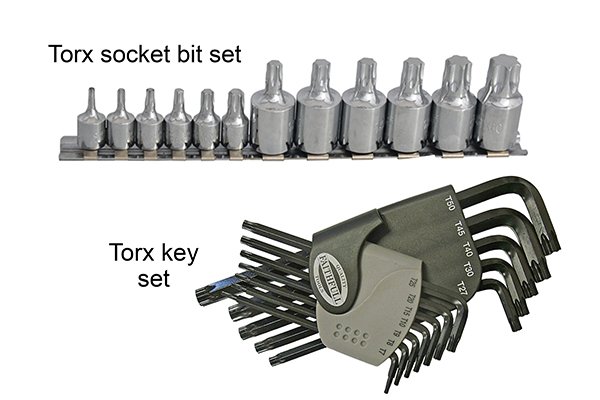

TorxTorx head socket bits bits are designed to fit and turn the heads of Torx screws. Torx bits are star-shaped with six rounded points. The Torx design allows the socket to transmit greater torque from the driver bit to the head of the screw. Torx bits have a much lower tendency to cam-out, which reduces the chance of rounding the driver bit or stripping the screw head. |

|||

|

Also, the user can apply less pressure to maintain contact between the driver bit and screw head without suffering cam-out. Therefore, torx bits help to reduce fatigue from the user constantly having to apply pressure. | |||

|

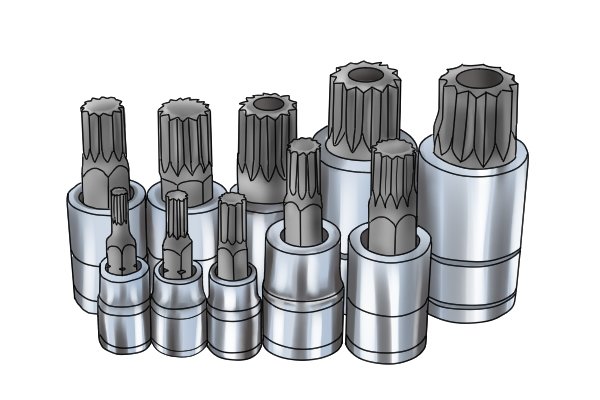

SplineA spline fastener has a twelve-pointed recess in its head. The spline design has a high resistance to camming out, making its use most common in applications that require high torque to be placed on the fastener. Common examples of where a spline fastener might be used are: vehicle cylinder head bolts, and aerospace applications that require high joint clamping forces such as landing gear. |

|||

|

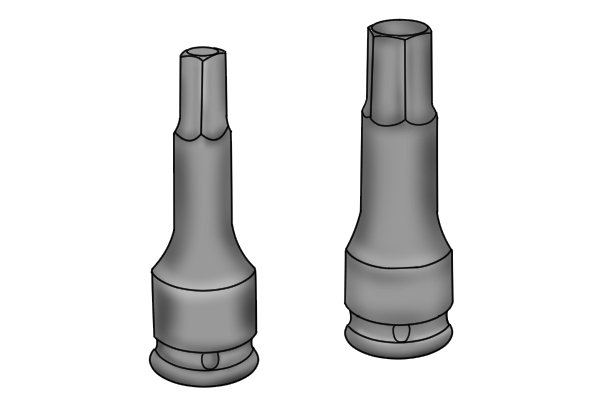

ImpactImpact socket bits are available with hex, Torx, spline and many other drive bits. They are made of the same material as impact sockets (chrome molybdenum). This is so that they can withstand the vibration and torque forces that are generated by an impact wrench without shattering. Like impact sockets, they have a black oxide industrial finish instead of the chrome finish found on other sockets. This finish, unlike chrome, will not flake off under impact or vibration, so helps to maintain the corrosion protection of the tool. |

|||

|

For more information on the different types of screwdriver bits available see our page on | |||

What socket bit sizes are available? |

||||

|

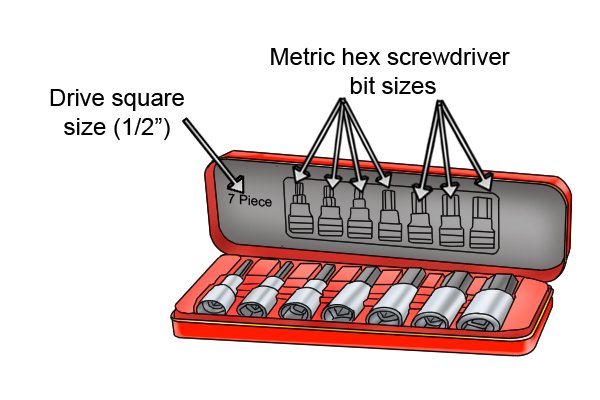

Just as with hex sockets, socket bits sizes are determined by the size of the screwdriver bit and size of the drive socket. | |||

|

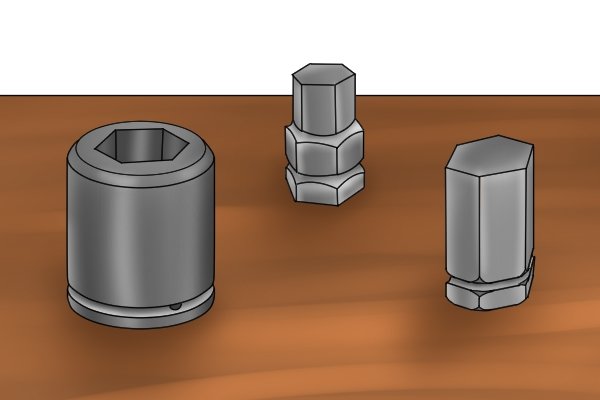

Drive sockets on socket bits can be either 1/4″, 3/8″, 1/2″ and 3/4″ in size, although the 1/4″ drive size is by far the most common.Larger drive sockets are normally found on larger socket bits where a greater torque is required to be applied to the fastener. | |||

