Introduction to DeWalt Staplers

Staplers, also known as staple guns, are a vital tool for workers in many different industries. Their main function is to drive metal staples into wood, textiles, plastics and many other materials.

They are a mainstay for furniture makers, roofers, flooring and carpet layers, construction workers, upholsterers, insulation installers and electricians, among others. Various sizes are available to suit different applications.

What is a Staple Gun used for?

Pneumatic staplers are heavy-duty air-powered tools which are chiefly designed to join together pieces of wood. They should only be used in places that won’t be visible afterwards, or as a temporary measure to hold surfaces together while glue is setting. Typical tasks may include:

Finishing around windows, doors and edging

Constructing cabinets, chairs, tables, drawers and boxes

Fastening furniture trim

Building staircases

Making picture frames

Fastening flooring

What to look for in a DeWalt Stapler?

Some of the key features to consider when buying a staple gun include:

Source of power

Depth control

Size and weight

Ergonomic grip

Non-marking tip

Adjustable exhaust port

Oil-free operation

Fastener size and type

Source of Power

Driven by compressed air, a pneumatic stapler is faster and more powerful than either an electric or a manual staple gun, and is easier to operate.

You don’t have to go hunting round for a socket as you would with an electric tool, nor do you have to press hard on a lever to fire in each staple, as you would with a manual stapler.

You can simply load up the staples, set the air compressor to the right pressure and start work.

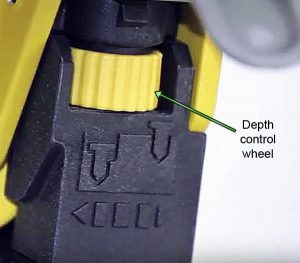

Depth Control

Staple guns with depth control are highly versatile, enabling you to work on many materials of varying thicknesses. You can turn up the air pressure for greater force, so the stapler will be able to drive through knots and high density timber while still stopping at the correct depth.

You can change the drive depth on Dewalt staplers quickly and easily just by turning a thumb wheel to the left (deeper setting) or right (shallower setting), with no tools required. The wheel may be located under the trigger or on the nose of the staple gun, depending on model.

Size and Weight

It’s best to avoid heavy, bulky staple guns if you’re going to be using them for long periods of time. Not only will you get tired, but the accuracy of your work will suffer if the tool is unwieldy.

DeWalt staplers are relatively light and compact, weighing only around 1.3kg, so won’t wear your arm out.

Ergonomic Design

Look for a slim handle, preferably with an overmoulded rubberised grip. This will make the staple gun more comfortable to hold, help absorb vibration and allow you to maintain good control while you work.

Some staplers have rubber bumpers on each side that protect both it and the work surface when you lay the tool down.

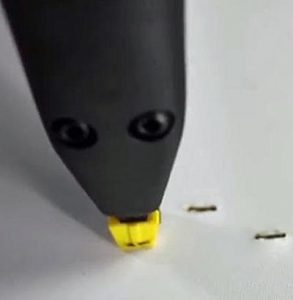

Non-Marring Tip

A soft protective tip that fits over the nose of the staple gun will help you avoid leaving any marks on the work surface.

All DeWalt staplers feature a rubber tip that can be removed and stored on board the tool when not required.

Adjustable Exhaust Port

Some staple guns include a wheel at the top of the housing that allows you to adjust the direction of the exhaust channel.

This feature means you can prevent fumes and debris from blowing into your face without having to change the way you hold the tool. It’s particularly useful when working in dusty or windy conditions.

Oil-Free Operation

Many staplers require you to apply a few drops of pneumatic lubricating oil to the air hose connector before use. Choosing an oil-free staple gun gives you three advantages:

The tool is quick and easy to set up.

There is no risk of excess oil spraying out over the work surface.

Little or no maintenance is required

Fastener Size

Make sure you check which size fasteners you’ll need before buying a staple gun. The bigger the range, the more versatile the tool.

If you have a 12-38mm stapler, for example, you might want to use it with heavy-duty 38mm staples for making furniture, and thinner, shorter 15mm staples for putting together picture frames.

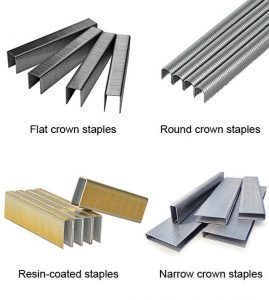

The staple size given refers to the length of the tines (prongs), while the crown measurement describes the width across the top of the staple – which can be narrow or wide, and rounded or flat.

Which staples should you use?

Rounded crown staples are best for use on curved items such as cables and tubing, as they won’t crimp the surface. Flat crown staples are recommended for all-purpose use when attaching one surface to another.

Make sure you match the size of the staple to the task at hand. Heavy-duty staples could ruin delicate window beading for instance, while lightweight ones would struggle to penetrate floorboards or large items of furniture.

Some staples are coated in resin. When the staple is driven into the surface, the resulting friction heats up the resin and turns it into an adhesive, making the fastening extra secure. Once in place, these staples are extremely difficult to remove – so don’t use them as temporary fixings.

If the staples are going to be exposed to the weather, look for galvanised (zinc-coated) ones which won’t corrode.

Combination Staplers

Combination, or combi, staplers are able to drive nails and tacks as well as staples, making them very versatile. These tools are also known as 2-in-1, 3-in-1 or 4-in-1 staple guns, depending on how many different types of fastening they can accept.

The most common combination of fastening is brad nails and staples (2-in-1). Brad nails are small, thin fasteners that are used for lightweight finishing work because they can be driven right in below the surface to become virtually invisible.

Staple Gun Safety

A pneumatic stapler is a powerful machine, so treat it with respect and always follow the manufacturer’s instructions for its use and care.

A few safety tips:

Never point the staple gun at yourself or anybody else.

Never squeeze the trigger unless the tip of the stapler is pointing towards the workpiece.

Never pull the trigger or press the trip mechanism while loading the tool.

To avoid accidental firing, always detach the air supply when the stapler is not in use, as well as when making any adjustments, clearing a jam, cleaning the tool or moving to another work area.