How to use an expansive bit? |

||||

|

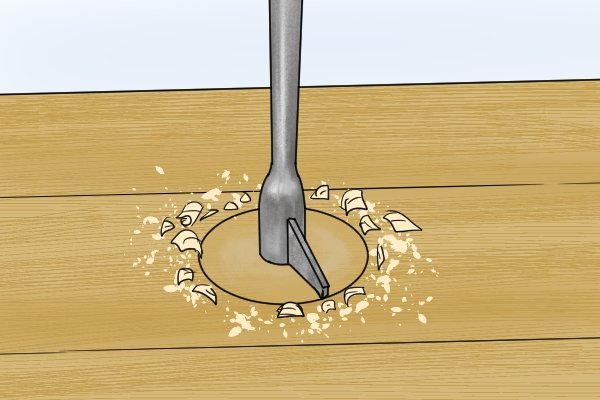

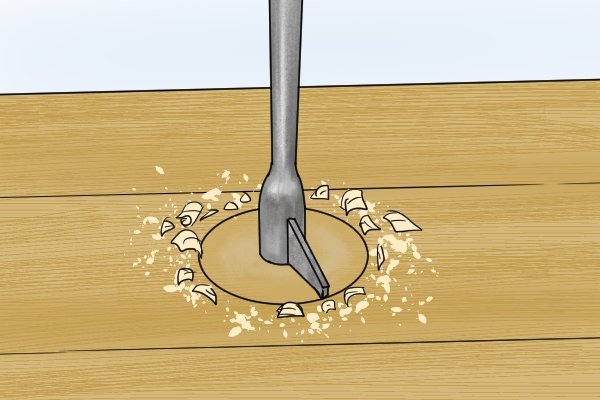

Expansive bits are, in many ways, a cross between auger bits and spade bits in the way they work. Their spurs cut around the edge of a bore hole while their cutting lips prise material from inside, clearing the way for the bit to progress downwards. | |||

|

One of the main differences is that expansive bits take a little bit of elbow grease to use effectively. For this reason, the method for using an expansive bit seeks to minimise the amount of necessary effort as far as possible. | |||

|

If you are working on a project that relies on precision, it may be worth testing your drill bit’s accuracy first by drilling a few test holes.

For more information, see: What sizes of expansive bit are available? |

|||

|

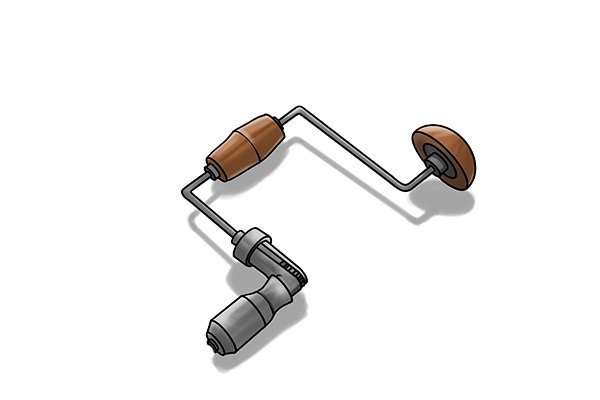

Step 1 – Attach bit to braceWith your expansive bit set to the width of your choice, secure it in the chuck of a large drill brace. |

|||

|

Step 2 – Bore slowlyBoring is a slow process… especially in this case! Working slowly means that you will find the bit resisting the wood less as you turn the brace, and therefore less force will be required. |

|||

|

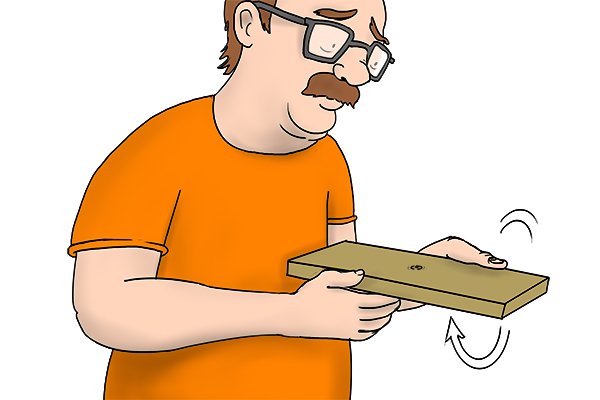

Step 3 – Drill until guide screw breaks the surfaceContinue drilling, checking the reverse side of the workpiece regularly to see when the guide screw breaks through. As soon as it does, remove the expansive bit and flip the workpiece over. |

|||

|

Stopping before the bit breaks fully through the workpiece prevents tear out that would be caused by the outrigger spur. | |||

|

If you are drilling through plasterboard and can’t access the other side, you can ignore this step and continue to drill until the hole is completed. As the reverse side of the plasterboard can’t be seen, tear out is not an issue. | |||

|

Step 4 – Complete the holeInsert the guide screw into the hole it originally made in the surface and complete boring the hole, remembering to continue drilling slowly. |

|||

What is the alternative to a drill brace |

||||

|

You can also use expansive bits with electrically powered drivers. | |||

|

Use your drill driver at a slow speed if you are using an expansive bit to prevent the bit from digging into the workpiece and straining the motor, overheating or generally causing disaster! If you are using a drill press, you can manually set it to the lowest number of revolutions per minute. If you are using a cordless drill driver, you can use the speed setting, or apply only light pressure to the trigger, depending on the model you are using. | |||