What is a socket?

A socket is a tool that attaches to a socket wrench, ratchet, torque wrench or other turning tool in order to tighten or loosen a fastener such as a nut or bolt by turning it.

How to identify a socket?

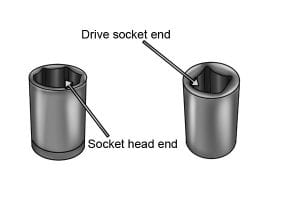

Sockets have a recessed square at one end called the ‘drive socket’ that is used to connect the socket to a wrench or other turning tool. The drive socket gets its name because it is the end that is being “driven” (turned) by the turning tool.

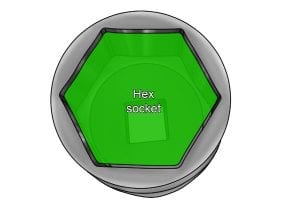

The other end of the socket is called the head and can come in a number of different shapes depending on what type and size of fastener it is designed for. The most common socket head shape is a hexagon, and sockets with these are usually referred to as hex sockets or 6 point sockets.

For more information see: What is a hex socket?

Are there other types of socket?

Some sockets, called ‘socket bits’, have a protruding male head (Male – When referring to sockets, screwdriver bits or fasteners, the male is the part that is inserted into the corresponding female part.

For example, a torx screwdriver bit of a socket bit is the male part that is inserted into the female head of a fastener in order to turn/drive it into the work piece.

This is used for driving fasteners with a female recess (Female – With reference to sockets, screwdriver bits and fasteners, the female is the part that the male fits into.

For example, when tightening a nut or bolt with a hex socket, the bolt head or nut is the male part which locates into the female socket head, allowing the nut/bolt to be turned, tightening or loosening it.) in their head.

For more information see: What is a socket bit?

Which fasteners can sockets be used on?

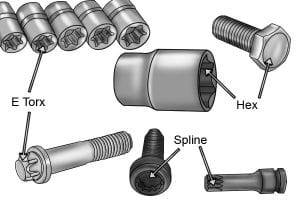

The shape of a socket’s will determine the particular fastener it is designed to turn.There is a socket for virtually every type of fastener, but you must select the corresponding socket for the fastener you wish to turn.

For example, hex and bi-hex sockets are designed to turn six sided nuts and bolts. E Torx sockets are designed for use with E Torx bolts, while spline in-hex sockets are designed for use with spline headed bolts.

For more information see: What are the different types of socket?

Why would you use a socket instead of a spanner?

Sockets used in conjunction with turning tools have a number of advantages over other fastening tools such as spanners.

Sockets are cheaper to produce as they require less material to make than tools such as spanners. However, you will also need some sort of turning tool to go with your socket set, which may make the total cost more expensive depending on the turning tool.

Sockets take up less space than spanners, even when you account for a turning tool as you only need one turning tool to go with your socket set. This means it’s easier to carry a wide selection of different sizes with you.

Sockets can be used with ratchets to save time and effort particularly when tightening or loosening a fastener that has limited access.

Sockets make contact with bolt heads and nuts in six positions instead of two, allowing more torque (see Torque – Torque is the turning force of an object, and can be calculated by multiplying the force applied by the distance along the length of the lever used to apply it. Torque can be presented in either Newton metres (Nm) or pounds feet (lbft).) to be applied to the fastener and reducing the chance of rounding it.

Deep sockets and extension bars are available for reaching recessed or hard-to-reach fasteners, which would not be possible with a spanner.

Sockets are most commonly sold as a set. This can often be an advantage as you only need one turning tool and a set of sockets to do the job of many spanners. However, it is also possible to purchase sockets individually, although this is less common.