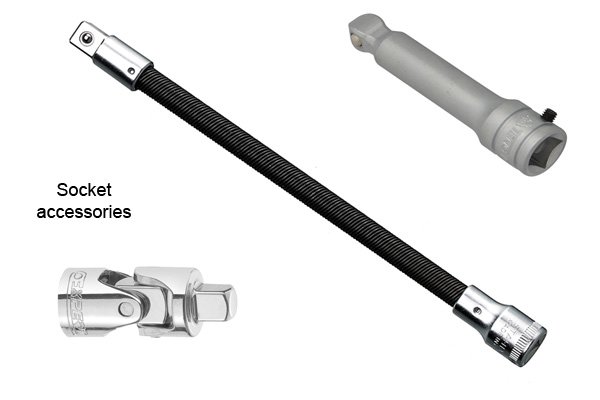

What socket accessories are available? |

||||

|

Socket accessories are used to increase the versatility of sockets. There are accessories available that are designed to extend the reach of sockets, help gain access to confined or awkward spaces, or protect the workpiece. | |||

Extension bars |

||||

|

Extension bars fit between a turning tool (e.g. ratchet or bar) and a socket to give a longer reach, and can be useful for accessing fasteners that may be recessed, or have obstructions in the way of them. They will fit any turning tool that can connect to the socket.Extension bars can be purchased in a range of different lengths from 50-300mm (2″-12″) and can be combined to achieve the exact length required. | |||

|

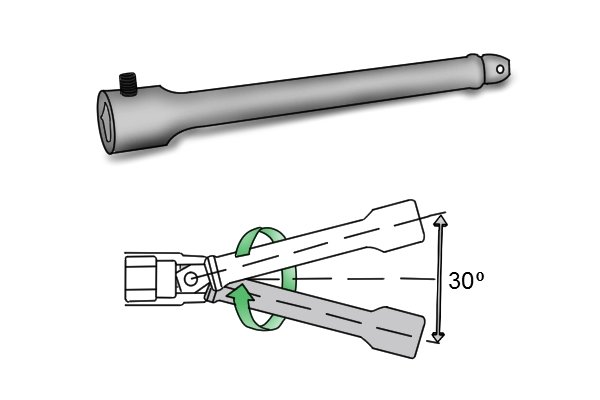

Wobble extension barsThese are extension bars with a slightly rounded drive square enabling them to turn the socket whilst being connected at an angle. This means you can turn fasteners in awkward, hard-to-reach places. |

|||

|

Flexible extension barsFlexible extension bars can be used to reach through areas that are obstructed or around corners. Some flexible extension bars will only allow you to turn fasteners in one direction, so make sure the one you are buying will turn the way you need it to or buy one that works in both directions. |

|||

|

Why would you use an extension bar instead of a deep socket?Extension bars are longer than deep sockets and can be combined together to give even greater length. This allows greater reach into cylinders or through obstructions than a deep socket could achieve. Flexible and wobble extension bars also allow access to fasteners at an angle that is not possible with a deep socket. |

|||

Adaptors or converters |

||||

|

Adaptors fit between a turning tool (e.g. ratchet, bar etc.) and a socket. They allow you to connect a turning tool with a drive square that is smaller or larger than the drive socket size of your socket e.g. ½” to ¼” drive, or ¼” to ¾” drive.Several adaptors may be used in order to allow any size turning tool to be used with any size socket. | |||

Universal joints |

||||

|

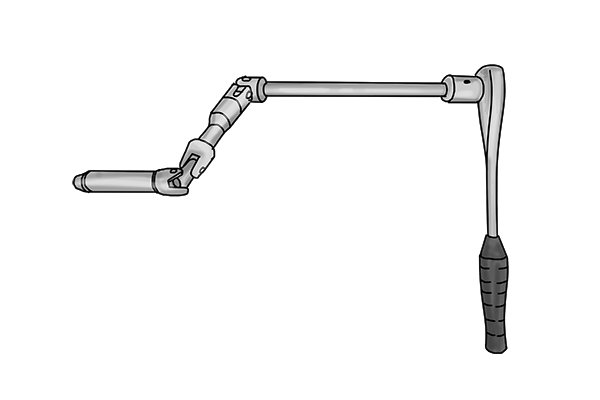

Universal joints are placed between the turning tool and a socket (or extension bar).The universal joint allows the socket and/or extension bar to twist and turn in any direction, enabling the rotating motion from the turning tool to be transferred at an angle through the universal joint, to the socket. | |||

|

Universal joints are often used in conjunction with an extension bar to reach fasteners that may be obstructed or in awkward and confined spaces. Universal joints are stronger than a flexible extension bar and so allow you to apply more torque through them to the socket and fastener. Find out more about what are sockets used for? | |||

