Introduction to DeWalt Sanders

Sanders are hand-held power tools which greatly speed up the process of smoothing surfaces. They are mostly used on wood, but some types can also tackle other materials including plaster, metal and plastic. With the right kind of attachments you can use them to smooth, shape and polish wood, remove excess material from a workpiece, and get rid of rust from metal surfaces.

As sanding tends to create a lot of debris, we recommend fitting a dust extraction system to any sanders which do not come with their own dust bag. Wearing a protective mask is also advisable.

What are the different types of Sander?

There are several different designs of powered sander available to suit a variety of tasks:

Random orbit sander

Belt sander

Sheet orbital or finishing sander

Detail sander

Random Orbit Sander

Also known as a random orbital sander, this is regarded as the most versatile type, so makes a good all-round choice. It is widely used by cabinet makers, carpenters and DIY fans alike. If you’re only going to get one sander, this would probably be the best bet.

It works by means of an attached sanding disc which rotates at high speed while simultaneously travelling in an elliptical, or irregular, orbit. This ensures that no part of the disc moves along the same path twice, virtually eliminating the risk of leaving behind swirl marks – a common problem with normal orbital sanders, which don’t vary their pattern of rotation.

Belt Sander

Large and powerful, a belt sander is a bit of a blunt instrument. It’s intended for heavy-duty work on large flat surfaces such as floors and stairs where speed, rather than finesse, is the main requirement.

It works by means of a loop, or belt, of sandpaper that rotates around rollers at each end of the tool. Belts are available in different widths, with the most common being 75mm and 100mm. Most sanders of this type feature automatic belt tracking which will centre the belt for you – usually with a manual override option.

A belt sander isn’t suitable for small or curved areas, which are better tackled with a detail or palm sander.

Compact Belt Sander

The compact version of DeWalt’s full-size sander features a narrower belt and a palm grip for light-duty work smoothing smaller surfaces including handrails, windowsills and door jambs. One side has a flush design, so the tool can get right up to the edge of walls, door frames and other vertical surfaces.

You can use it one-handed or add a second handle at the front when you need extra control for tricky tasks.

Sheet Orbital or Finishing Sander

A sheet orbital sander, also known as a finishing or block sander, is used with a square or rectangular sheet of sandpaper attached to a vibrating pad which moves in tiny circles, or orbits.

Designed for rounding off sharp edges and smoothing down wooden surfaces before applying a final coat of paint or varnish, this type of sander is lightweight and easy to operate with one hand. However, it is not suitable for heavy-duty tasks.

Square orbital sanding machines are sometimes referred to as ¼ sheet sanders because they can be used with a quarter of a sheet of standard sandpaper. Some models have a piercing plate that lets you turn a sheet of regular sandpaper into one with holes punched in the right places.

Rectangular orbital sanders are also known as ⅓ sheet or ½ sheet sanders for the same reason. Their straight edges make it possible to get into corners where a round pad wouldn’t fit.

Detail Sander

A detail sander has a triangular base plate to enable it to penetrate tight spaces that a random orbital sander wouldn’t be able to reach (due to its circular base). It is ideal for small fiddly tasks requiring a high degree of precision. Suitable uses include sanding furniture, shelves, cabinets, door trim and mouldings.

How to choose a DeWalt Sander?

Some sanders are kept simple, others offer a whole host of bells and whistles. Features to look out for include:

Variable speed control

Orbit size

Handle design

Dust control

Lock-on switch

Variable Speed Control

A sander’s speed is determined by the length of the sanding strokes. For some orbital models, the speed varies between 3,000 and 6000 orbits per minute. Others can produce up to 12,000 orbits per minute, halving the stroke length. Shorter strokes result in a glossier surface.

Being able to adjust the speed while you work gives you greater control and makes the tool more versatile, allowing you to easily switch between coarse sanding and fine finish projects. You can use a slow setting for fiddly tasks or when working on soft wood such as pine or cedar, and a faster one for removing large amounts of material in a hurry.

