What are marking out gauges made from? |

||||

|

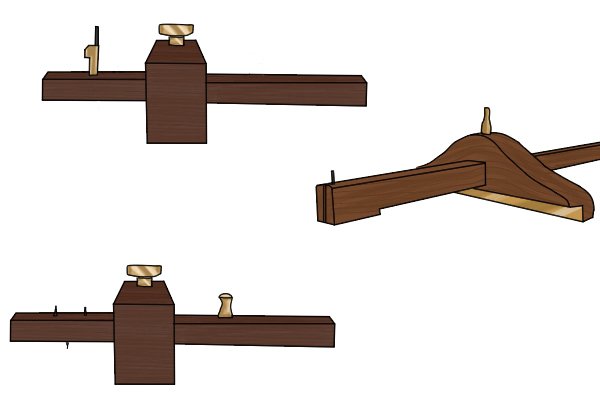

Marking gauges are available in a variety of materials, but were originally made out of wood. Today this is still the most common material used for the bulk of tool. | |||

|

All gauges, apart from the wheel gauge which is made from aluminium, are available made from wood, which can be one of three varieties: | |||

Beech and maple |

||||

|

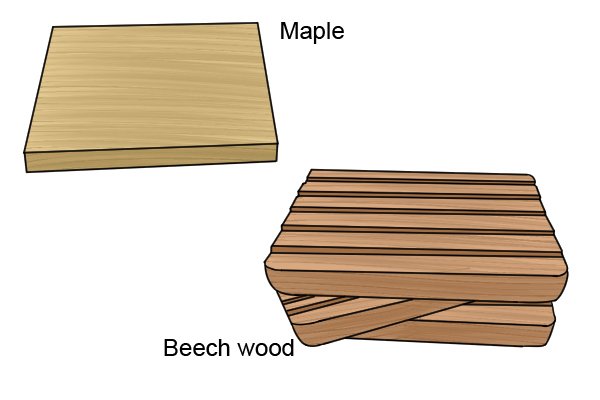

The most common woods used are beech and maple, both hardwoods, which are strong and can withstand prolonged wear and tear. These woods are often used in tool manufacture because of these qualities. Beech wood has a lighter colour than maple but other than this the materials are very similar. | |||

|

As maple is native to North America, it is not as widely available in the United Kingdom as beech, meaning marking out gauges made from maple may be slightly more expensive. | |||

Rosewood |

||||

|

The gauges can also be bought made from rosewood, which has a dark colour ranging from deep reds, browns and purples. Rosewood is a very rare wood and this makes it the most expensive out of the three, sometimes almost triple the price, however many would say it has the best look and a finish of quality. | |||

|

As well as a quality look, rosewood also has a strong resistance to rot and water damage that the other woods do not. The rosewood gauges are definitely more of a luxury tool to be invested in if you are woodworking enthusiast. | |||

Plastic |

||||

|

There are marking gauges available made with a plastic body. This tool’s main advantage is that it is cheaper than the wooden models, so it is useful if you only need the tool for one project or little use. The plastic model, however, is not as strong and does not have the weight of wood which is helpful when guiding the tool across the workpiece. | |||

Fittings |

||||

|

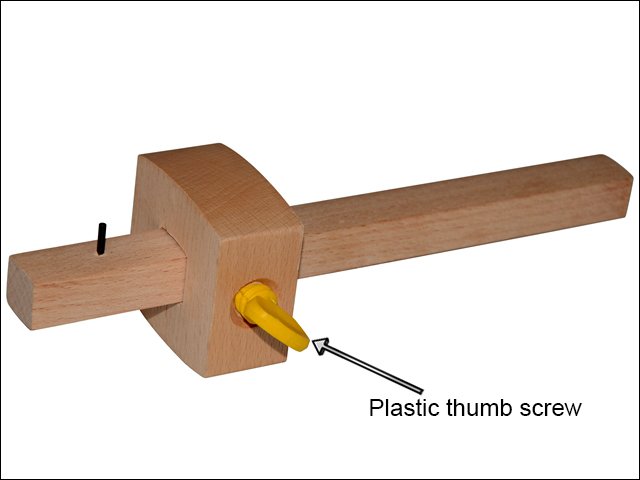

The fittings on marking out gauges can be made from either plastic or brass.

PlasticThe cheaper models, such as the plastic gauge and some beech gauges, simply have a plastic thumb screw. This thumb screw works efficiently but can be more susceptible to becoming loose over time which brass screws tend not to do. |

