What is a deburring tool? |

||||

|

|

||||

|

A deburring tool is designed to remove sharp edges and burrs from drilled holes and pipework.Burrs and sharp edges can form on workpieces during manufacturing processes like drilling holes and it’s often beneficial to remove them. To find out why, see our page:

There are two types of deburring tools: |

|||

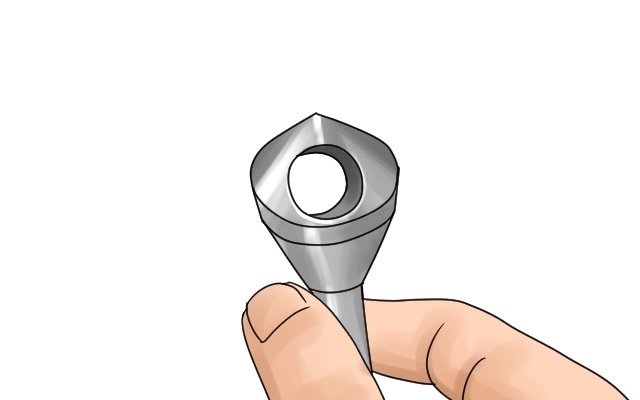

Deburring cutters |

||||

|

Deburring cutters are used in machines (e.g. pillar drills, lathes) and hand-held drills and are used to remove burrs from edges. | |||

|

||||

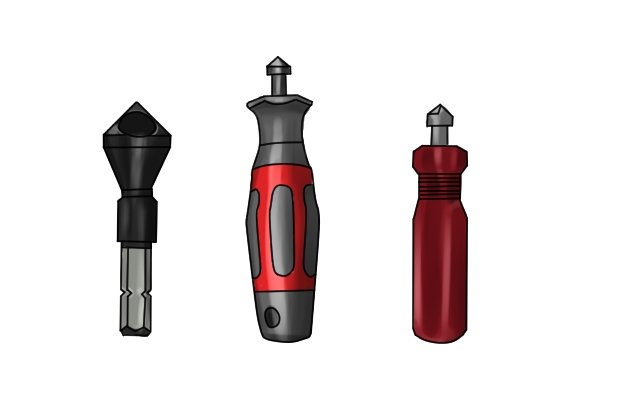

Hand-held deburring tools |

||||

|

Hand-held deburring tools are designed to be used by hand to remove burrs from the edges of holes. | |||

|

Both tools usually come in one or two different sizes and are typically made from HSS (high speed steel). | |||

Deburring tool applications |

||||

|

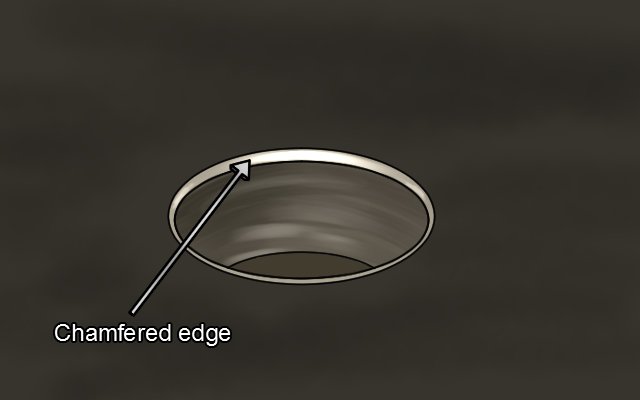

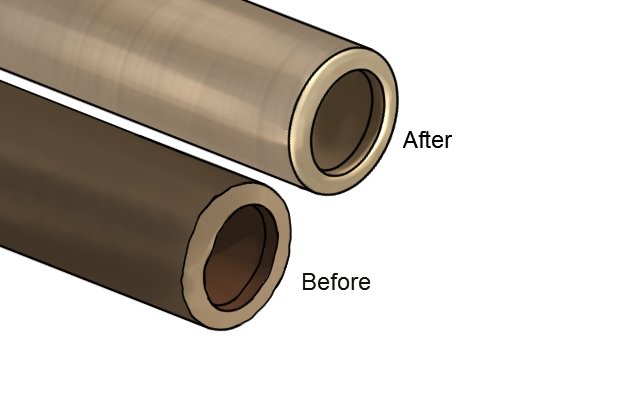

A deburring tool removes burrs from around the edge of a hole or entrance in a workpiece and creates a chamfered edgeFor more information on chamfers, see the section: | |||

|

Deburring tools are used to smooth out the rough edges produced during the manufacturing process. | |||

|

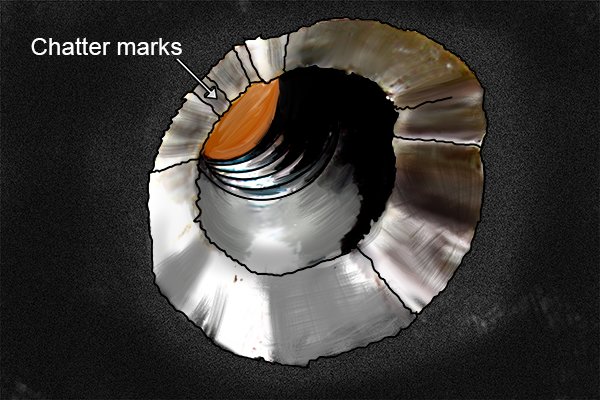

A deburring tool can also be used to remove chatter marks from machining. See our section: What is chatter? | |||

|

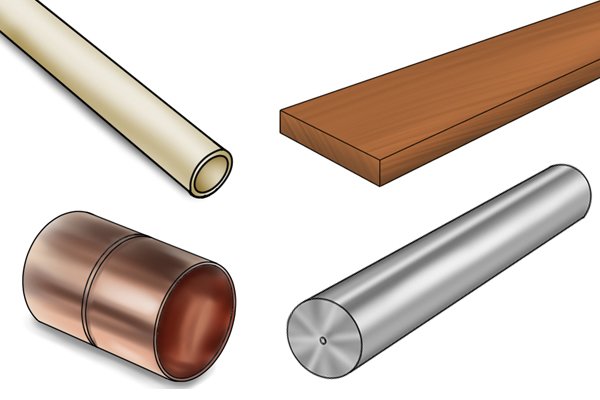

What materials can deburring tools be used on?Deburring tools are designed to be used on plastic, nylon, copper, wood and many other non-metallic materials as well as mild steel, mild cast iron and aluminium. |

|||

|

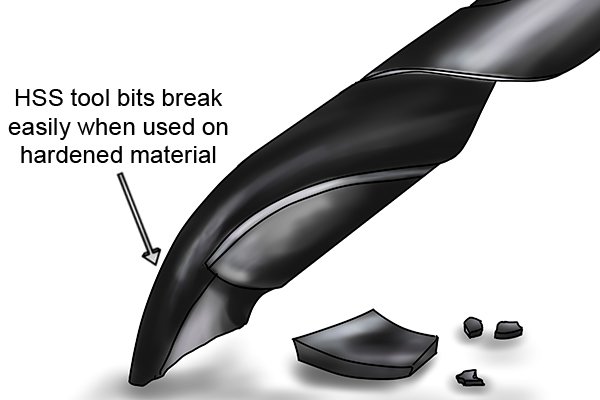

If used on much harder materials (e.g. hardened steel), the deburring tool could chip or break, as the metal you are cutting will be harder than the tool.For information about deburring harder metals, see section: | |||