Socket rail tracks |

||||

|

Socket rails are used with socket clips to secure and store sockets.If you are going to purchase sockets individually instead of buying a complete set, you may wish to get some socket clips and a socket rail to keep them together and decrease the chance of one becoming lost in your toolbox. | |||

Socket clips |

||||

|

Socket clips slide onto socket rails and allow sockets to be attached by clipping into the drive socket recess. When buying socket clips, make sure you get the correct size to fit the drive socket on the socket you want to attach them to. | |||

|

||||

Retaining rings & pins |

||||

|

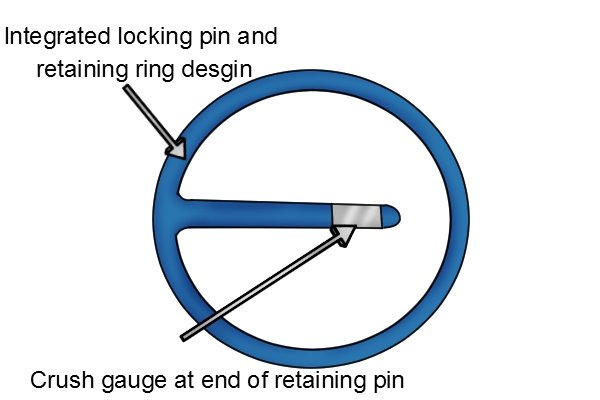

These are used on larger impact sockets to secure them to the powered impact wrench.The pin fits through the hole at the side of the drive socket and the retaining ring locates into the groove around the base of the socket, thus preventing the retaining pin from falling out. Some designs now incorporate the pin into the retaining ring. | |||

|

||||

|

Retaining pins are also available with a crush gauge that is used to indicate when the drive socket has become worn and the socket needs to be replaced. | |||

|

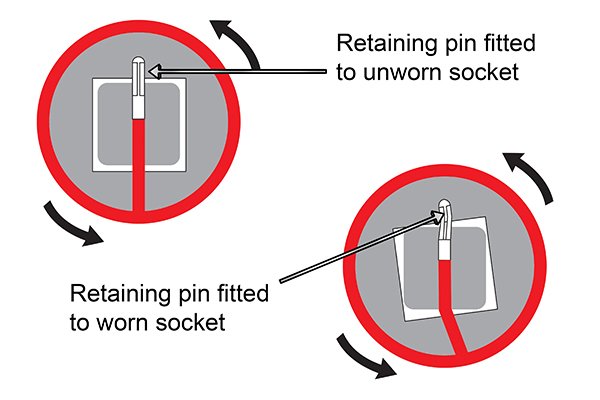

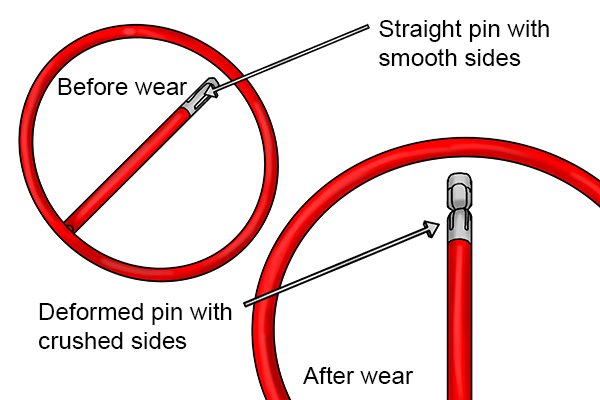

How does the crush gauge work?Once a socket or drive tool become sufficiently worn they will no longer rotate tightly together, and will begin to slip. As the drive square of the impact wrench begins to slip inside the drive socket of the impact socket, it will deform and mark the “crush gauge” on the retaining pin. |

|||

|

When the retaining ring and pin are removed, the deformed marks left on the “crush gauge” indicate that the socket or impact wrench drive square need replacing. | |||

