What are the parts of a through hole

|

||||

|

||||

Magnet |

||||

|

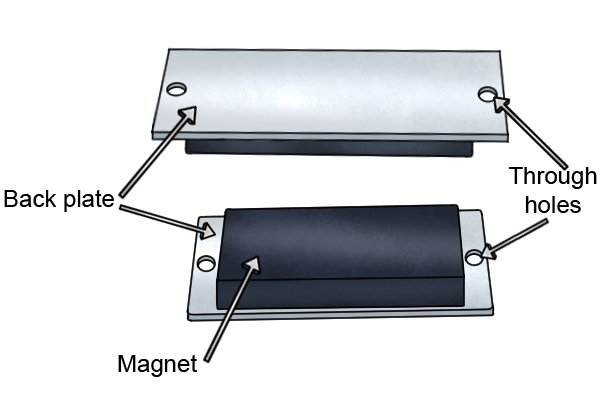

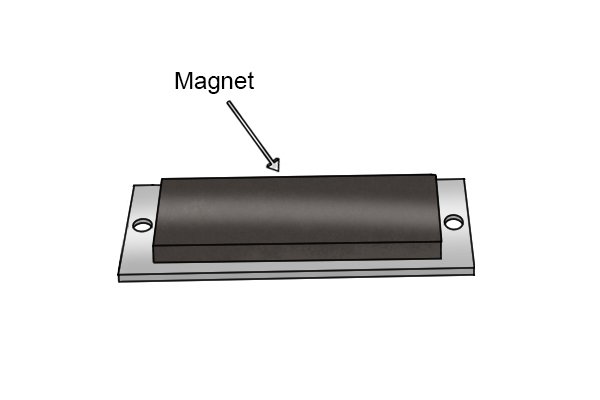

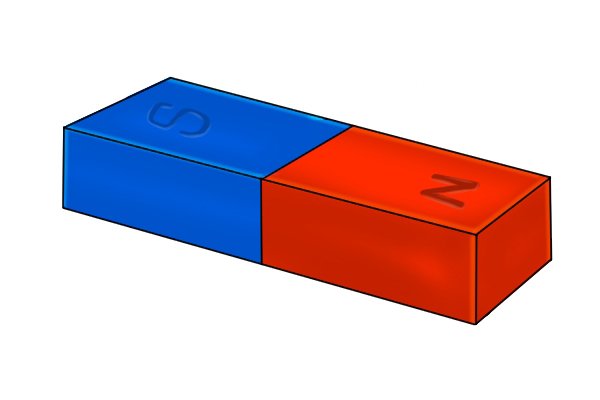

A through hole magnetic mounting pad has one large rectangular bar magnet on its base.

For more information on bar magnets, see What is a bar magnet? |

|||

|

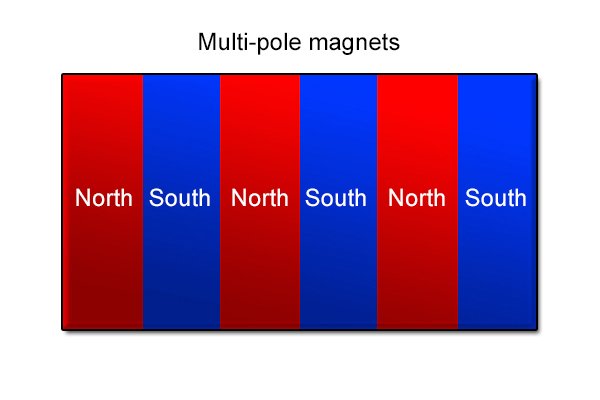

This magnet has only one magnetic face, magnetised in the form of a multi-pole magnet. This is where the magnetic face is magnetised in a striped pattern of alternating north and south poles e.g. north, south, north, south. | |||

|

The through hole magnetic mounting pad requires multi-pole magnetisation due to the steel back plate preventing the magnetic field from escaping through the top of the magnetic mounting pad. Only one half the magnetic mounting pad needs to be magnitised so that it can attach to a ferromagnetic material. The other side is used to hold the sign with the help of the through holes. | |||

|

||||

|

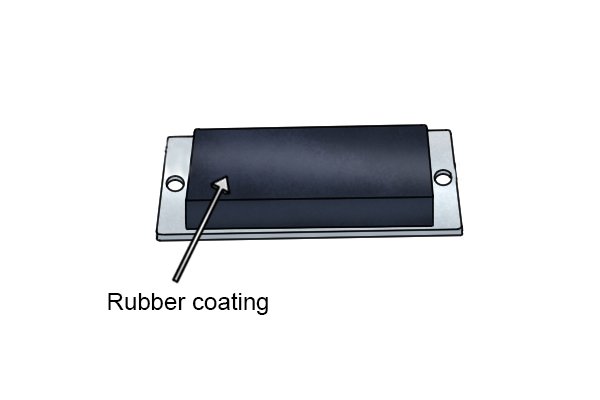

Rubber coatingThe magnet on a through hole magnetic mounting pad has a rubber coating to prevent it from scratching the non-ferromagnetic material it is attached to. It also increases the amount of surface friction. |

|||

|

The increased surface friction helps the magnet to grip the surface of the non-ferromagnetic material. This means it can hold larger objects than a standard magnet, such as a bar magnet. | |||

|

The rubber used on the magnetic mounting pad is made of polyurethane, which is a type of polymer plastic.

