Introduction to DeWalt Routers

Routers are highly versatile power tools used by joiners, woodworkers, cabinet makers and DIY enthusiasts. With a router you can create intricate designs in wood, plastics, fibre board and some metals. You can also hollow out grooves, create decorative mouldings, shape edges and make joints, among other things. Like a drill, a router uses bits (also called cutters) to bore into the material.

A router is compact enough to be guided easily over a workpiece or carried around a job site. There is also the option to mount it upside down in a router table for repetitive tasks, or when working on small items which would otherwise be hard to anchor securely.

For small radius workpieces, shaping edges and creating chamfers a laminate trimmer can be a handy tool. Similar to a fixed base router, its small size and low weight make it ideal for precise, single-handed use.

What are the different types of DeWalt Router?

There are two main types of router:

Fixed base router – the base is rigid, and is attached to the body of the router to form a single unit.

Plunge router – the base is spring-loaded, allowing the upper body of the router (holding the bit) to be pushed down into the material.

Fixed Base Router

Fixed base routers are suitable for moulding designs and edge cuts that need a high degree of precision in a straight line. As they can’t be plunged into the workpiece from above, they can only start cutting from the edge.

The depth of cut has to be set before use, and can’t be adjusted once the machine is running. These tools are usually smaller, lighter, more affordable and simpler to use than plunge routers. They also work well when attached to a router table.

Plunge Router

Plunge routers are able to begin the cut in the middle of the workpiece if required. The upper body of the tool, holding the bit, is pushed downwards over two spring-loaded columns which guide the path of the bit, enabling it to bore into the surface from above. This greatly increases the variety of cuts you can make.

Unlike the fixed base version, plunge routers allow you to adjust the cutting depth while the motor is running. And with the help of a locking feature, you can also use them to shape the edge of the workpiece in the same way as a fixed base router. Plunge routers are probably the most popular and versatile type on the market today.

Combination Router

A combination router consists of the top part of the router (the motor and collet) together with a removable or interchangeable base, giving you the best of both worlds.

With a twist of the motor housing, you can remove the plunge base to use the router for detailed shaping, carving, grinding and sharpening tasks. Various different bases can be used for specialist applications.

What to look for in a DeWalt Router?

Some of the main features to look for when selecting a router include:

Size and weight

Speed

Depth control

Dust control

Size and Weight

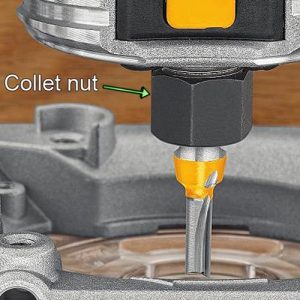

A router’s size is defined by its collet (the steel sleeve holding the bit in place), which usually measures between 6mm and 12mm.

If space is an issue, a compact 6-8mm fixed base router is ideal for trimming all grades of wood, plastics and aluminium. This size will fit comfortably in your palm so you can use it one-handed if necessary.

Heavy-duty applications – working on dense hardwoods, for example – are likely to require a router with a 12mm collet that can hold larger cutters.

Weight is another factor to consider. A small, lightweight machine is easily manoeuvred for intricate work, and will be less tiring to use for long periods.

Speed

The most versatile routers offer a variable speed control dial, which lets you reduce or increase the rate at which the router turns the bit. This is particularly handy if you need to use a variety of cutters and work with different types of material, as you can fine-tune the cutting speed to avoid damaging the workpiece.

Single speed cutters are not usually suitable for use with aluminium and plastics because these materials need to be worked on at slower speeds to cut effectively. However, heavy-duty single speed routers are ideal for powering swiftly through hardwoods.

Electronic speed control is another useful feature. This makes sure that the speed you select is maintained under any conditions to give a consistent finish every time.

Depth Stop

The depth stop is an important feature which is used to determine the height of the bit and, therefore, the depth of the cut. This setting can then be locked into place so you can cut accurately to the same level every time.

The depth scale will show you how deep the cut is going to be in relation to the base. In the case of plunge routers, the depth stop acts as a guide to prevent the router from being lowered too far into the material.

Dust Control

Routing can create a lot of dust, so it’s worth giving priority to machines that can be used with dust extraction systems. This improves visibility as well as air quality. Most routers include a spout that can be attached to a hose to divert harmful particles away from you.

