How to install a coiled threaded insert?

| Shop for Threaded Inserts | ||||

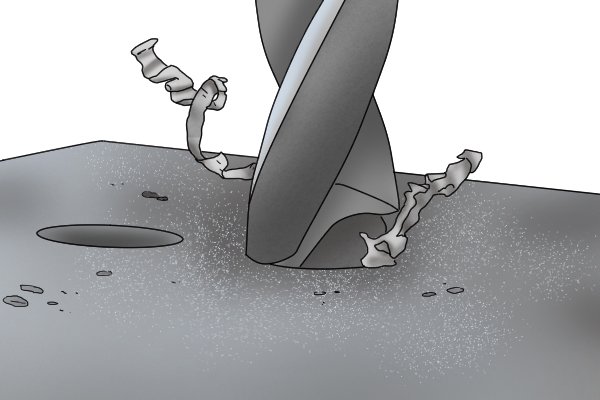

Drilling |

||||

|

Step 1 – Clear damaged threadsInsert the correct size drill bit into a drill and clear the damaged threads. Some specialised spark plug coiled insert kits will include a specialised tap which does not require drilling beforehand. |

|||

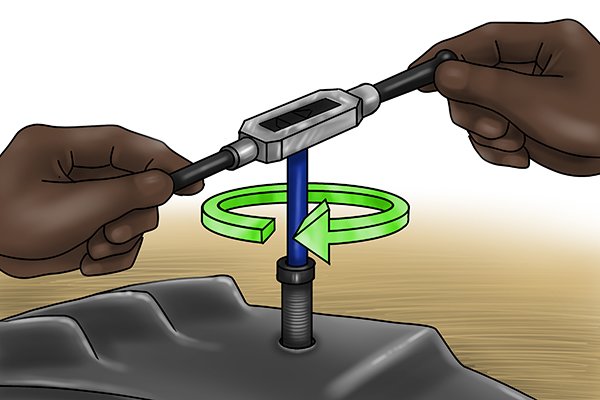

Tapping |

||||

|

Step 2 – Rotate STI tap into holeRotate the STI tap into the hole using either a tap wrench, suitable installation tool or spanner. It is often recommended to use a suitable lubricant during this process. The tap is rotated clockwise, but may occasionally require a quarter turn backwards to free the debris and ensure a smooth completion. |

|||

|

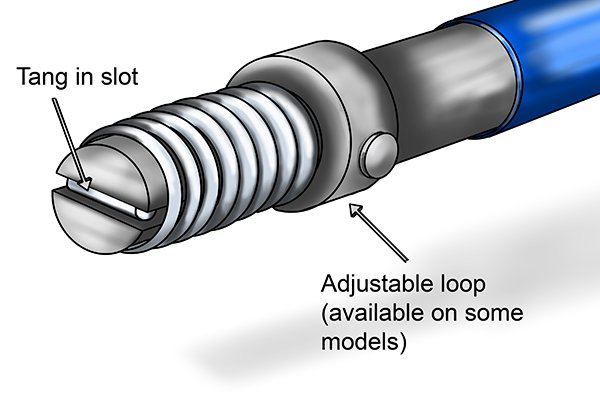

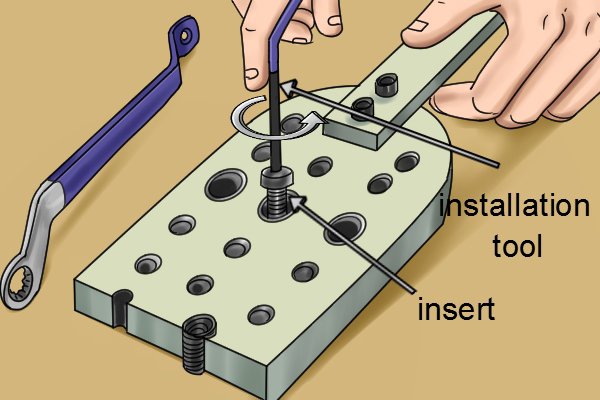

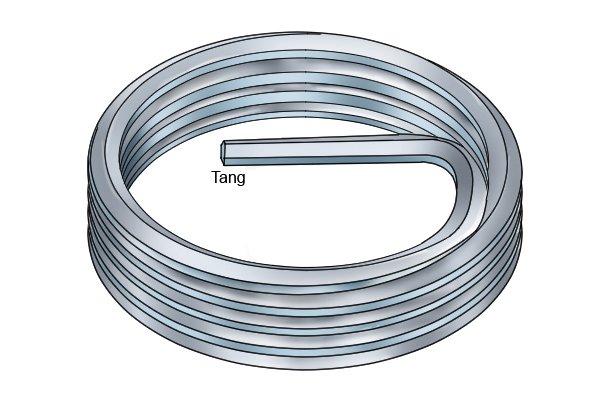

Step 3 – Choose optionFor slot-on installation tools…….the insert should be placed on to the tool (tang upwards) and then the tang should be rotated so it falls into the slot. If available, an adjustable loop can be moved to line up the insert. |

