What is Hardness?

Hardness is a term given to describe the measured resistance of a metal to indentation, abrasion, deformation, or machining.

Testing equipment and scales have been produced over time to create standards of hardness for certain types of materials and allow for comparison/measurement. Hardness in steels is commonly measured in Rockwell, Vickers or Brinnell.

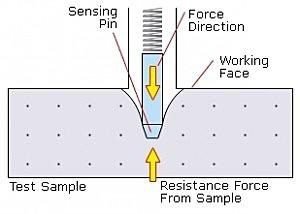

Rockwell is considered to be the most used method of obtaining hardness values of carbon steels, such as silver steel, as it can be achieved in a matter of seconds on a testing machine as shown opposite.

The test-piece is placed between a flat bed (anvil) and an indenter. A wheel is turned by hand which pushes the anvil (and therefore test-piece) upwards against the indenter. This transfers into the hardness reading on the dial/readout.

This force is registered on the dial (or digital readout on more up-to-date models), which indicates the hardness of the test-piece material based on given chart measurements.

For example, a recorded hardness number of HRC 63 signifies a hardness of 63 on the Rockwell C scale. This is typical of silver steel which is hardened towards its maximum state.

Higher values indicate harder materials such as high carbon hardened steel or tungsten carbide. These can have HRC values in excess of 70 HRC.

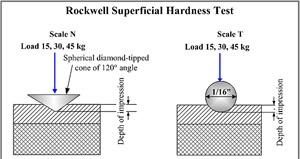

The most common indenter type is a diamond cone ground at 120 degrees for testing hardened steels and carbides. Softer materials are typically tested using tungsten carbide balls ranging in diameters from 1/16 in up to 1/2 in. The combination of indenter and test force make up the Rockwell scale.

Each type of hardness test method has a scale which separates into different catagories (see Rockwell scale chart below). These allow for different test indenters for use on different material grades to establish a more accurate reading.

The regular Rockwell scale uses more Kg (Kilogramme) weight than the superficial scale and therefore makes deeper impressions in the test-piece.

The regular Rockwell scale is used for thicker test-pieces whereas the ‘Superficial Rockwell’ scale is used for thinner test-pieces such as sheet steel.

These combinations make up 30 different scales and are expressed as the actual hardness number followed by the letters HR and then the respective scale.