What are moulding bars made of? |

||||

| Moulding bars may be manufactured from a number of alloys, including: | ||||

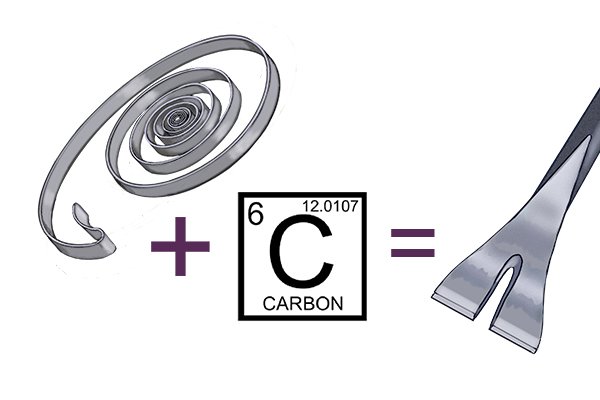

High carbon steel |

||||

|

High carbon steel is an alloy which contains a higher percentage of carbon, and is capable of being heat-treated during tool manufacture. | |||

Spring steel |

||||

|

Spring steel is a type of steel which can be easily reformed after deformation (such as bending), enhancing the longevity of the bar. Bars manufactured from spring steel are not suitable for very heavy duty work, due to the metal’s propensity to bend. | |||

Alloy steel |

||||

|

Alloy steel can mean a number of different steel alloys, but usually refers to a carbon steel alloy; this can contain any percentage of steel.

Steels containing higher percentages of carbon are able to be heat-treated for enhanced durability, whereas steels containing a lower carbon percentage will be more malleable (easy to bend). |

|||

|

You might also find moulding bars in combinations of the above – for example, ‘high carbon spring steel’, which uses a higher percentage of carbon to counter the malleability of spring steel, while retaining its durability. | |||

|

Which material you choose should depend on what tasks you will be using the bar for.

For example, for heavy duty tasks, you should choose a high carbon steel moulding bar, unlikely to bend or break under the strain. For light work, where ease of use is the primary consideration, spring steel is likely to be the best choice for you. |

|||

|

For more detailed information on material properties, see our section: What are bars made of? | |||