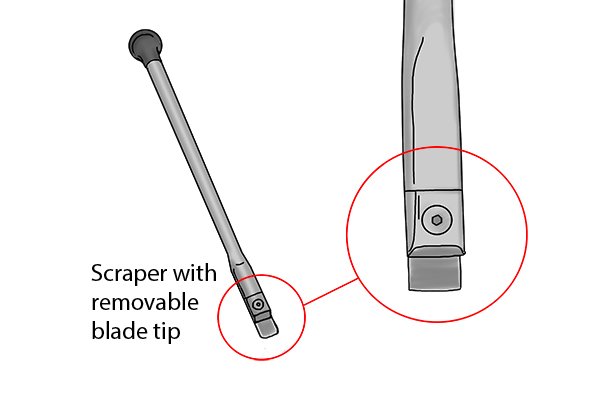

What is a removable scraper blade? |

||||

| Shop for Engineer’s Scrapers | ||||

|

There are several advantages to having a scraper with removable, easily replaceable blades.

As it takes less time to change a blade than sharpen one, a replaceable blade enables you to complete all of your scraping and then sharpen the blade at another time. This is particularly useful if you’re scraping a workpiece away from your workshop and don’t have a grinding disc available to sharpen blades. |

|||

What are replacement scraper blades made of? |

||||

|

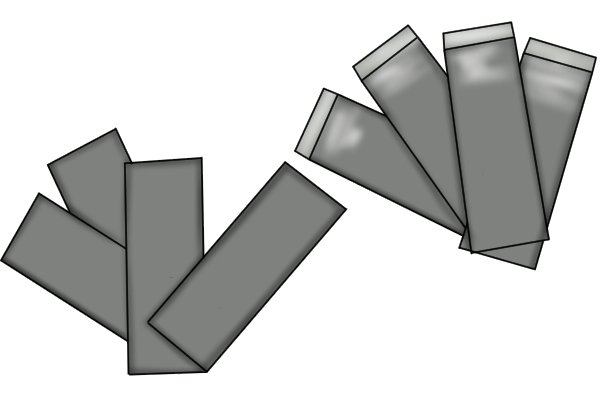

Replacement scraper blades are made from one of two types of material: carbide or high speed steel (HSS).

Carbide, or tungsten carbide to give its full name, is much harder than HSS, so blades made of it can last up to ten times as long before they need sharpening.

The two main disadvantages of carbide scraper blades are that they can only be sharpened with a diamond grinding disc wheel, and cost more than HSS blades. |

|||

How are scraper blades fitted to the shaft? |

||||

|

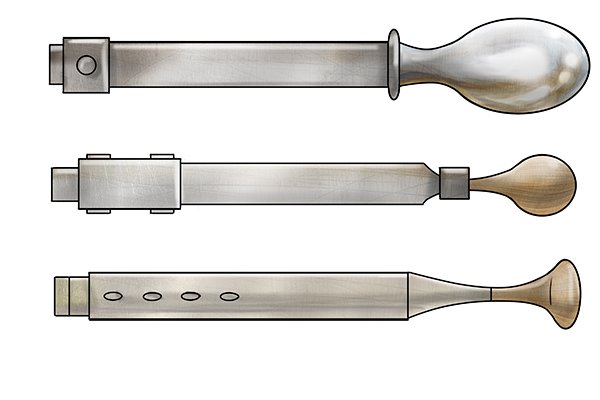

There are several ways that scraper blades can be fitted to the shaft of a scraper. Different manufacturers use different methods, but the three main ways are:

|

|||