What are nail pullers made of? |

||||

| Shop for Nail Pullers | ||||

|

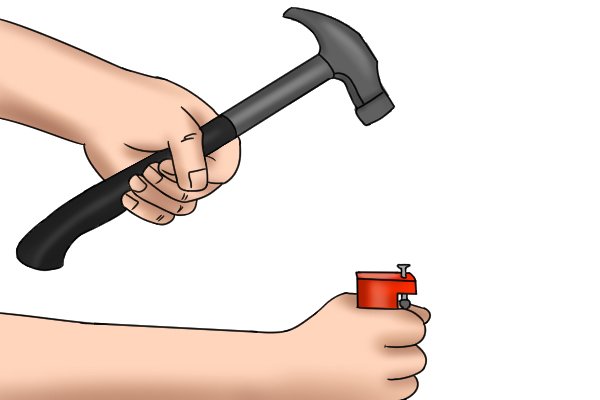

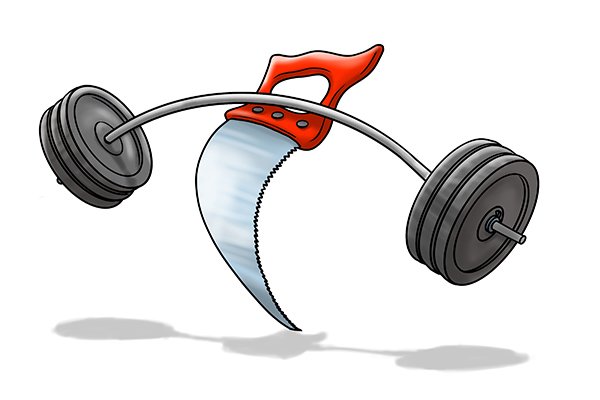

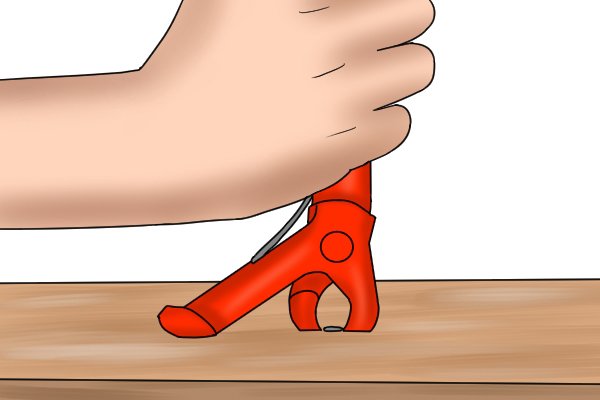

One of the main requirements for the materials used to make a nail puller is that they are strong and durable. This is because the tool is put through quite a lot of bashing as it is hit in place over the nail head and also needs to have the strength to lever the nail out. | |||

|

Usually nail pullers will be made with malleable cast iron, steel or steel alloy. These are all alloys of iron and carbon and materials which are known for their strength. | |||

|

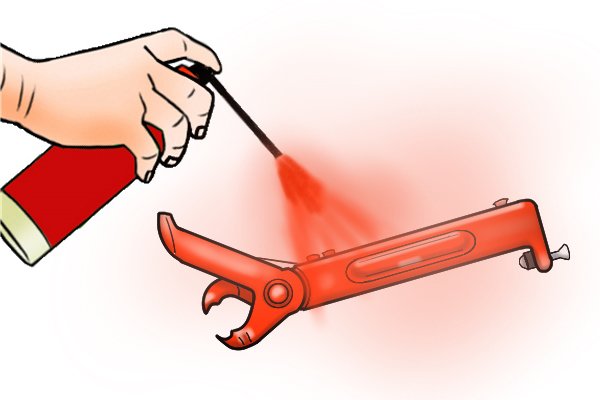

Nail pullers will have had their parts painted, lacquered, coated or treated to help prevent wear and corrosion of the tool, because iron and steel are both susceptible to corrosion. | |||

