What are the different types of hole saw?

There are many different types of hole saw to choose from and each has a range of materials they are suited to cutting.

Carbon Steel Hole Saws

Carbon steel hole saws are considered for general-purpose use and have been designed chiefly for the home-improver and DIYer.

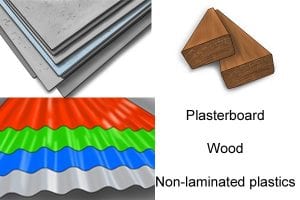

Most suited too…

They are less durable than bi-metallic varieties but work well on light duty applications. They should be used only on soft materials like plasterboard, non-laminated plastic, and wood.

Variable Pitch Bi-Metallic Hole Saws

Some holes saws, manufactured from bi-metal material have hardened teeth made from high-speed steel and variable tooth pitch for fast, smooth cutting. Bi-metal hole saws offer increased safety for the user as they will not shatter under the strain of constant use.

They have a cut depth of 30mm and are suitable for use in most variable speed power drills. Variable speed power drills are preferred as they will give you the ability to cut at different speeds depending on the material you are cutting e.g. wood or metal.

Most suited too…

They are ideal for cutting a wide range of materials including hardwood, chipboard, plywood, non-laminated plastics, plasterboard, and non-ferrous metals.

Variable Pitch Bi-Metallic Hole Saws (Deep Cut)

These rugged hole saws are designed for heavy-duty cutting. They have extra hard, variable pitch teeth for an extended hole saw life and a cut depth of 42.5mm. They are suitable for most variable speed power drills.

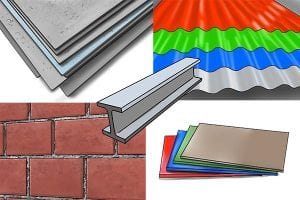

Most suited too…

These hole saws are ideal for use on wood, metal and hard plastics.

Constant Pitch Smooth Cut Hole Saws

Smooth cut hole saws have a constant tooth pitch constructed of hardened, heat and abrasion resisting high-speedteel with a tough alloy body. They are designed for use with battery-operated power drills (18 Volts). Note that the hexagonal shank on this hole saws’ arbor has a slight indentation in it. This indention helps the shank lock into place in a drill’s chuck.

Most suited too…

They are ideal for cutting stainless, tool and mild steel sheeting as well as plasterboard, wood and thin plastics. They have a cutting depth of 13mm (1/2 inch) and fit most cordless power tools.

Tungsten Carbide Tipped Hole Saws

These type of hole saws have tungsten carbide tipped teeth for a fast cutting action and outstanding life.

Most suited too…

These saws have multi-purpose applications and are excellent for users from construction and installation engineers to the DIY enthusiast. They will cut through all woods (including hardwoods non-ferrous metals, plastics, and tiles.

Gulleted Tungsten Silicone/Carbide Grit Hole Saws

These hole saws have special gulleted square teeth coated in a tungsten carbide or silicone carbide grit which allows them to cut through hard and abrasive materials quickly. Their square teeth do not “bite” into the material as standard curved saw teeth do. This allows them to cut into harder materials (like ceramic or glass) without shattering them. The gulleted teeth are similar in shape to the crenelations of a castle.

Most suited too…

They will cut many tough materials, including brick, fibreglass, slate, marble, cement board, laminated plastics, plywood, and cast iron. Although these hole saws can be used on wood, hole saws with standard shaped saw teeth are much more effective.

Welded Shank Soffit Cutter Hole Saws

These types of hole saws have a non-detachable arbor welded on to their base plate.

Most suited too…

The combination of being made from HSS (high speed steel) and having a variable tooth pitch make these hole saws ideal for cutting holes in plywood, metal, and PVC. Their diameter of 70mm also make them perfect for cutting holes in soffit boards for the most common size of vent. They have a cut depth of 47mm (1 7/8 inches).

What is a Soffit?

A soffit is the underside part of an architectural structure such as an arch or the overhanging eaves of a house. They often need holes cut in them for drainage pipes.

