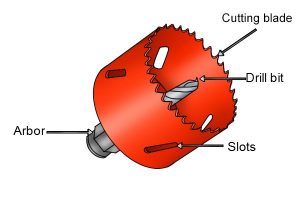

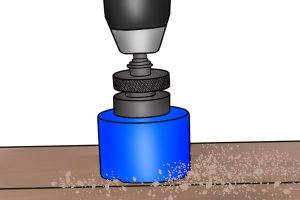

What are the parts of a hole saw?

A now common tool that should be in any DIY’er’s toolbox, the hole saw is the perfect attachment to make large holes in materials. Most hole saw models are the same, including the same key parts of a cutting blade, slots, arbor and a drill bit. Read our full guide on the parts of a hole saw to find out more about each part and its purpose.

Cylindrical Cutting Blade on a Hole Saw

Generally speaking, the fewer teeth per inch on a blade, the larger those teeth tend to be, and the deeper the gullets. This means that with each stroke of the saw, a larger quantity of material is being cut and removed.

As a result, a blade with fewer, larger teeth per inch will cut much quicker than one with more teeth. However, because of this aggressive cutting action, there is a greater chance that the material’s fibres will become torn, creating a rough finish.

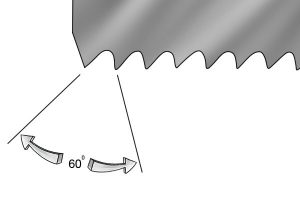

Saw Teeth

The serrated saw teeth of a hole saw are typically set at a 60° angle. This is so that the teeth can “bite” into the material you are cutting.

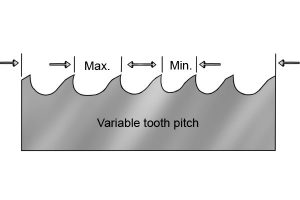

Variable Pitch

Pitch is defined as the distance between the points of two teeth on a saw blade. Therefore, a variable pitch is when the distance between the teeth varies. This irregular set-up actually helps to break sawing rhythms and reduce harmonic vibrations.

Fewer vibrations equals a smoother cut, reducing wear on the blade and lowering noise levels. Chip evacuation is also improved by having a variable pitch; this helps to keep the blade clog free.

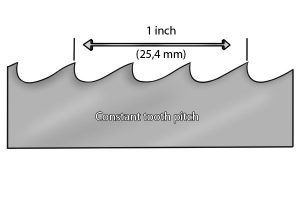

Constant Pitch

A constant pitch is when the distance between those two points remains constant all along the saw.

Saw blades with a constant pitch and a higher TPI (Teeth Per Inch) cut a little slower than variable pitch blades but they make a finer cut.

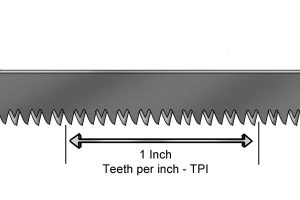

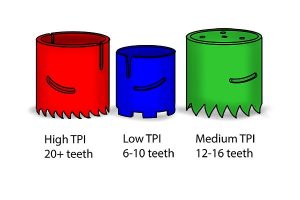

TPI

TPI stands for ‘Teeth Per Inch’ and is a way of measuring the frequency of teeth on a saw blade. Usually abbreviated to TPI, as in, “a blade consisting of 18 TPI”.

Blades with a higher TPI will cut more slowly but will produce a smoother cut because they are less likely to tear at the fibres of your workpiece. Blades with a low TPI will cut faster but the cut will be less smooth as their typically larger saw teeth tend to tear at the fibres of your workpiece. TPI can vary greatly, from as many as 20 teeth per inch to as few as 2 teeth per inch.

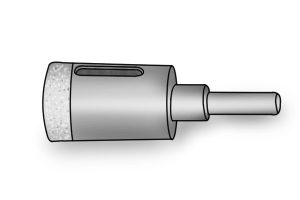

Some hole saws do not have any teeth at all and are instead coated with or embedded with ultra-hard materials such as tungsten carbide or diamonds. These are typically used to cut abrasive materials such as ceramic, glass or brickwork.

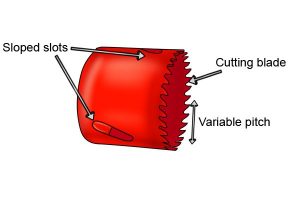

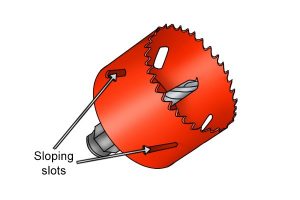

Hole Saw Slots

The slots in the cylinder walls of the cutting blade allow chips and dust to escape more easily. Holes clogged with dust are the chief reason for stuck saw blades.

The amount of slots may vary depending on the make or model, but between 2-6 slots is common on most hole saws. Having more slots is advantageous as this will allow dust and chippings to escape, but you will rarely find hole saws with more slots as this also compromises the strength of the hole saw.

Most slots slope away from the direction that the saw spins to allow dust to escape, though some models may have vertical or even circular slots instead. Whether the slots slope, are circular or straight has very little difference overall, but it is advised to unclog them occasionally as they do help to keep the hole saw cutting effectively.

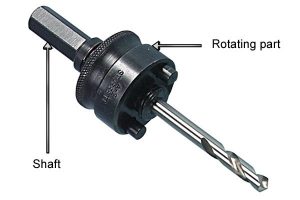

Hole Saw Arbor

An arbor is a type of tool bit that can be used to grip other moving tool components. It is essentially a shaft that supports a rotating part.

Arbors are used in many different applications and in combination with various tools. It is worth noting here that not all hole saws will be supplied with an arbor and it may have to be purchased separately.

Arbors are often found holding hole saws, buffing wheels, drill bits, circular saw blades and sanding discs onto drills, saws, and other power tools.

Hole Saw Drill Bit

Note that, although common, not all arbors have a drill bit attached. The function of the drill bit on the end of the arbor is to create a pilot hole to decrease the chance of the hole saw ‘wandering’ when cutting. The blunt hexagonal end of the arbor is inserted into and clasped by a power drill’s chuck.

Are the drill bits detachable?

The drill bits can be removed if you loosen the set screw in the side of the collar. This can be done with a flat head screwdriver. To reattach, simply insert another drill bit and re-tighten the set screw.

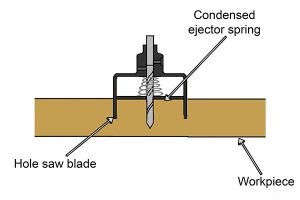

Hole Saw Ejector Spring

Some arbors come with a spring placed over the drill bit called an ejector spring. This spring uses stored mechanical energy to eject the slug from the cylindrical saw blade after your hole has been cut.

When a hole saw fitted with an ejector spring cuts into a workpiece, the spring is condensed against the back plate of the hole saw.

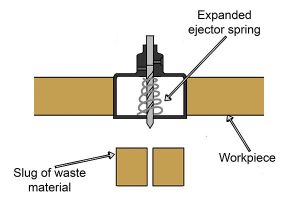

When you have finished sawing your hole, the condensed spring expands and forces out the slug of waste material.

Even with an ejector spring in your hole saw, the slug of waste material can still get stuck from time to time. If this happens, use a screwdriver to jimmy it out by inserting it through the slots in the side of the hole saw.