The DeWalt DW621 goes one step further, with an extraction feature that doesn’t require a hose. The dust is sucked up through the column and blown out of the chimney on top, which you can attach to a specialist vacuum.

Routing Hints and Tips

Choose the correct cutter for the task. Using the right router bit will not only produce better results but will keep the cutter sharp for longer.

For instance, a high-speed steel bit is best suited to non-abrasive materials, so using it on a thick plywood board will soon make it go blunt. Always ensure you turn off and unplug your router before inserting or changing bits.

Make sure the bit is fully secured in the collet, and if it’s a variable speed router check that it’s set to the correct speed before switching on.

Connect up a dust extraction system if you have one, to avoid breathing in harmful particles.

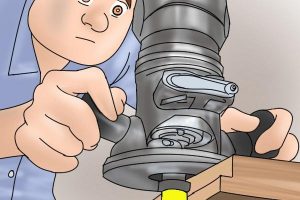

If you’re routing by hand, grasp the handles firmly and maintain a secure grip. Don’t hold them too tightly – you need enough grip to guide the router effectively, but not so much that it becomes tiring.

If you’re table routing you should use push tools when working on small items, while larger pieces can usually be fed by hand.

Grip the push tools firmly and try to apply even, constant pressure from behind the workpiece as well as from the side.

Aim for a consistent feed rate and be alert for problems which may occur at certain places. Corners can be tricky because they are areas where users tend to slow down their feed rate. Mentally prepare yourself before you reach these points, and try maintain a smooth, gliding movement.

Whether you are routing on a table or by hand, the process should always feel relatively effortless. If you ever find yourself forcing the material past the cutter, or vice versa, then your technique needs improvement.

Listen to the sound of the motor while you work. You can usually pick up any early signs of router problems by the sound it’s making, and can also tell whether you are feeding at the right rate.

When approaching the end of a cut, it’s all too easy to unintentionally speed up and rush the cut. This can lead to a rough or uneven edge, so try to keep your movement smooth and consistent right to the end of each pass. Wait until the router bit has completely stopped turning before removing the tool from the workpiece.

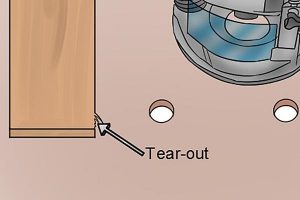

How to avoid Tear-Out?

Tear-out can happen when the fibres that are being routed are left unsupported. Although this can occur during any routing task, it is particularly common when making an irregularly shaped or curved item.

Tear-out is most likely to happen when routing along the edge grain or end grain of a workpiece. However, there are a number of steps you can take to reduce or prevent it.

Always use sharp router bits. Blunt bits will grab and pull at the material instead of cutting cleanly through it, leaving a rough finish and increasing the likelihood of tear-out.

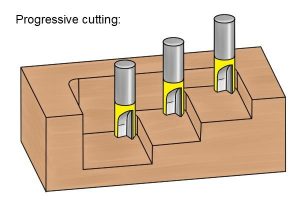

You should also cut progressively. Trying to remove too much material in one go is another common cause of tear-out. When making a deep cut, gradually remove small quantities of stock in a series of shallow passes. Aim to remove about 3mm of wood with each pass until you reach the required depth.

Try to follow the direction of the wood grain wherever possible. This will help you to make a smoother cut. If you rout against the grain, the wood fibres may catch on the bit and break apart to create tear-out.

If you are working on every edge of the workpiece, we recommend you rout the end grain first so that you can then get rid of any tear-out when routing the adjacent edges.

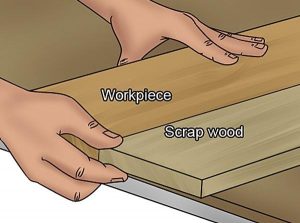

When the router bit reaches a corner of the workpiece it will often snag on the grain of the wood, causing tear-out. Clamping a spare block of wood on to the end of your work will support the edge of the workpiece and help prevent its wood fibres from breaking.

If you’re making a straight cut using a table-mounted router, a zero-clearance fence will give good support to your workpiece and reduce the likelihood of tear-out. As the material moves past the router bit it will be bolstered straight away by the out-feed side of the fence, making tear-out less likely.