What are Steel's Properties?

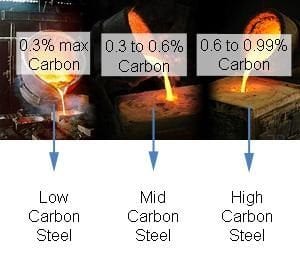

Iron with various proportions of carbon gives low, mid and high carbon steels. When the carbon content exceeds 1%, it is classed as ultra-high carbon steel. The carbon content of these steels is approximately 1.0–2.0% and can be tempered to a great hardness.

Ultra-high carbon steels are used for special, non industrial purposes like; knives, axles, punches and a whole array of various cutting tools.

Note that steels with a carbon content of 2% or more without further added elements are considered to be cast iron.

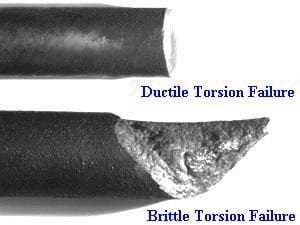

When more carbon is added, the steel becomes harder and stronger but more brittle, reducing ductility and toughness.

Properties of Steel

Other elements are added to the steel to give it different properties or characteristics.

Examples of these are as follows;

Brittleness

Ductility

Strength

Toughness

Corrosion resistance

Impact resistance

Weldability

Brittleness

Brittleness – brittle steels are extremely hard but have low toughness. Brittleness causes steel to fracture or snap when subjected to torsion (load/stress). It breaks without significant deformation (change of shape).

Ductility

Ductility – the steels ability to deform under tensile stress (pulling force applied at each end of the steel structure simultaneously). This is often measured by the material’s ability to be stretched before fracturing/tearing or breaking and is known as plastic deformation.

Strength

Strength – the most common factor when designing or buying a product. Also known as yield strength and is measured in Newtons per millimetre squared (N/mm2).

Toughness

Toughness – the ability to absorb energy and plastically deform without fracturing/breaking. Toughness requires a balance of strength and ductility.

Corrosion Resistance

Corrosion resistance – is the steels ability to resist surface oxidation. Oxidation results in tarnishing and potential rust.

Impact Resistance

Impact resistance – the steels ability to withstand heavy blows before deforming or fracturing/breaking. The impact value of a material can also change with temperature. Generally, at lower temperatures, the impact energy of a material is decreased. The size of the specimen may also affect the impact resistance.

Impact Strength

Impact strength/resistance is a very important factor for steels in some applications. Take an aircraft, as an example. Impact can take place by a bird hitting an aircraft, so the structure has to be able to withstand the impact forces of such an event.

Weldability

Weldability – this is the steels ability to be welded/fused together successfully. Carbon steels over 0.6% carbon content have a lower melting point and become harder to weld than lower carbon steels.

For more information, see the page: What is weldability?