Angle Grinder Speed and Power

Two of the most important features when it comes to picking an angle grinder is the speed and power. In this article we walk you through why these are so important and how to choose the best angle grinder for you.

Speed

The speed at which you need your angle grinder to operate will depend both on the task you are using it for and the material you’re working with.

Whilst cutting tasks require an angle grinder to be running at full speed, grinding applications are carried out at a slightly slower rate, and finishing tasks, like polishing, require lower speeds still.

If you intend to use an angle grinder for more than one of these applications, you will need to purchase either a variable speed version or a couple of different models that are capable of running at the speeds you require.

Mini angle grinders rotate faster than large ones due to the smaller disc diameter.

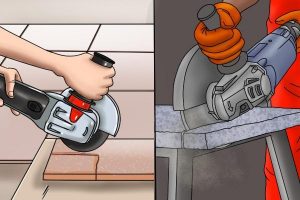

Cutting

Compared with other applications, cutting tasks will require your angle grinder to run faster. Because materials have distinct properties, they require different speeds to get the best results.

Generally, the harder the material, the greater rpm required. To cut through paving stones, an angle grinder with a no-load speed of between 3,500 and 7,000rpm would be best.

However, to cut through hard materials, like most metals, a high cutting speed is required.

The exact number of rpm will depend on the size of your grinder, but should be between 7,000 and 11,000rpm (usually your machine’s maximum operating speed).

Cleaning and Polishing

Cleaning and polishing tasks, including paint and rust removal, which are completed with an angle grinder and a wire wheel must be carried out with the machine running at a relatively slow speed (around 3,000rpm).

This is because if the spindle were to spin any faster, parts of the brush could separate and cause injuries.

If you’re using a polishing pad or flap wheel to remove a surface coating from stone or metal, it is recommended that your angle grinder runs at around 4,000rpm.

Sanding

If you’re using your angle grinder as an alternative to a sanding machine, the speed at which the tool should run will depend on the amount of material you want to remove.

The smaller the rpm, the less material the sanding or flap disc will eliminate. Usually, sanding is carried out with an angle grinder operating at between 3,000 and 4,000rpm.

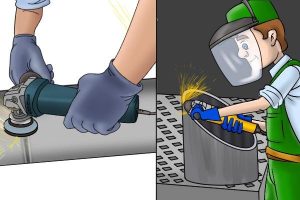

Grinding

For grinding tasks, your angle grinder will need to be running at a much faster rate, in the region of 5,000-8,000rpm.

The material you’re working with will determine the precise speed needed – the harder the workpiece, the faster you’ll need the grinder to run.

Power

Along with speed, the power of an angle grinder will determine how effectively the machine is able to cut or grind.

The tool’s power is reflected by its wattage, amp rating and, for cordless versions, voltage. These values vary considerably from model to model and are important to bear in mind when making a choice.

Wattage

In the UK, the wattage of an angle grinder is the main indicator of the power of its motor. DeWalt angle grinder wattage can range from 900W to 2,400W.

This value usually reflects the grinder’s size, as larger cutting and grinding discs require more power.

Angle grinders with a greater wattage are more capable of maintaining higher spindle speeds under load. As a result, they are recommended for cutting tasks or other heavy-duty applications.

AMP Rating

An angle grinder’s amp rating, or amperage, is the maximum amount of current that the tool is able to carry continuously. For much of the time the machine will draw less current than this. In particular, when it is running under no load the motor will turn faster and consume less power.

More powerful grinders have motors that draw between 5 and 9 amps of current, and some heavy-duty models can have amp ratings as high as 15. These angle grinders are better able to handle tougher cutting and grinding applications as their motors are less likely to overheat under load.

For less intensive jobs, a smaller angle grinder with a lower amp rating of around 3 or 4 is likely to be sufficient. Because it can be calculated using the voltage and wattage of the machine (values provided by the manufacturer), the amperage of an angle grinder is not always stated in the product specifications. To work out the amp rating of your machine, simply divide its wattage by its voltage.

What does Ah mean?

Cordless angle grinders are frequently categorised by their Ah rating. This stands for ampere-hour, and is the measurement of time it takes for a battery to run flat. Obviously, the higher the Ah rating, the longer the battery is likely to last – although the exact time will vary, depending on what you’re using the tool for.

Voltage

Voltage, also known as electrical potential energy, is the force of an electric current.

For cordless angle grinders, voltage is one of the main determinants of their power. When thinking about the power of corded models however, voltage is less significant compared with wattage.

Corded Angle Grinder

Like other mains-operated power tools, corded angle grinders are available with a voltage of either 240 volts or 110 volts. The voltage of an angle grinder indicates where it is safest to use it: in a domestic environment or out on a work site.

110V Angle Grinder

Most tradespeople use angle grinders with a voltage of 110V. This is because 110V is considered to be a much safer form of electricity, and therefore best for a work site where there is a much greater risk of injury due to electric shock.

These grinders produce the same amount of power as 240V machines but use a lot more current.

In the UK, electricity supplies of 110V are provided through a step down transformer, which reduces the mains voltage of 240V to a less dangerous 110V. If you are thinking of purchasing a 110V angle grinder to use on site, you will also need a transformer.

240V Angle Grinder

Angle grinders with 240 volts are designed to run directly off mains electricity. They are most suitable for domestic use, inside the house, where there are fewer potential hazards.

Corded angle grinders will only work properly with the voltage they have been designed for. Before purchase, it is critical that you check that the voltage of the angle grinder corresponds with the voltage of your power supply.

For instance, if you plug a 110V grinder into a 240V socket, it is likely that its internal parts will melt and your tool will be destroyed.

Cordless Angle Grinders

When it comes to cordless angle grinders, voltage is the main indicator of power. The higher the voltage, the more power the machine is capable of exerting.

Most angle grinders have a voltage of 18 volts, but DeWalt also produce a more powerful model with 36 volts.

Which power rating is best?

If you are planning on using your angle grinder extensively, it is best to choose one with a higher wattage, of at least 800W.

These machines are less likely to overheat as their powerful motors will not be working as hard as less powerful angle grinders.

On the other hand, if you are looking to buy an angle grinder for a one-off light-duty DIY task, the power of the machine may not be as critical. For household tasks, a 1000W motor should be sufficient.

Heavy-duty tasks such as cutting through hard metal will require a more powerful motor, with a higher wattage.

For light-duty tasks such as deburring, polishing or cutting softer materials, a large motor is not as important.