What are the parts of a lead knife? |

||||

|

||||

|

Lead knives are fairly basic hand tools used for cutting. They need to be strong because they are designed for cutting lead and other tough materials, such as plastic or leather. | |||

Blade |

||||

|

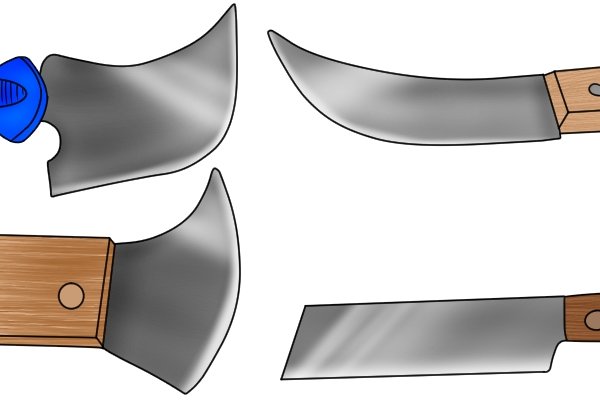

The blades of lead knives are strong and sharp, so they can cut through thin sections of tough materials, like lead came, lead sheet, and plastic. There are four main blade designs and the different shapes can be used for particular tasks. Lead knives come with curved, sickle-shaped, crescent-shaped or straight hacking blades.

For more information see: What are the different types of lead knife? |

|||

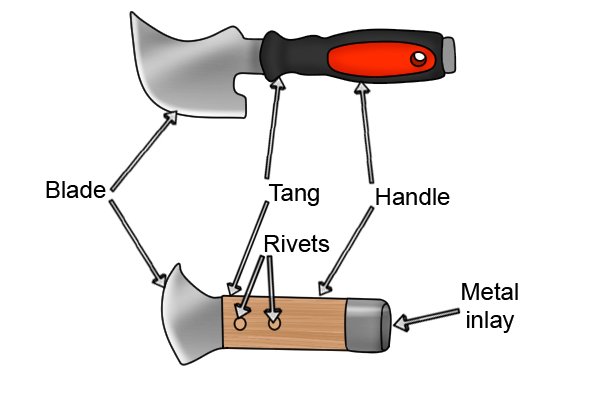

Handle |

||||

|

The handle may be pushed or rocked when cutting the material it’s being used on. It should be comfortable to grip and allow you to move the blade in the direction you need to. | |||

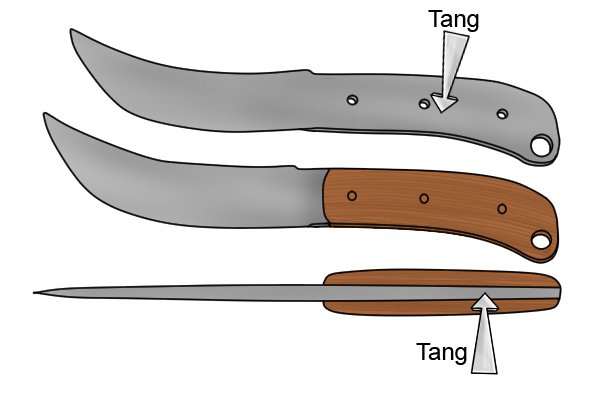

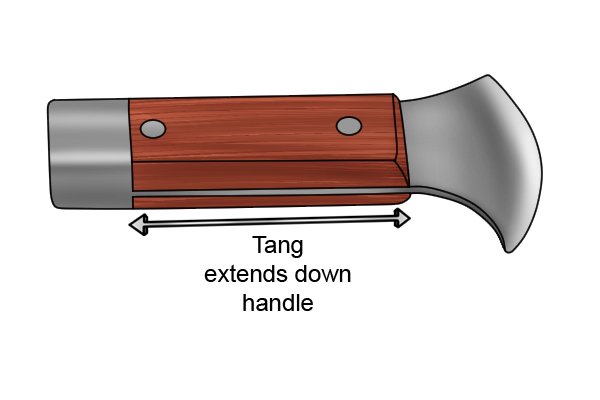

Tang |

||||

|

This is the part of the blade which is used to join it to the handle. It is not fully visible when the handle is in place either side of it. The longer the tang, the stronger the knife will be, as this will carry the blade’s strength further down the handle and provide more leverage. | |||

|

Lead knives should have a tang which goes down most of the handle’s length; they usually have a full or three-quarter tang. | |||

Rivets |

||||

|

If the handle of the knife is made from wood, composite wood or leather it will probably be joined to the tang with rivets, or pins. The more rivets there are, the stronger the joint will be. However, there is an increased chance that dirt and corrosion could get into the riveted joints. | |||

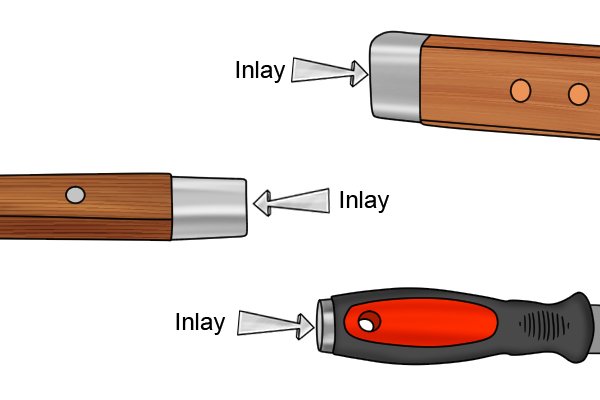

Metal inlay |

||||

|

This feature is not found on all lead knives, but you will find it on many designs, especially lead knives with a sickle-shaped blade. It works as a small hammer and is mostly found on lead knives designed specifically for leaded glasswork.

For more information see: What is a lead knife used for? |

|||