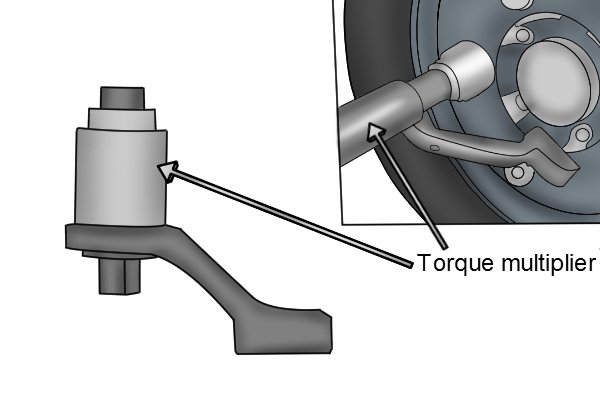

Torque multiplier |

||||

|

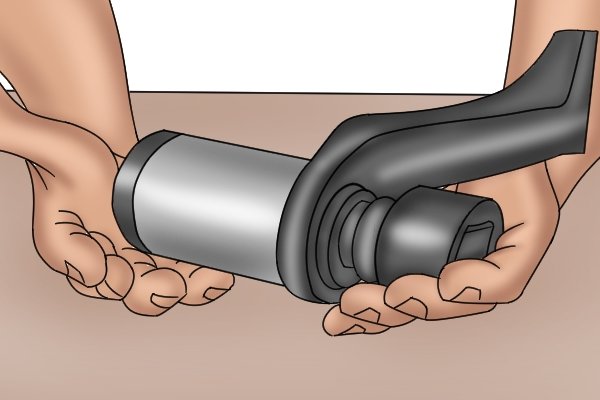

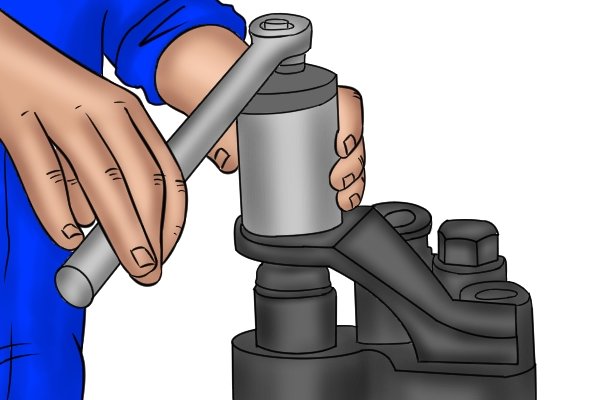

As the name suggests, a torque multiplier multiplies the torque (turning force) a user exerts on it before applying the increased torque to the socket. A torque multiplier will have a stated ratio, e.g. 3:1, meaning the torque multiplier will deliver three times as much torque as the user inputs, via an internal system of gears.Torque multipliers are available in two sorts: one looks like a ratchet or torque wrench and is used in place of a torque wrench, whilst the other is designed to attach to a torque wrench. | |||

|

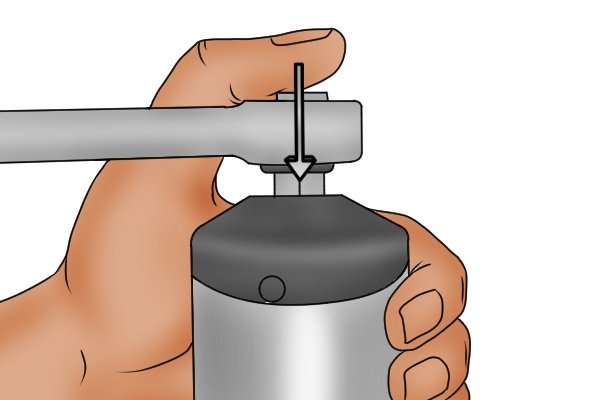

The torque multiplier has a square drive for attaching to the socket. A torque wrench is then connected to the drive square of the torque multiplier if it does not already have an inbuilt ratchet handle. | |||

|

The torque setting on the torque multiplier or torque wrench is then set. If the torque multiplier has a ratio of 3:1, then you would set the torque on the torque wrench to ⅓ of what you want to tighten the fastener to. | |||

|

The socket is then placed on the fastener and turned with the torque wrench as you would normally do. The internal gearing system of the torque multiplier then multiplies the torque from the user before applying it to the socket and fastener. | |||

|

Torque multipliers are frequently used on farm equipment to tighten and remove large nuts and bolts. | |||

Protective anti-mar socket covers |

||||

|

Protective anti-mar socket covers look very similar to insulated sockets, however these do not offer protection against electrical shock; instead, they protect a workpiece that has a polished, chrome or delicate surface from being scratched by the socket as it tightens fasteners.They are made of plastic and fit over the outside of the socket allowing the socket to spin within them.They are also useful as they are less likely to get stuck. If you do ever get your socket stuck with an accessory read out guide on how to seprate a socket that is stuck. | |||

|

As the plastic cover extends slightly beyond the end of the socket, it makes contact with the workpiece instead of the socket. The plastic cover stays stationary while the socket spins within it turning the fastener. Because the spinning socket does not make contact with the workpiece it avoids scratching the workpiece surface.They are available in drive sizes ¼” – ½” to fit sockets from 10-18mm and extension bars from 50-300mm (2″-12″) in length. | |||