Tips On Torque Control

All cordless drill drivers deliver torque (turning force), but only some have a feature called torque control (also known as an adjustable clutch), which if used correctly, prevents the tool from delivering too much force at one time when driving screws.

You only need torque control for screws. In drill mode, the driver will automatically produce its maximum level of torque. This is because drilling holes requires a lot of power, so you don’t need to control the amount of torque, as you would when inserting screws.

How Does Torque Control Work?

When inserting screws the drill driver will encounter resistance, making it harder to drive the screw in. Enough torque must be delivered to overcome this resistance and insert the screw to the correct depth.

DeWalt drill drivers have an adjustable control ring with up to 15 settings (depending on the model) which allows you to pre-set a maximum level of torque for your task.

Once that level is reached, the clutch will disengage the drive shaft and stop the chuck and screwdriver bit from turning.

When torque control kicks in, the motor inside is still turning but the chuck and screwdriver bit have been stopped, so the screw can’t be driven any further in.

If the screw hasn’t been fully inserted when the drill driver stops, then you know a higher level of torque is needed.

What Are The Benefits Of Torque Control?

Once you have used torque control this question will really answer itself. However, if you have not used a power drill with torque control yet then this section explains all of the benefits of torque control!

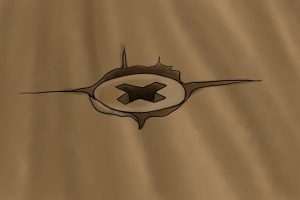

Prevents Damage to Screw Heads

If enough resistance is met, the screw will not be able to turn any further into the material. However, the screwdriver bit will continue to rotate and could damage the screw head.

If the correct torque level is selected, the screwdriver bit will stop turning when enough resistance is met, and prevent this happening.

Stops Screws Being Driven Too Far In

Too much torque will drive the screw below the surface of the workpiece, rather than to the correct depth. You also risk losing control of the drill driver and damaging the work surface.

Gives Consistent Results

By using the torque control setting you can make sure that every screw or hole is driven to exactly the same depth, rather than relying on look and feel. This consistency will improve both the appearance and strength of the product.

Allows Multiple Working

As long as the torque settings are synchronized, more than one person can work on the same product at different times yet drive the screws in to precisely the same level. And on a big project such as a building site, many drill drivers can be used by a large number of workers to achieve identical results.

What Level Of Torque Do You Need?

The amount of torque required will depend on a number of factors:

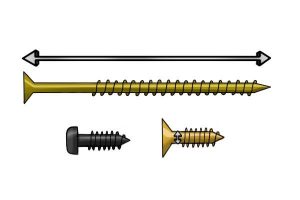

Screw diameter and length – a screw with a long, thick shank will need more torque than a shorter, thinner one.

Type of material – drilling into tough materials such as metals and hardwoods will require more torque than softwoods or plastics.

Pilot hole – if you drill a pilot hole first, you’ll need less torque to insert the screw.

How to Adjust Torque Control?

Step 1 - Release Trigger

Release the speed control trigger and wait for the drill driver to come to a complete stop.

Step 2 - Rotate Torque Ring

Locate the arrow on the top of the tool and rotate the numbered torque ring until the torque level you require is aligned with the arrow.

If in doubt, always start with a low level of torque and gradually increase if the driver struggles to turn the screw.

Safety First

Be careful when handling power tools! Never try to move the torque adjustment ring while the spindle is still turning, or you could damage the drill driver as well as yourself.