Hinged jaws |

||||

|

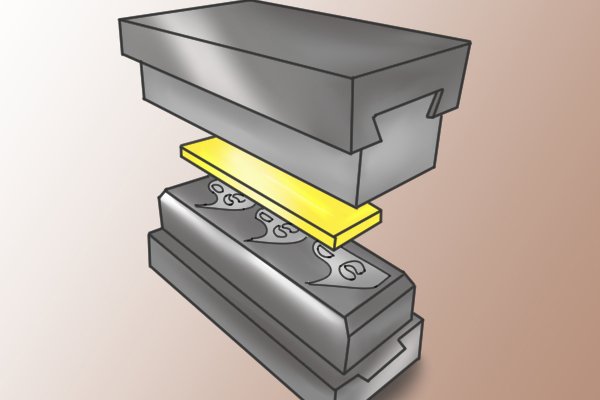

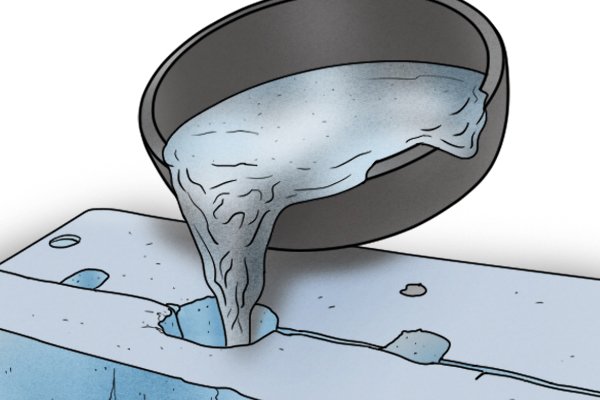

The jaws will usually be made out of drop-forged iron or steel, iron will usually be stronger than steel but slightly more brittle.Drop-forging is a process of forging metals into precise shapes by knocking them down into a mould with a mechanical hammer. In the case of the nail puller, this helps to ensure the jaws are sharp so they can dig into wood and effectively remove nails. | |||

|

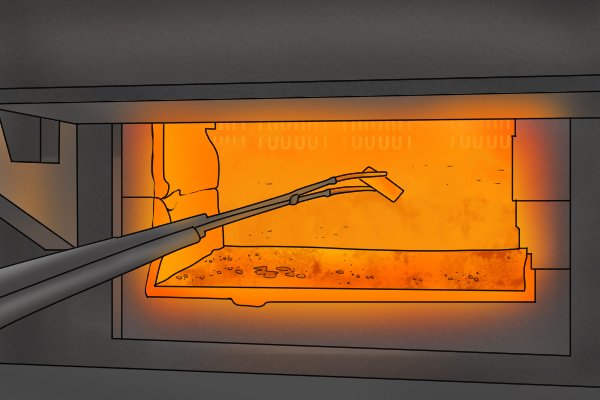

You will also find that, usually, the jaws will have been heat treated to strengthen the material further. Heat treatment provides the jaws with the toughness they need to penetrate wood and the strength they need to grip the pull. | |||

Pivot point |

||||

|

The pivot point, or fulcrum, is part of one of the jaws, so this will be made of the same material as the jaws, which is usually iron or steel. | |||

Sliding handle |

||||

|

If the nail puller has a moving or sliding handle, this works as a built-in hammer, often called an integral hammer or rammer. The handle is usually made of steel or malleable cast iron, which are strong and tough. | |||

Striking area |

||||

|

Nail pullers that don’t have a handle will have a tough, flat end.This is usually made from hardened steel, so it can withstand a hammer blow, and will often have some kind of anti-corrosion treatment. | |||

|

On this striking area there will be two parts to use with the claw hammer. These will either be forged on and part of the area or they will be steel pins. | |||

What’s the difference between malleable cast iron and steel? |

||||

|

Cast iron and steel are alloys of iron, being iron mixed with carbon and possibly other substances, such as sulphur or manganese.The main chemical difference is that malleable cast iron will contain around 2.0-2.9% carbon while steels will have a carbon content of less than 2.1%. The higher the carbon content, the tougher the material is but the more brittle it is. | |||

|

Both steel and iron are often used for hand tools. Different grades of these alloys will be used, depending on the application and the quality of the tool. Tools which use higher quality alloys will usually be more expensive. Both have advantages and disadvantages, so which is best will depend on its application and the user’s budget. | |||

|

Malleable cast ironHas high strength, heat-resistance, toughness and also has some give, so it can be shaped fairly easily without it breaking. This gives it wider applications than other irons, and means it is sometimes used to replace carbon steel. |

|||

|

Malleable cast iron has a limit to how large a part it can produce, therefore it is common for it to be used for small castings which need to be strong but have some flexibility, such as with hand tools, electrical fittings and machine parts. You will find that the handles of some nail pullers are made of malleable cast iron as they are fairly slim parts which need to be tough and have a little bit of flexibility when hitting the jaws into wood. | |||

|

Malleable cast iron has a better casting performance that cast steel, which is why you may find that the handle may be made of cast iron but the jaws could be drop-forged steel. Drop-forging parts gives you more precision than casting. | |||

|

The production process for malleable cast iron is quite complex and therefore production is more expensive than that for normal grey cast iron or cast steel. | |||

|

SteelSteel is generally a more popular choice for tools today, although you will find differences in the types of steel that are used. Usually, you will see that the parts of nail pullers are made from alloy steel or hardened steel because it is strong, tough and versatile. |

|||

|

However, compared to malleable cast iron, cast steel has less wear resistance and mobility and cannot be shaped in the casting process as accurately as malleable cast iron.This is why steel parts of nail pullers are often drop-forged rather than cast, however drop-forging steel is more expensive than casting it. | |||

|

Alloy steelAlloy steel refers to steel which also contains carbon and other elements, in varying amounts. This will change its mechanical properties, this change will be controlled to ensure it is suitable for its specific purpose. For nail pullers the alloy needs to be strong and tough with a bit of flexibility so it can take the force of being hit into wood. |