|

It is possible to get socket bits with even larger drive sockets, but they are often made to order and only used in heavy industry so are considered to be a specialist tool. | |||

|

The screwdriver bit of a socket bit is sized according to the type of bit it has. For example, hex key socket bits are available in metric or imperial sizes and sized in the same way as a hex key would be: 5mm (H5) for metric or 3/18″ for imperial. | |||

|

Whereas, Torx socket bits are sized in the same manor as Torx screwdriver bits and keys, for example; T25, T30 etc.The size of a socket bit corresponds to the fastener head size it is designed for. So a T30 Torx socket bits is designed to fit and turn a T30 Torx screw head.

Read our guide: Different Types of Socket Bits. |

|||

|

||||

|

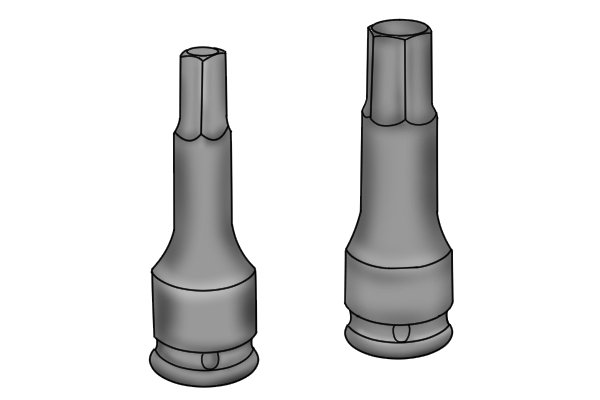

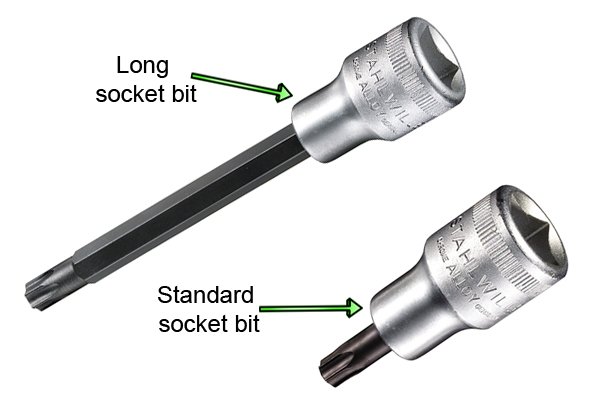

Like standard and deep length hex sockets, socket bits come in a standard length and long length.Standard socket bits will be around 40mm (1 1/2″), while long socket bits can be over 150mm (6″) long.Long bits are useful for reaching into recesses or accessing fasteners through obstructions, while standard bits provide more control in tight areas. | |||

Why would you use an in-hex socket instead of an Allen key? |

||||

|

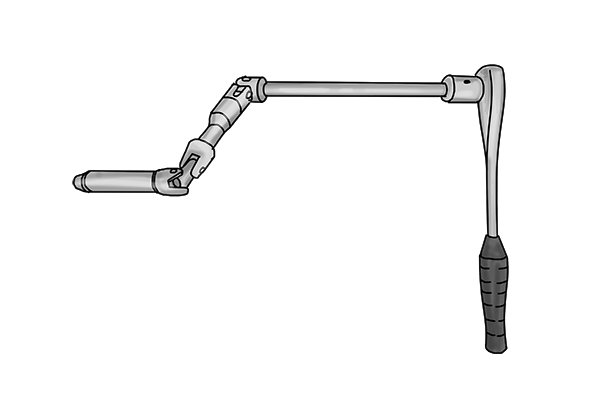

There are several reasons why you may wish to use an in-hex socket instead of an Allen key. These could include the ability to attach a ratchet with a longer handle giving you more leverage and torque on the fastener. | |||

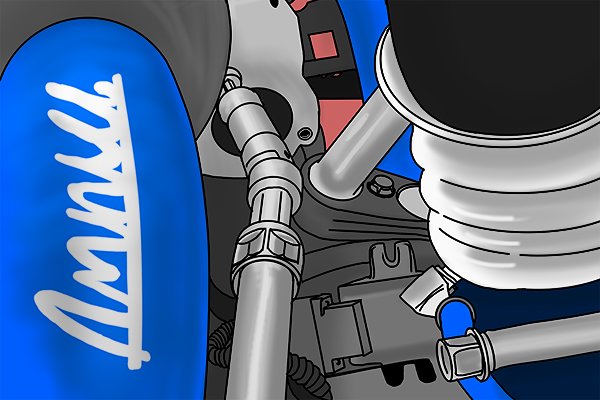

|

As you can use an in-hex socket with a ratchet, you can turn fasteners in situations where there may be objects obstructing the use of an Allen key. The large range of accessories available for use with in-hex sockets can allow you to gain access to awkward-to-reach fasteners in confined spaces that you would be unable to reach with an Allen key. | |||