How are spade bits manufactured? |

||||

|

As spade bits are less complicated in design than most other bits, their manufacturing process is much simpler. | |||

|

The end of the cylindrical steel blank is heated and drop forged into a flat spade shape. The process of drop forging involves a heavy piece of metal, such as a power hammer, stamping steel into a mould while it is hot, and so this method is particularly well suited to creating the spade bit’s flat head. | |||

|

The lips, spurs and centre points are then sharpened on a grinding wheel. | |||

|

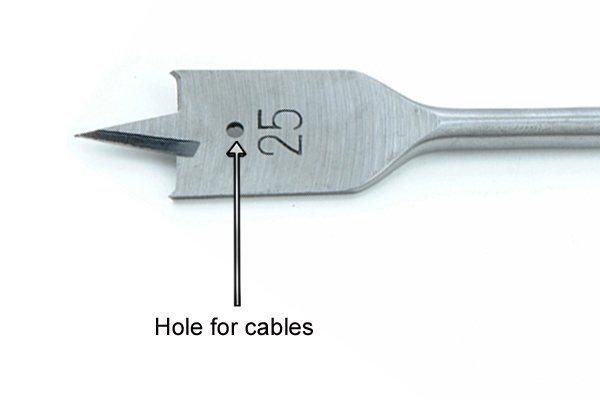

In some bits, a hole is drilled behind the central point to allow for a cable to be threaded through.

For more information, see: How to use a spade bit to pull a cable through a wall? |

|||

|

The width of the bit is then stamped on the remaining flat space so it can easily be differentiated from others. | |||