|||

|

Because the chemical composition of steel can be controlled and adapted for different purposes, it offers greater variability and flexibility for different designs. Steel can be used to cast small and large pieces, up to hundreds of tons. | |||

|

Hardened steelHardened steel usually refers to high, or medium, carbon steel which has been specially hardened. The higher the carbon content is in steel, the harder and stronger it becomes, however this reduces its ability to be shaped easily and makes it more brittle. The jaws on nails pullers are usually made of hardened steel so they are tough enough to penetrate wood. |

|||

|

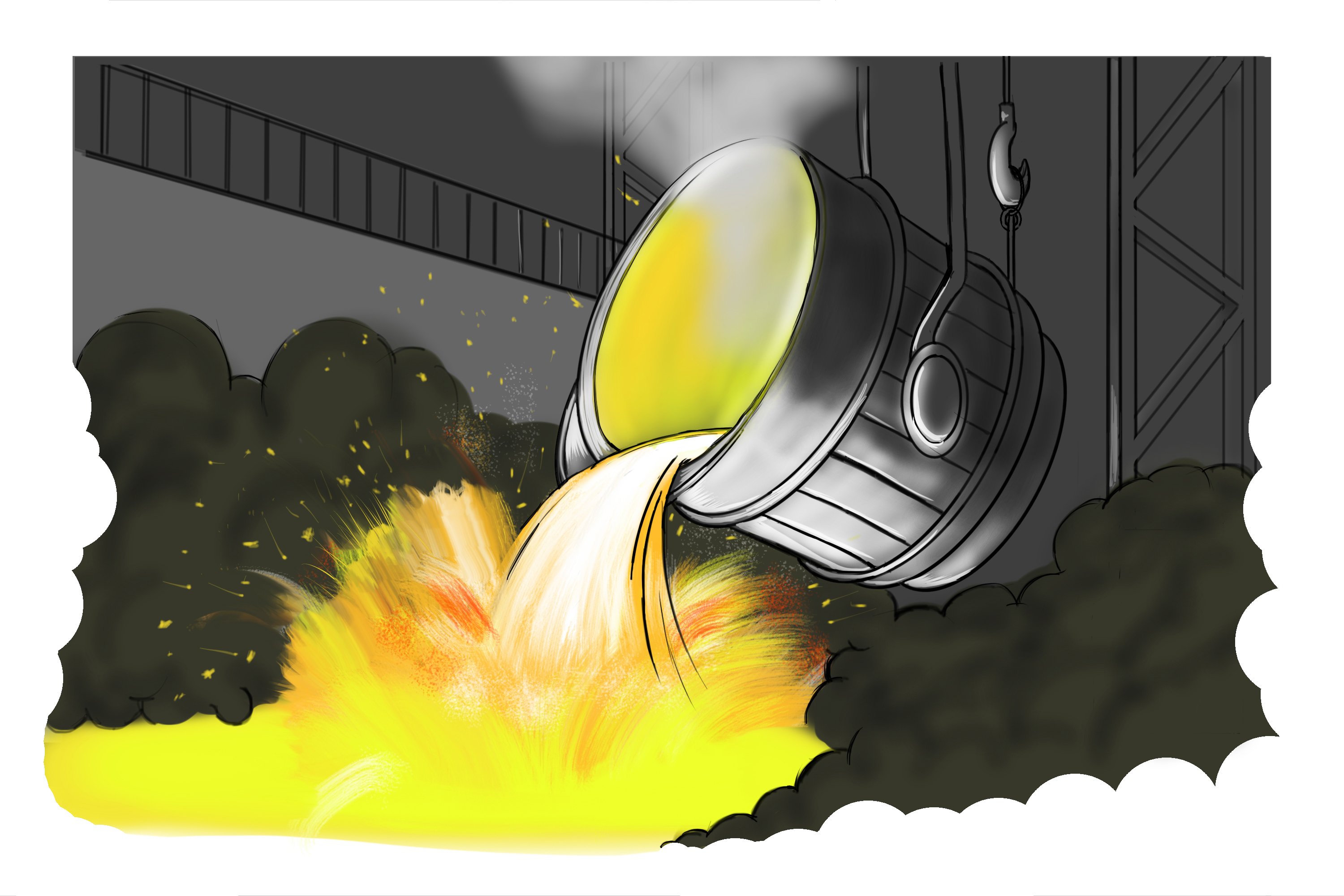

To harden steel further, it can be put through heat treated, a process where it is heated to a certain temperature and then cooled rapidly with water, oil or an unreactive gas. This is known as tempering and quenching. | |||

|

Which is best?The quality of different steels and irons is difficult to assess easily – different alloys produce metals with diverse properties. A good indicator of the quality of the metal will usually be the reputation of the brand that made it and the cost of the tool. |

|||

|

Iron can be forged into smaller, and therefore more precise shapes, it is very tough, but can be brittle and is usually slightly more expensive than standard tool steels.Forged steel is likely to be cheaper, and nearly as tough as iron, but will not produce small parts as accurately as iron. Alloy and hardened steel will gain more strength than standard steels, making it stronger than iron, but they will become more brittle and more expensive. | |||