Introduction to DeWalt SDS-Plus Drills

What does SDS-Plus mean?

It is thought that the acronym SDS originates from the German ‘Steck, Dreh, Sitz’ (meaning ‘insert, twist, stay’), although for ease of international marketing, manufacturers prefer to call it either Special Direct System or Slotted Drive System.

The updated version is known as SDS-Plus, also written as SDS+. The two types are compatible, so if you have any SDS bits lying around you can still use them in an SDS-Plus drill.

How are SDS+ Drills different to standard drills?

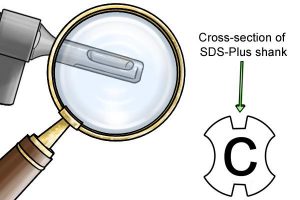

SDS+ drills are much more powerful than conventional drills and have stronger, more sophisticated chucks. There is no bit-holder – instead, the shank of the bit is pushed straight into a specially designed matching chuck, where it fits so exactly that no tightening is required and there is no slippage.

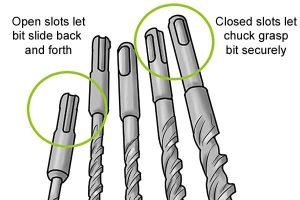

SDS-Plus bits each have four slots along their sides – two that open to the end of the shank, and two that are closed off. The closed slots are gripped by the chuck to retain the bit in the drill.

The two open slots in the shank allow the bit be propelled back and forth like a piston, its path smoothed by two ball bearings inside each slot. This magnifies the hammer action so that power can be directed more precisely and efficiently.

Standard drills are much less effective at delivering concentrated energy because the whole chuck has to move backwards and forwards instead of just the bit.

What types of SDS+ Drill are available?

There are three different types of SDS-Plus drill currently on the market, offering different features and price points:

Two-mode

Three-mode

Three-mode with removable chuck

Two-Mode SDS+ Drills

SDS+ drills with two modes offer a choice between a rotary action (for drilling into wood and metal) and a rotary with hammer action (for drilling into tougher materials such as masonry and concrete). They are generally the most cost-effective type.

Three-Mode SDS+ Drills

SDS+ drills with three modes provide the options of rotary action, rotary with hammer, and hammer action only.

In hammer only mode – also called rotary stop – the drill bit doesn’t rotate but just moves up and down. It allows you to add a chisel attachment for jobs such as chipping off mortar, removing tiles or breaking up thin concrete.

Three-Mode SDS+ Drills with Removable Chuck

These drills offer the same options as three-mode versions, but have the added bonus of a removable chuck. This means you can quickly change the SDS-Plus chuck for a normal one that will accept standard drill bits, making the tool more versatile. However, you can’t employ the hammer action when using normal bits.

Why buy an SDS-Plus Drill?

Power

Even a compact SDS+ drill can tackle a huge range of tasks, whether in the home or on a building site.

There is no need to lean on the drill – with only minimum effort on your part it can breeze through concrete, brick and steel, thanks to a powerful motor (up to 1,000 watts, depending on model) and super-efficient hammering action.

Speed

An SDS-Plus drill can create large holes much faster than a conventional one so you’ll be able to work more quickly – and for most people, time is money.

However, these drills are designed for heavy-duty drilling on hard materials and are not renowned for their finesse. If you need a tool for precision work on soft materials, consider a compact drill driver.

Versatility

With the right accessories you can use an SDS-Plus drill for a huge variety of tasks, including:

Drilling in a wide range of materials including wood, metal, ceramics and masonry

Chipping off mortar, plaster and concrete

Channelling (making cable runs in walls)

Guiding cables through walls

Drilling square holes for electric sockets

Breaking up concrete and masonry

Removing tiles

Ease Of Use

Because only the bit is moving back and forth instead of the whole chuck, the piston-like hammering action of an SDS+ drill causes much less vibration, making it comfortable to use for long periods.

And there is a clutch that cuts the motor if the drill jams, so any sudden twisting or jarring will be reduced.

In addition, some upper range DeWalt SDS-Plus drills include a feature called Active Vibration Control which, as the name suggests, further reduces shaking, making the tool more comfortable to use.

The vibration control is achieved with the use of a special ‘floating’ flexible rubber handle containing shock absorbers.

Value

SDS-Plus drills used to be much more expensive than standard ones because the complex chuck design made them costlier to manufacture.

However, they’ve become so popular that far more are being made, bringing down production costs and putting them within reach of DIY enthusiasts as well as a wider range of professionals.

Is there any difference between SDS and SDS-Plus Drills?

The SDS-Plus as it is also known, is an improved version of the original SDS drill, which is no longer made. The bits are fully compatible, so if you have any SDS bits you can still use them in an SDS-Plus drill.

What's the difference between SDS-Plus and SDS Max Drills?

People often mix up the two, but SDS Max drills are much larger than SDS-Plus machines and have bigger, differently shaped bits. Used mainly by professional contractors, they are designed for extremely heavy-duty work. See Introduction to SDS Max Drills to find out more.