How to use a DeWalt Angle Grinder?

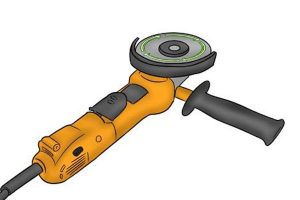

Before you go straight into using a new angle grinder, even if you are experienced, you should always take care. Our advice is to always read the safety booklet that comes with the power tool and ensure that you are aware of all the features and safety mechanisms on your new DeWalt angle grinder.

Safety Tips

Gear Up

Protect yourself from showers of sparks by wearing a full face visor or safety glasses, gloves, long trousers and sturdy shoes. Ear defenders are advisable too, as the machines are quite noisy. If you’re working with stone or mortar, you should also wear a respirator or dust mask.

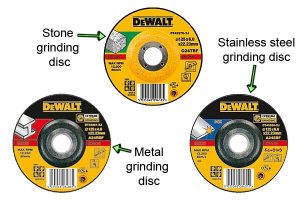

Check Disc

Before carrying out any application with an angle grinder, make sure that you inspect the abrasive disc you plan to use for any cracks or other signs of damage. Never use a faulty or worn-down disc as it might shatter.

Check Work Area

Check the area in which you will be working for any flammable materials and determine where the sparks produced will fly. Make sure that the angle grinder safety guard is in the correct position to protect you from these sparks during operation.

Adjusting the Safety Guard

Never use a grinder without a safety guard! The guard creates a barrier between you and the dangerous end of the tool, and needs to be adjusted to the right position beforehand so that it will direct sparks and debris away from your face and body during use.

Most DeWalt angle grinders now have a tool-less, also called keyless, guard which can be easily adjusted without the need for a screwdriver or spanner.

The guards of some grinders can be simply twisted manually until they are positioned correctly. Others have a clamping lock at the front of the tool which can be undone to allow the guard to move.

Step 1 - Release Clamping Lock

First make sure that your angle grinder is not connected to the mains or, if it’s cordless, remove the battery. Release the clamping lock by pulling the lever away from the spindle.

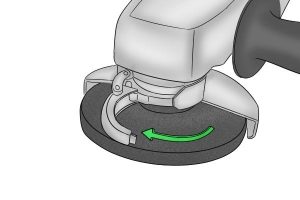

Step 2 - Rotate Safety Guard

Turn over the tool so that the spindle is facing upwards, then rotate the safety guard clockwise until it’s in the right place. The guard should be positioned between your hand (when holding the auxilliary handle) and the grinding or cutting disc.

Step 3 - Re-fasten Clamping Lock

When the guard is where you want it, push the lever back towards the spindle to fasten the clamping lock and secure it in position.

Wonkee Donkee Top Tip

After installing any cutting or grinding disc, it is important to run your machine with the newly-mounted wheel before you start cutting or grinding.

Turn the angle grinder on and wait until the disc or other attachment reaches full speed, then apply the disc to the workpiece.

How to grind or sand with an angle grinder?

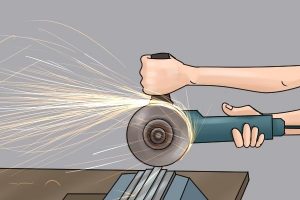

Hold the grinder firmly with the face of the disc, not the edge, against the workpiece. Do not press hard. Let the grinder do the work. In general, try and keep the face of the disc at an angle of about 15 degrees to the surface of the workpiece.

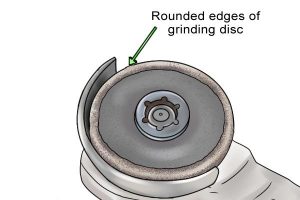

If you are using a new grinding disc, only work the grinder towards you to begin with. When the edge of the disc has been rounded off, you can move it both towards and away from you. This will ensure that the disc grinds evenly and the new, fairly sharp edge doesn’t immediately gouge the workpiece.

How to cut with an angle grinder?

For cutting jobs, the sharp edge of the cutting disc is employed rather than the face. The angle grinder should normally be held at 90 degrees to the workpiece (unless another angle is required for a particular task).

Don’t apply too much pressure to the grinder when cutting material. Cutting discs are made very thin to obtain maximum sharpness, so any unnecessary force could cause them to break. The weight of the angle grinder alone will apply enough pressure to the workpiece.

What if the angle grinder overheats?

When an angle grinder is running without load at full speed, the cooling efficiency of the motor is at its maximum. However, when the tool comes into contact with any workpiece and is forced to slow down, this cooling efficiency will be reduced and you will be able to feel your grinder heat up rapidly.

This is because the motor is drawing more current, so is less able to cool itself down.

If your angle grinder does become too hot, it is very important that you do not turn off your machine as this could cause it to burn out.

Instead, take the grinder away from the workpiece and let it run at full speed without load for between 10 and 20 seconds.

This will allow the fan inside the tool to direct air through the machine and cool down the motor and carbon brushes to a safer temperature.

To prevent overheating, particularly during demanding jobs, rest your angle grinder every few minutes to allow it to cool itself. As you use the tool, you will get a feel for how often this is required.

Overheating is more likely to occur if you’re working with particularly tough materials, or when there has been a build-up of dust within the motor.

DeWalt’s dust extraction system helps to eliminate contamination by channeling debris out of the grinder’s housing.