How to weld caps onto the end of a round or

|

||||

| Shop for Weld Clamp Magnets | ||||

|

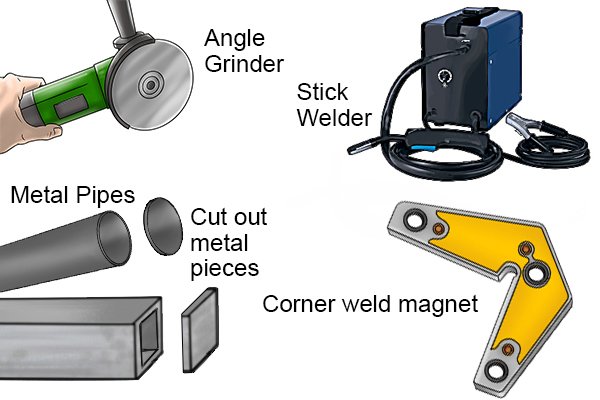

Things you will need:

|

|||

|

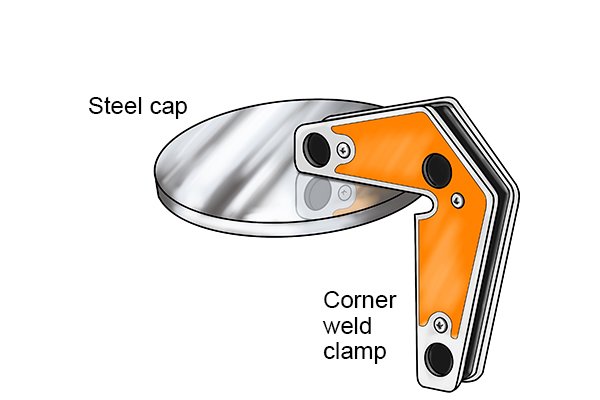

Step 1 – Place magnet on cut metalPlace one flat edge of the magnet down the centre of the cut out piece of metal so that the end of the magnet sticks out beyond the edge. |

|||

|

Step 2 – Line up metal with pipeLine up your cut out piece of metal as perfectly to the inside of the pipe as you can. Place the end of the magnet onto the edge of the pipe so that the cut out material is held flat with the end of the pipe. |

|||

|

Step 3 – Tack weldTack weld at three or four points along the outside conjoined edges of the cut out metal and the pipe. |

|||

|

Step 4 – Remove magnetRemove the magnet from the tack welded pipe and then continue to fully weld the seam of the cap and pipe with your stick welder. |

|||

|

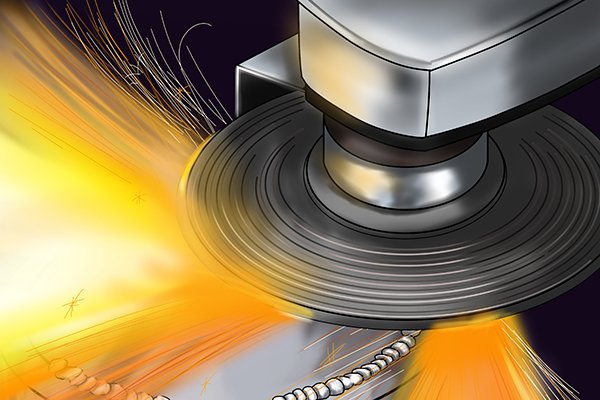

Step 5 – Grind off edgesGrind off the bumpy edges of the weld to give a clean finish. |

|||