Introduction to DeWalt Impact Wrenches

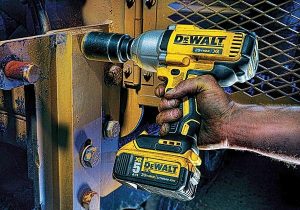

Impact wrenches are the power tool you turn to when nothing else will shift that stubborn rusted-in bolt or wheel nut. With the aid of attached sockets, you can use them to install or remove large fastenings much more speedily and with far less effort than would ever be possible using hand tools.

They are vital in the field of vehicle repair, where they are used for tasks such as fitting and removing wheel nuts, engine components and suspension bolts. They also play a part in factory assembly lines, heavy machinery maintenance and repair, and construction projects.

What's the difference between an Impact Wrench and an Impact Driver?

Both impact drivers and wrenches are high-torque power tools which operate using a hammer and anvil mechanism to deliver short, sharp bursts of rotational force to overcome resistance.

However, whereas impact drivers are fitted with bits for driving screws and drilling holes, impact wrenches are used with sockets to tighten and loosen large bolts and nuts.

Both tools produce a huge amounts of torque, but wrenches are particularly powerful. Some can deliver over 900Nm of torque, which is more than four times the level of many impact drivers.

How is an Impact Wrench powered?

Impact wrenches for heavy industrial use are often driven by compressed air (also known as pneumatic impact wrenches). They can deliver a lot of force but lack flexibility, as they have to be connected to an air supply.

Electric impact wrenches are much more common, and are available in both corded and cordless versions.

The advent of lightweight yet powerful Lithium-Ion batteries has made cordless models increasingly popular, as they are straightforward to operate and can be used anywhere.

What to look for in an Impact Wrench?

The main features to consider when buying an impact wrench include:

Torque

Speed

Size and weight

Anvil type (socket holder)

Hand grip

Build quality

Work light

Brushless or brushed motor

Corded or cordless

Torque

Torque is the turning force of the tool. More demanding tasks, such as working with rusted-in wheel nuts or particularly large bolts, will require higher levels of torque.

Impact wrenches can produce anywhere between 200Nm and 950Nm of torque, depending on model.

Speed

The driver’s power is measured in IPM (Impacts Per Minute), referring to how many times the hammer strikes the anvil. Most impact wrenches deliver well over 2,000 IPM.

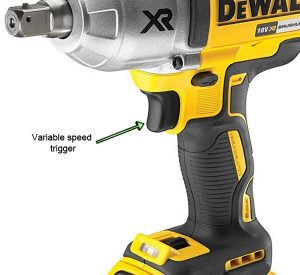

The tool is operated using the speed control trigger. Squeezing the trigger starts the anvil turning. The further you pull the trigger in, the more torque will be delivered, and the faster the anvil will rotate. Conversely, slackening your grip will slow the wrench down, which is preferable when working with small or brittle fasteners. Releasing the trigger completely will bring the tool to a halt.

Some impact wrenches have gears that provide a choice of three speed settings, giving you greater control over the amount of speed and torque produced. This will allow you to work with more precision and so reduce the risk of damage to the bolt or socket.

Even if your wrench doesn’t have gears you will still be able to maintain a good level of control over the tool using the parabolic speed trigger, which is very sensitive to pressure.

Size and Weight

Impact wrenches can vary considerably in size and weight. Obviously the more powerful versions have bigger motors, so are larger and heavier.

A compact model is more suitable for home, workshop and garage use, allowing you to work in confined spaces and reach above your head if necessary.

Anvil Type

The anvil sits at the tip of the impact wrench and is the part where you attach the socket or adaptor.

There are two types of anvil:

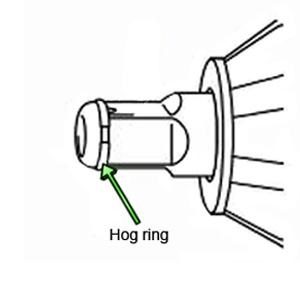

Hog or friction ring – best for mechanics and for anyone else who needs to change sockets frequently.