Orbit Size

The orbit size refers to the diameter of the base plate’s rotation. Wider orbits (4-6mm) allow you to remove excess material more quickly, while smaller orbits (1-3mm) are preferable for a finer, shinier finish.

Some machines have two orbit size settings – for instance, the DeWalt D26410 dual-orbit sander has the option of 6mm for fast material removal, and 3mm for fine finishing.

Handle Design

The right kind of handle is obviously important for maximum comfort and control over the tool. The majority of random-orbit sanders have a single-handed palm grip, but some may have a barrel shaped or D-shaped handle. The best handles feature a rubberised overlay to minimise vibration and provide insulation from heat generated by the motor.

Many sanders have a second handle at the front which can be removed when not in use. Palm grip models often have a rubberised body grip as well – a useful feature whenever you need to use both hands for extra precision.

Dust Control

The process of sanding creates a lot of dust – a power tool’s worst enemy. Look for a sander with sealed bearings and switches to protect the motor. It will run more efficiently and last much longer.

Sanders usually have a dust bag, extractor port or both. Dust collection has several benefits. It serves to reduce the amount of harmful particles in the air, and will also prevent layers of wood dust gathering between the sandpaper and the workpiece. The extra air flow across the surface of the sandpaper will also help stop excess heat building up on the pad (which could otherwise melt the plastic hooks on hook-and-loop fastenings).

Even if your sander comes with a dust bag, you can still attach an external extractor hose if you prefer. This is generally considered a more convenient option for large jobs generating a lot of dust.

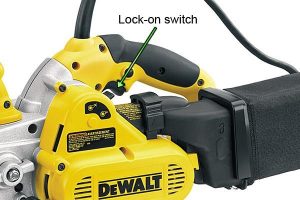

Lock-On Switch

The larger sanding machines can be quite tiring to use for long periods. A lock-on button will ease hand and wrist fatigue by locking the machine in the ‘on’ position so you don’t have to keep holding down the trigger. This feature is most commonly found on belt sanders.

Which sandpaper should you use?

Various types of sandpaper, sanding mesh and discs are on the market. Sheet orbital sanders accept ¼, ⅓ or ½ sheets of sandpaper which are secured by clamps to the base plate. Some models include a nylon hook-and-loop pad as an additional option for quicker sheet changes.

Sanding belts are attached by a clamping lever, and have to be centred on the roller before use. Most have an automatic tracking option. Random orbit sanders normally use the hook-and-loop fastening method.

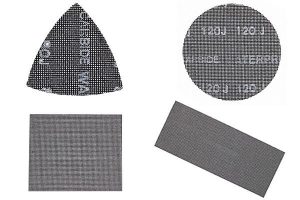

Random orbit sanders and detail sanders use round and triangular sanding discs respectively. The discs include pre-punched holes which line up with apertures in the base plate to facilitate dust removal during use.

Orbital sanders also have dust-extraction holes in their bases. They accept square or rectangular sanding media, available either as whole sheets or in packs of pre-cut, pre-punched paper.

Whole sheets have the advantage of being cost-effective and widely available. However, they are less convenient than pre-cut ones as they need to be cut to size and pierced with a hole punch that corresponds to the pattern on the base plate of the sander.

Grit Sizes

Sandpaper is classed by its grit size, which generally ranges from 40g (coarse) to 240g (fine). Choosing the right size for the job is vital to avoid damaging the workpiece.

The largest grit sizes, such as 40 and 60 grit, are suitable for extensive, rough sanding tasks where you need to remove a lot of material.

Medium grit sizes (80g and 120g) are used to achieve a smooth surface and sand away imperfections.

Finer grit sizes such as 180 or 240 are intended for extra-fine sanding to remove any faint scratches and prepare the surface before staining, painting or polishing.

What is sandpaper made of?

Most sanding sheets and discs consist of a paper backing covered in abrasive aluminium oxide grains which are held together by resin. The bigger the grains, the coarser the sandpaper.

DeWalt also produces a range of tough woven metal mesh sheets which last around four times longer than conventional ones. They won’t easily clog up with dust and debris – and if they do, you can wash them under the tap and put them back in the sander.