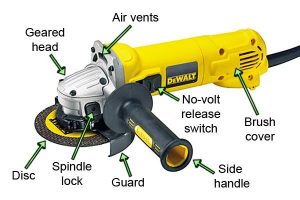

Introduction to DeWalt Angle Grinders

DeWalt angle grinders are characterised by their durable build and high quality finish. Many models have special features including:

Dust Ejection System

Anti-Vibration Handle

Overload Protection

Soft Start

Keyless Guard

Pop-Off Brushes

Sealed Bearings

Low Profile Case

Quick Disc Change

Dust Ejection System

One of the biggest problems for the smooth operation of angle grinders is dust being pulled into the motor by the cooling fan. To prevent this, DeWalt has introduced a patented dust ejection system that diverts most of the dust particles away from the motor and forces them out of the angle grinder housing.

Anti-Vibration Handle

Anti-vibration handles help to improve both comfort and accuracy for the user, by reducing vibration by up to 70%. A rubber damper provides a cushioning barrier between the spindle and the handle, making it easier to control and manoeuvre the grinder.

Overload Protection

Angle grinders can become extremely hot, especially when tackling large or difficult jobs. Overload protection is a useful safety feature that will prevent the machine overheating by cutting off power to the motor until it has cooled down.

Soft Start

Another beneficial feature is a soft-start function. This is commonly found on larger angle grinders and makes the tool easier to handle on start-up. The motor gradually builds up to its maximum running speed, so that it does not suddenly ‘kick’ immediately after it is turned on.

Keyless Guard

Safety guards on DeWalt angle grinders can be fitted, removed and adjusted quickly and conveniently without the use of an additional tool. This feature is particularly useful in a workshop environment where an angle grinder is likely to be adjusted repeatedly to adapt it for a range of applications throughout the working day.

Pop-Off Brushes

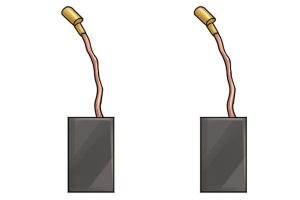

When the carbon brushes become worn down and need to be replaced, they will break contact so that the angle grinder shuts down automatically, saving the motor from damage.

Sealed Bearings

Smoothly rotating bearings are vital for the motor, so they are sealed off to safeguard them from any dust that enters the angle grinder housing. For extra protection there is an additional circular plastic seal placed between the bearings and the motor.

Low Profile Case

DeWalt angle grinders are housed in slim, streamlined cases to make them lightweight, versatile and easy to use in tight spaces. They are also more comfortable to hold for long periods of time.

Quick Disc Change

DeWalt’s keyless, quick change disc release system is a great time saver. You don’t have to use any tools to install and remove the discs or backing flanges, which makes switching between attachments a fast and simple process.

What other features do DeWalt angle grinders have?

The reason why DeWalt have arguably the best angle grinders available on the market is that they offer a lot more than just standard models. In this next section, we look at what other features are available in DeWalt angle grinders.

Geared Head

The angle grinder head is positioned at the front of the tool and contains a set of bevel gears which deliver energy from the motor to the spindle (a rod around which the disc rotates). On the front of the head is an arrow that indicates the direction in which the spindle will rotate (in this case, clockwise).

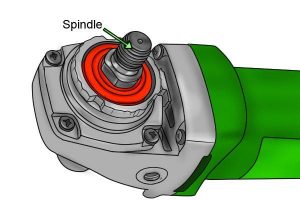

Spindle

The spindle is positioned at a right angle to the motor and turns at high speed in order to drive the attachment installed. Most angle grinders have a spindle with an M14 thread pitch. This means that the spindle has an outer diameter of 14mm.

Spindle Lock

The spindle lock is an important safety feature, as it prevents the spindle from spinning while you’re installing or removing a disc or other attachment. Always switch off and unplug the grinder before operating the spindle lock, to avoid any damage to the machine or injury to yourself from flying attachments. To engage the lock, just hold the spindle lock button down and rotate the spindle until it won’t turn any further.

Disc

An abrasive disc, or wheel, is secured on the spindle of the grinder with a special nut. A range of discs or other attachments can be fitted onto the spindle to adapt the angle grinder for different grinding, cutting and polishing applications. These are normally available to purchase separately.

All grinding and cutting discs will have a maximum speed at which they can be used safely. This is printed on the front of the disc.

You should compare this figure with the highest operating speed of your angle grinder. Look for a disc with a maximum speed that is equal to, or more than, the maximum speed of your grinder. Never use a disc if its safest operating speed is less than that of your grinder, as it is likely to shatter when the tool reaches maximum speed.

Before you fit a cutting or grinding disc, remember to check its expiry date. A disc that is out of date may break up when you use it.

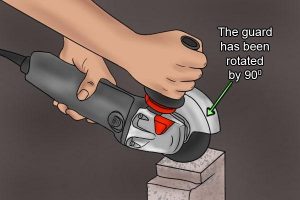

Guard

The guard is a safety feature that protects you from shards or grit that could fly from the wheel of the tool during use. You should always match the type of guard to the accessory – for instance, a type 14 wheel would require a type 14 guard.

You can rotate the guard around the cutting wheel to suit the position in which you’ll be using the angle grinder. You should alter the position of the guard to correspond with the position of the side handle, which can also be adjusted to suit different users and applications. The guard should sit on the same side as the handle to protect you from sparks or debris that are likely to fly from the disc.

Side Handle

The side, or auxiliary, handle helps to stabilise the tool so that it can be used more safely. The handle is secured to the body of the angle grinder by an integral screw and can be installed on either side of the gear head. This means that the machine can be used by both right- and left-handed users. You can also change it over if you find the handle is getting in the way at certain angles, making the grinder more versatile.

Brush Cover

Carbon brushes are used to transmit current to the angle grinder’s motor, and have to be replaced periodically. You can reach the brushes by unscrewing a cover on the main body of the tool.

Air Vents

The air vents prevent the angle grinder’s motor from overheating – a vital role, as the machine can get very hot while in use. It is very important that the vents are kept free from dust and debris.

No-Volt Release Switch

The paddle-operated no-volt release switch features a safety lock-off to prevent you from accidentally switching the grinder on before you’re ready to use it, and has to be reset before the power comes on.

You can either push the switch halfway so that the machine only works when you’re applying pressure, or move the switch further along to lock it in position.