Diamond-Edged Hole Saws

Some hole saws don’t have any teeth at all but instead are coated or infused with diamonds for hardness and durability. They have a high heat and wear resistance which makes them very durable. Although these saws have a high heat resistance, it is advised to quench them in water periodically to cool down the blade. Note that this particular hole saw has a round shank. Round shanks can be fitted to any sized drill chuck.

Most suited too…

Diamond-edged hole saws are typically used for drilling through ceramic tiles.

Multi-Hole Saw Set (7 piece)

Multi-hole saw sets are designed specifically for cutting a range of different diameter holes which include the popular sizes (26, 32, 38, 45, 50, 56 and 63mm) and cut holes up to 42mm in depth.

Most suited too…

These hole saws can be used on a wide variety of materials including wood, chipboard, plywood, non-laminated plastics, plasterboard and non-ferrous metals (except stainless steel). They can be used with most power drills.

Speciality Hole Saws

There are many other different tools that can cut a hole in a given material. The hole saws listed below are still considered to be hole saws despite their different designs.

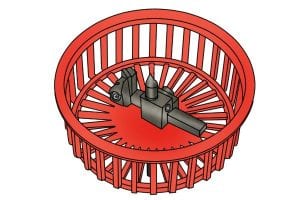

Circular Tile Cutter with Tungsten Carbide Blade

This type of hole cutter is a little different from the standard hole saw. It has a sharp, straight, tungsten carbide blade attached to an arbor which rotates at high speed when used in conjunction with a power drill.

Most suited too…

The blade can be adjusted and set at various distances from the centre point which allows it to accurately cut a variety of different diameter holes. It has a safety cage around its blade to lessen the risk of any expelled chips. It is typically used to cut ceramic tiles.

Tungsten Carbide Tipped Hole Cutter

Hole cutters are a different type of hole saw which, instead of having standard saw teeth, have a tungsten carbide tip (or tips) which, when rotated at high speed, creates a cutting edge. Suitable for use in mains and battery-powered tools though the arbor is supplied separately.

Most suited too…

These saws are heavy-duty general purpose cutters and will power through wood, MDF, plastics, and ceramic tiles.

Tungsten Carbide Tipped Core Drill Bits

The tungsten carbide tips are incredibly hard, and when rotated at high speed, ensure easy penetration with minimal effort. This type of hole saw is not suitable for use with hammer or impact action as this may cause damage to the tips. An arbor may be purchased separately.

Most suited too…

Tungsten carbide tipped core drill bits are used for rotary drilling through masonry, including brickwork, stone and concrete.

Diamond Core Drill Bits

Instead of having pointed saw teeth, this type of hole saw has squared teeth embedded with industrial diamonds for excellent cutting ability. Diamond core drill bits must always be used with power drills rated at 850 – 1000 watts that are equipped with a safety clutch and have a variable speed function. You may need to purchase an arbor separately for these type of hole saws.

Most suited too…

Diamond core drill bits are a type of hole saw suitable for cutting clean holes into brick and concrete. They are called “core drill bits” because they cut out a core of whatever material they are drilling through. Diamond core drill bits should never be used with hammer or impact drilling as this may result in damage occurring to the cutting teeth. Dry cutting diamond core drill bits do not need to be cooled with water whilst in use.

Diamond Core Drill Bits (Wet/Dry Cutting)

These diamond core drill bits can be used for wet or dry drilling and will cut clean holes in most building materials. They are ideal for use with hand-held power tools with a range of between 800 – 1500 watts. These core drill bits need to be used with drill with high wattage so that they have the power to cut into masonry. An arbor may have to be purchased separately.

Most suited too…

Diamond core drill bits can be used to cut holes in granite, concrete, brickwork and stone.

Wet Drilling

Some core drill bits will need to be quenched with water as they cut out a hole in masonry (stone, concrete, brickwork). This is because a lot of friction is created by cutting into dense materials like this. The water will help to increase their working-life as it will keep the drill bit from getting too hot and becoming blunt.

Dry Drilling

Some core drill bits will need to be quenched with water as they cut out a hole in masonry (stone, concrete, brickwork). This is because a lot of friction is created by cutting into dense materials like this. The water will help to increase their working-life as it will keep the drill bit from getting too hot and becoming blunt.