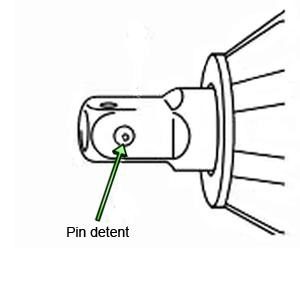

Detent pin – best for industrial use where one attachment tends to be used for long periods, and where strong socket retention is vital.

Hog Ring Anvil

A hog ring, also known as a friction ring, consists of a metal clip which fits over a rubber O-ring on the top of the anvil. The clip compresses when you push the socket on, then applies pressure to grip the inside of the socket and prevent it from falling off.

The main advantage of a hog ring is its ease of use. No tools are needed to change sockets – you just push the accessory into place, then pull it off with your fingers when you’ve finished. This makes it ideal for mechanics, who may need to use many different sizes of socket in the course of a working day. DIY home owners will also appreciate the simplicity of this system.

Detent Pin Anvil

This type of anvil features a small raised pin which holds the socket in place. To attach a socket you have to line up the hole in the side of the socket with the detent pin, press the pin down using a nail, small screwdriver or Allen key, then slide the socket over the pin on to the anvil. When you release the pin it will engage in the hole and hold the socket tight.

This method is more secure than a hog ring but also more fiddly and time-consuming. It is most suitable for construction and manufacturing workers who may be using the same socket for long periods of time and won’t require frequent changes.

Hand Grip

A soft rubberised handle makes the tool comfortable to hold for long stretches, as well as helping you to maintain a firm grip – a particularly important feature if you’re likely to get water, engine oil or grease on your hands. The rubber compound will also help to absorb noise and vibration.

Durable Build

A strong yet lightweight aluminium or magnesium gear case combined with all-steel gears will provide long tool life and efficient power transmission.

The main housing of a DeWalt impact wrench is made of hard-wearing, heavy-duty plastic, while the handle is protected by a rubberised compound.

Work Lights

Good visibility will help the quality and accuracy of your work, so sufficient lighting is important. Compact DeWalt impact wrenches have three LED lights surrounding the nose, giving shadow-free illumination in even the darkest of corners. Larger wrenches have an LED on the foot instead, to ensure that the light won’t be blocked if bigger sockets are used.

Brushless or Brushed Motor?

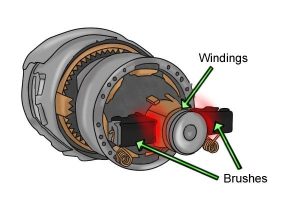

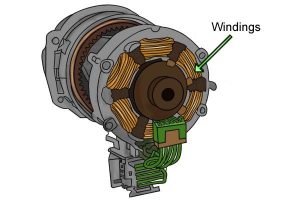

A brushless motor offers great run-time and performance, but what is it? Both brushed and brushless motors operate using an electro-magnetic field with a current flowing through it.

A brushed motor (pictured) uses carbon brushes to deliver current to the motor windings (copper coil) situated directly on the rotating shaft. This creates friction, which causes the brushes to eventually wear out.

In a brushless motor (pictured) the windings are wrapped around the outer, stationary part of the motor. Magnetic sensors are used instead of direct contact with the rotating shaft, so no brushes are needed.

Friction, heat and noise are greatly reduced, resulting in a cooler, quieter and more efficient motor. The tool can be made lighter and more compact, as no brush housing is required.

An impact wrench with a brushless motor will usually cost more than one with brushes, but is quieter and more efficient because the motor will adjust its power according to the task at hand, saving battery life.

And as there are no brushes to wear out, the motor will last much longer, with maintenance kept to a minimum.

However, if you’re only going to use the wrench for occasional DIY the brushes might never need replacing anyway, so you may decide that a lower specification, less expensive brushed model would suffice.

Corded or Cordless?

A corded impact wrench performs just as well as a cordless version, but some users find the power cable a little awkward in tight spaces. However, this type has two advantages:

A corded impact wrench costs considerably less than a battery-powered model of equivalent specification.

You can simply plug the tool in and get to work straight away, without having to wait for batteries to charge.

A cordless impact wrench is often preferred by mechanics, maintenance engineers and other professionals who frequently have to work in confined spaces. Its advantages are:

You’re not reliant on a constant supply of electricity. Once you’ve charged the battery the tool will run all day, so it won’t matter if there’s no power source at the job site.

With no trailing cord to worry about, you can work faster and more freely.