For more information on polyurethane coatings, see What types of casing can a magnet have? |

|||

|

The rubber coating can become indented and torn. When the magnet’s rubber coating becomes torn after a few years due to general wear and tear from outdoor exposure e.g. freezing conditions, the rubber will become very brittle. | |||

|

You can remove it with a pair of scissors and re-coat the magnet with some new rubber. | |||

Back plate |

||||

|

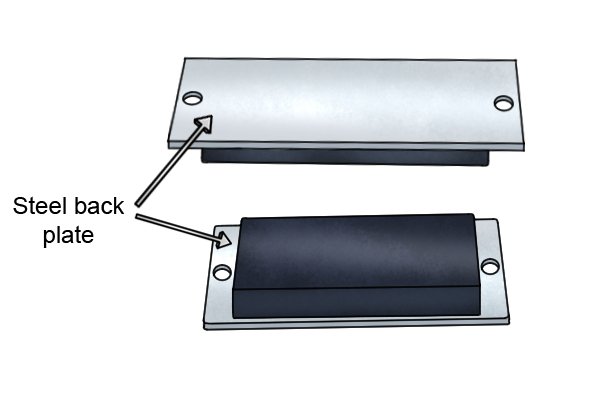

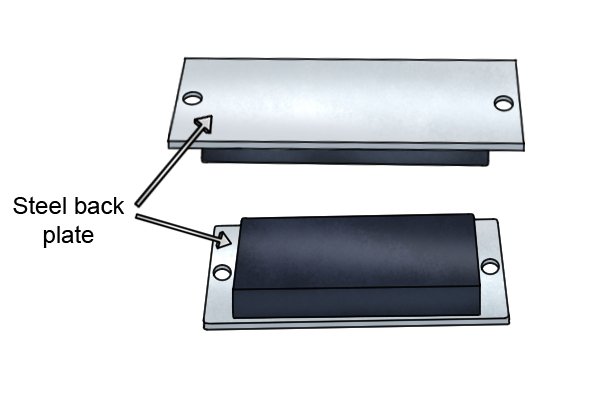

The back plate is attached to one of the long magnetic faces of the magnet and helps to attach the magnet to a non-ferromagnetic material. The back plate is used as a barrier between the non-ferromagnetic material and the magnet. It protects the magnet from any adverse effects from the non-ferromagnetic material it is attached to such as any bumps or scrapes which could affect the magnet’s magnetic capabilities. | |||

|

The back plate on a through hole magnetic mounting pad is made from steel which has been coated in zinc.

As magnetic mounting pads are predominantly used outdoors, the zinc coating provides corrosion resistance, whilst the steel gives the magnet added strength. |

|||

Through holes |

||||

|

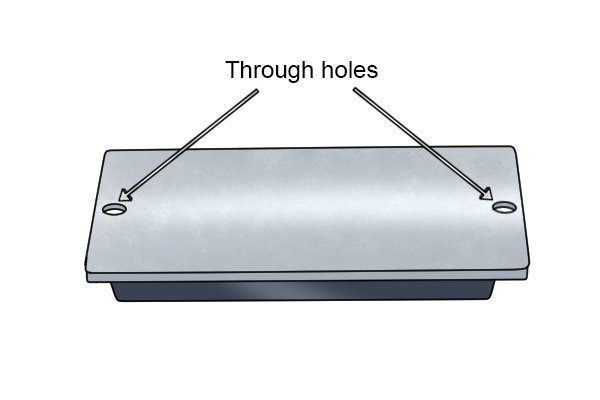

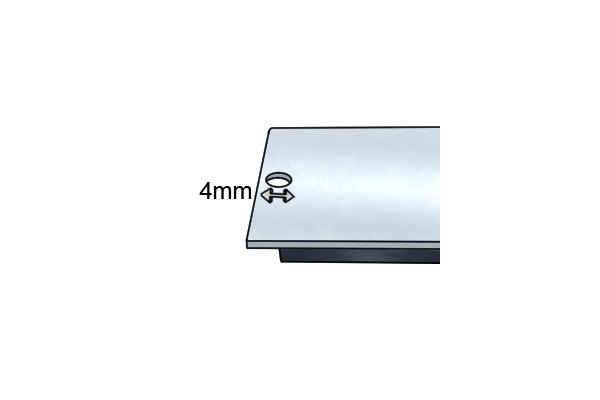

A through hole is a type of hole which has been drilled through completely (from one side of the material to the other). In this case, the through holes are on the magnet’s back plate. | |||

|

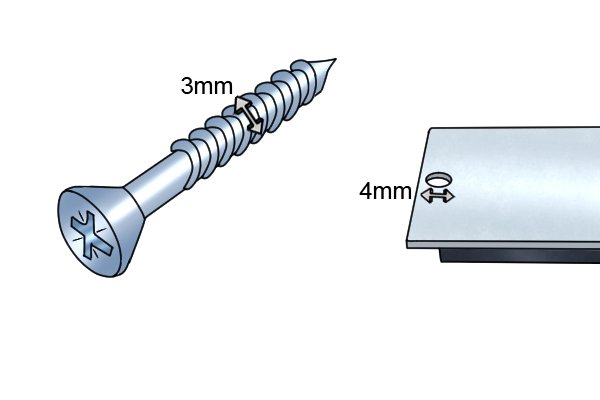

The through holes are used to attach the through hole magnetic mounting pads to a non-ferromagnetic surface, e.g. a plastic roof car sign, with the aid of two screws.

For more information on how to do this, see How to use a through hole magnetic mounting pad? |

|||

|

The through holes are described as being either D4 or D5, this means that the through holes are either 4mm (0.16″) or 5mm (0.2″) in diameter. | |||