Which type of steel should you choose when buying or making a tool?

Most decisions about which steel to use are based on a combination of the following factors:

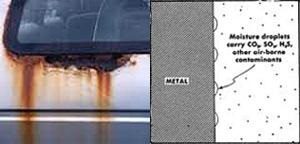

Will it be subjected to corrosive environments?

Atmospheric, concentration of particular chemicals, water, salt water, chloride content and presence of acid – all these, either individually or combined, provide an environment with which to corrode steels.

What operation temperatures will it undergo?

Corrosion rates can be accelerated by high temperatures. Therefore higher grade steels with more resistance to heat deformation have been created to remedy this. Tough austenitic steels are primarily used for low temperature steels.

How strong will it need to be?

Stainless steels, such as austenitic, duplex, martensitic and PH steels offer higher strength while also giving excellent corrosion resistance. Processes such as forming and welding often influence which of these is most suitable. Work hardened, high strength austenitic steels would not be suitable where welding was necessary as the process would soften the steel, for example.

Added strength (even at high temperatures) can be provided from precipitation hardness, a process also known as ‘ageing’ where the steel is heated for long periods of time and cooled down very slowly.

Is the item to be welded?

Ferritic steels are weldable but only in thin sections. Duplex steels are more difficult to weld than austenitic steels but are now regarded as fully weldable. Austenitic steels however, are generally more weldable than the other types. Martensitic and PH grades are less weldable.

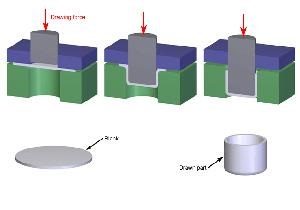

Is forming required to make the component?

Forming requires ‘drawing’ and ‘stretching’ and austenitic steels are the most formable of all of the types. Ferritic steels, in general terms, are not as formable but are still capable of producing intricate shapes. Duplex, martensitic and PH grades are not as formable as the others.

What shape or form is required?

There are a large number of forms and sizes associated with the supply of steel, for example bar, tube or sheet. However, not all grades of steel are available in the same manner. Martensitic steels are more likely to be supplied in bar form, ferritics are more likely to be in sheet form and austenitic steels are supplied in all product forms over a wide range of dimensions.

What are your expectations of the steel's performance?

Factors such as aesthetics (how it looks) can outweigh the structural requirements in some instances so it is important to thrash out any misconceptions from the start through compromise, to ensure that the final product delivers all characteristics expected. This is an important consideration often missed in the selection process.

Availability

The choice of steel for creating the product may not available in the time frame given. Be prepared to investigate alternate, functional types.

Cost

Buying cheaper steel grades which will function just as well as more expensive grades, is not always a sensible approach. For instance, many stainless steel grades can be initially more expensive but can work out cheaper in the long run due to their improved wearability and corrosion resistant properties compared to lower, cheaper grades which do not. These type of decisions are known as ‘Life Cycle Costing’.

Special requirements, such as non-magnetic properties, may also need to be taken into account.

It must also be borne in mind that steel type alone is not the only factor in material selection. Surface finish is just as important in many applications, particularly where there is a strong aesthetic component.

Gathering as much information as possible is a must. Missing information can be the difference between a successful and unsuccessful application.