|||

|

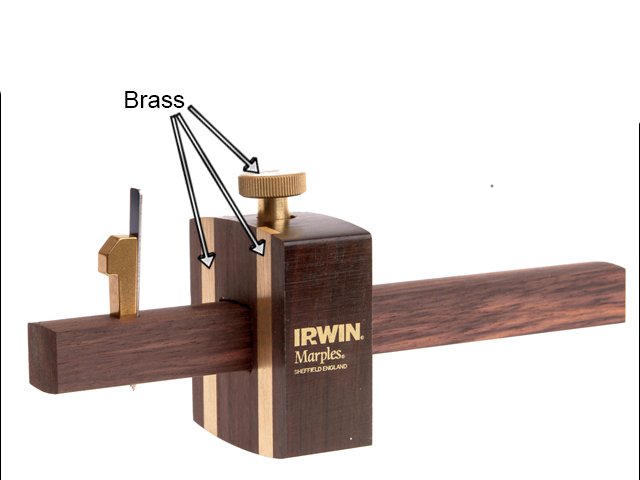

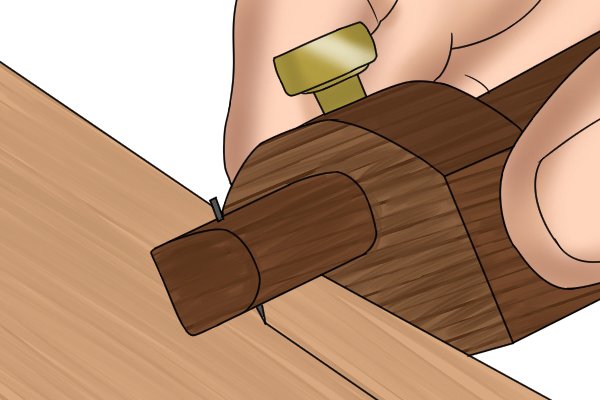

BrassMost wooden marking out gauges use brass for the thumb screw as well as on the fence. Brass is a strong but relatively cheap metal which contrasts against the wood colouring. Brass panels are used on the fence to stop the work surface and tool marking and scratching each other. |

|||

Aluminium and brass |

||||

|

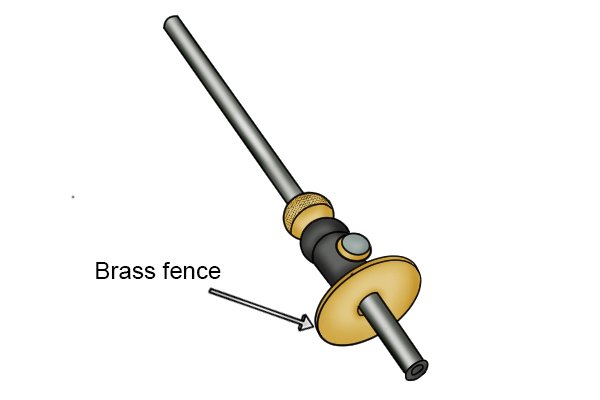

Wheel gauges have a completely metal frame. The body is made from aluminium as it is lightweight but also strong and corrosion resistant. It is important that the tool is not too heavy so that the user can easily guide it over the work surface.

For more information see What is a Wheel Gauge?

|

|||

|

Like the wooden marking out gauges, wheel gauges also have a brass fence as brass is non-marring meaning it won’t damage the work surface. | |||

Hardened steel |

||||

|

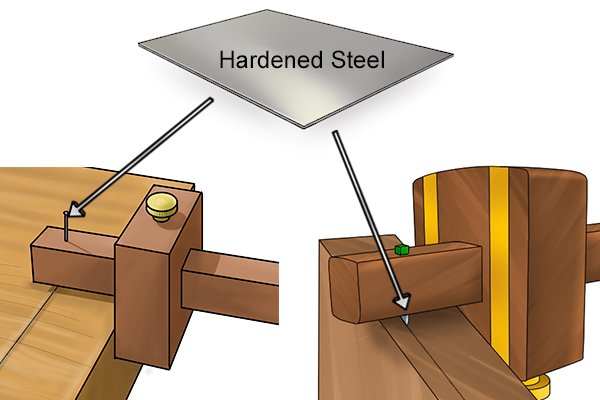

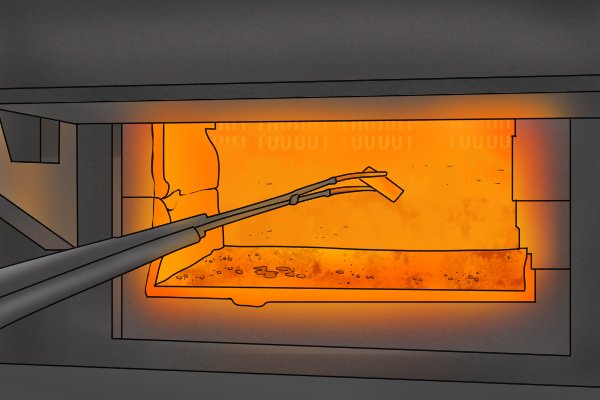

The pin and blades on all marking out gauges are made from hardened steel, which is steel that has been heat treated to make it tougher and more wear resistant. | |||

|

Steel is hardened by heating the intended spot until it reaches a temperature of between 600 and 800°C. It is then immediately cooled by being placed into cold water. | |||

|

It is important that the blade and pin of a marking out gauge is strong as it must be able to easily carve a line through the wooden, or sometimes metal, work surface.

The steel also needs to be hard-wearing because as soon as the tip of the blade or pin begins to get dull, the line becomes thicker and less accurate. |

|||