|||

|

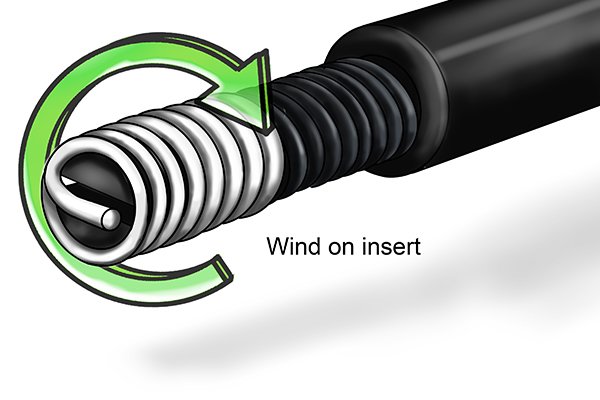

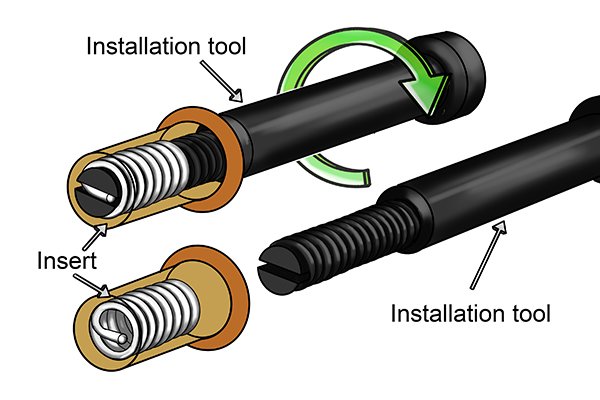

For thread-on installation tools….…the insert should be wound onto the tool (tang upwards). There is often a catch at the end of thread-on installation tools which catches the tang and secures the insert in place for threading. |

|||

Installation |

||||

|

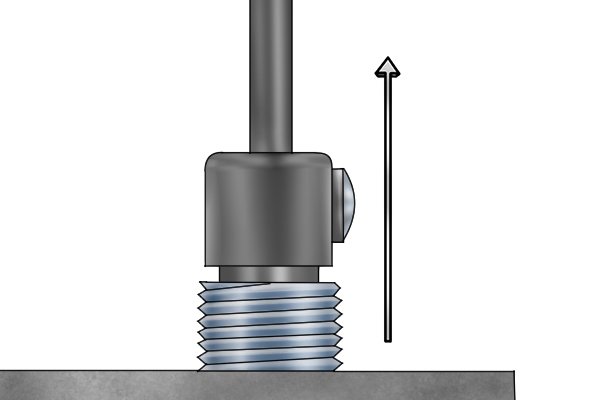

Step 4 – Install insertTo install the insert, place the installation tool with insert at the mouth of the newly tapped hole. Rotate the tool in a clockwise direction until the insert begins to take, then continue the rotation with a slight pressure until the insert is half a turn below the surface. |

|||

|

Step 5 – Choose optionOption 1:To remove the slot-on installation tool…simply pull out. Do not rotate the tool anti-clockwise as this may cause the tang to break off prematurely. |

|||

|

Option 2:To remove the thread-on installation tool, rotate anti-clockwise until the tool is free. The insert remains in the hole because the spring shape means that the insert can expand into the hole once the tang is free of the catch. |

|||

Tang removal |

||||

|

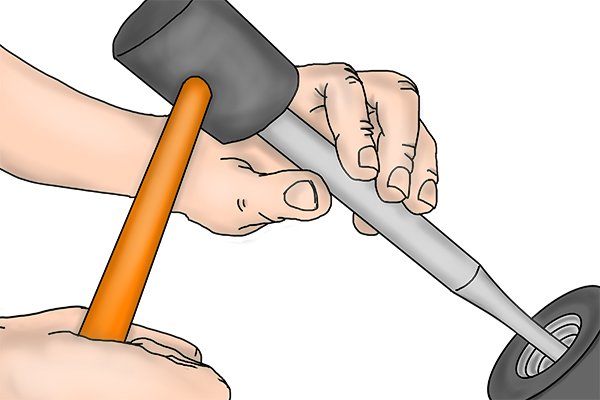

Step 6 – Remove tangUse the tang removal tool, a screwdriver, or a similar long, thin object to snap off the tang. Simply place in the hole and apply a short burst of pressure until it snaps. |

|||

|

If it is an open screw hole, like the one pictured above, the tang simply falls away. However, a bottomed screw hole requires the tang to be either left in place, snapped and left loose in the hole or removed from the hole. The tang should only be left on if the insert meets the bottom of the hole. Removing the tang may require the use of a vacuum, compressed air or magnet. | |||