What are Alloy Steels?

Every steel is considered an alloy since an alloy consists of more than one element (with at least one element being a metal) and steel is a mix of iron and carbon. However, not all steels are called “alloy steels”.

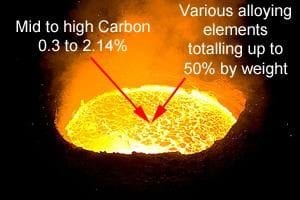

Alloy steel is considered a steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight. These additions improve the steels mechanical properties. The term “alloy steel” is the standard term referring to steels with other alloying elements in addition to the carbon.

Alloy steels, with these various elements added in various quantities, improve the materials ductility, strength, hardenability, temperature resistance, corrosion resistance, toughness and other properties.

Carbon, in various quantities, can be combined with these alloying elements, although carbon content over 2% places the steel into the cast iron category without these additional elements.

How is the alloy strength tested?

There are a vast array of different elements that can be added in various combinations to achieve specific properties.

Depending upon its alloying elements and heat treatment, the ultimate tensile strength of alloy steels can vary from about 80 to 300 kpsi (kilo-pounds per square inch which is equal to 1000psi). This measurement of strength is determined by the point at which the steel tears or ruptures under test.

When an alloy is created, test-pieces from that particular batch are sent to be tested for strength and other properties which are expected of that alloy to possess/endure. Provided the alloy passes these tests/specifications, it is then certified and stamped/ labelled for accurate identification.

Carbon content and other impurities are then reduced and extracted from the molten iron by blasting it with oxygen (hot air).