Woodturning Chisels Maintenance and Care |

||||

Keep your chisels sharp |

||||

|

Woodturning chisels should kept sharp at all times. Sharp tools make for safer work as they are much less likely to snag or bind in a workpiece. | |||

|

Woodturning chisels can dull very quickly on a lathe, so they will need to be sharpened frequently and as quickly as possible. Below are some of the most common ways to sharpen a woodturning chisel. | |||

|

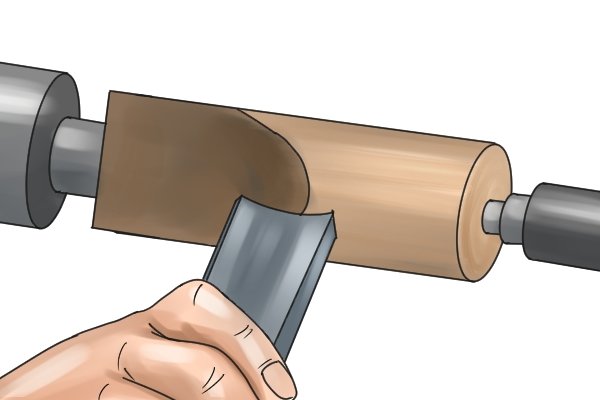

Bench grinderThe quickest way to sharpen a woodturning tool is to use a bench grinder. Their grinding wheels can be interchanged for various levels of abrasiveness and many woodturners have a grinding wheel purely for their lathe tools. |

|||

|

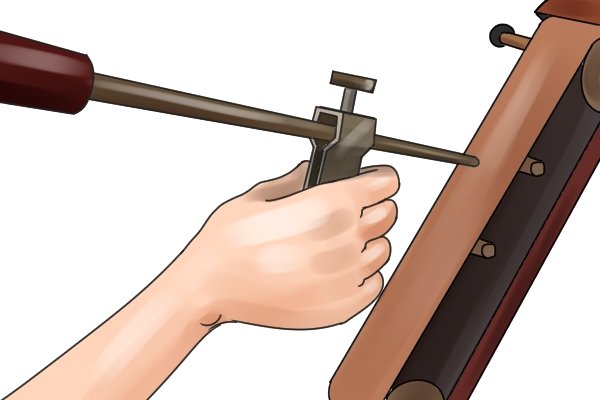

Belt sanderA belt sander, used in conjunction with a sharpening jig, can be an effective grinder. Interchangeable sanding belts offer a variety of grit sizes and levels of abrasion. |

|||

|

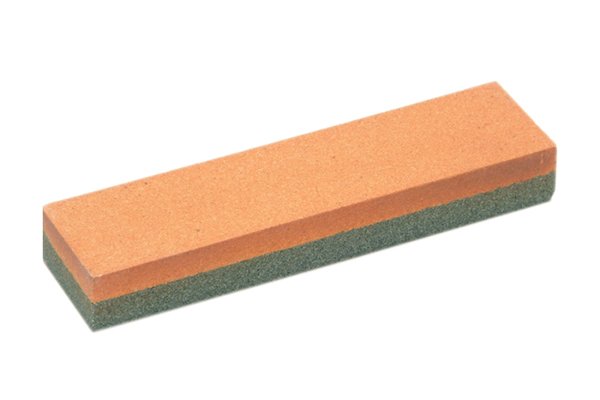

Sharpening stoneA sharpening stone can be used to resharpen a lathe tool’s cutting edge. However, they can be time-consuming and fatiguing to use. If you have a lot of tools to sharpen, you’re probably better off with bench grinder. |

|||

Sharpening guide |

||||

|

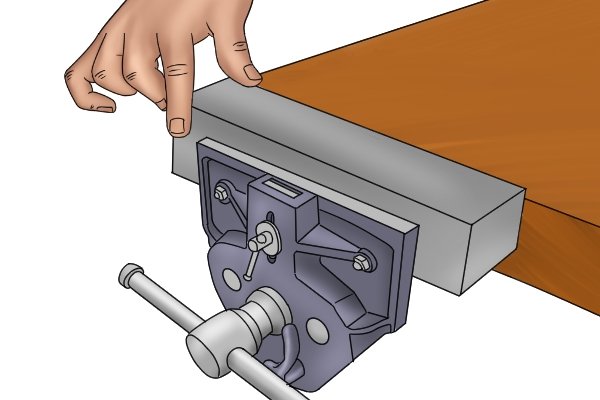

Step 1 – Secure sharpening stoneSecure a sharpening stone (fine side up) in a vice or on a suitable worktop. This will stop any unwanted movement when you come to start sharpening your tools. |

|||

|

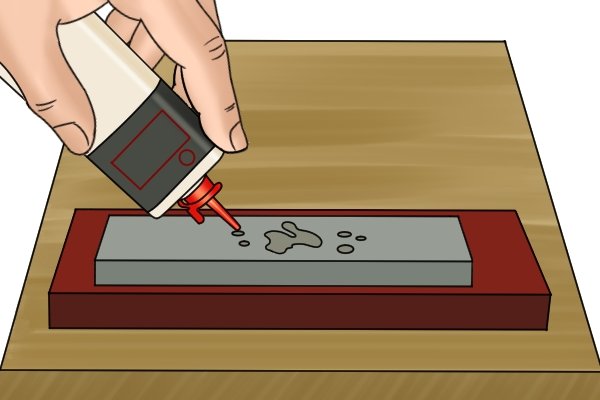

Step 2 – Oil stoneApply some lubrication (preferably cutting oil) to your sharpening stone. This will ease the movement of your tool’s blade as it is rubbed across the stone. |

|||

|

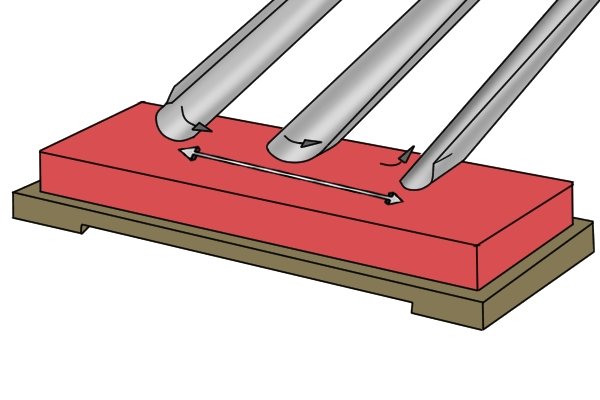

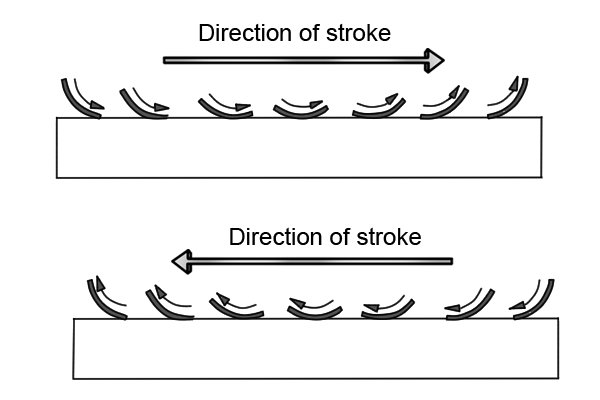

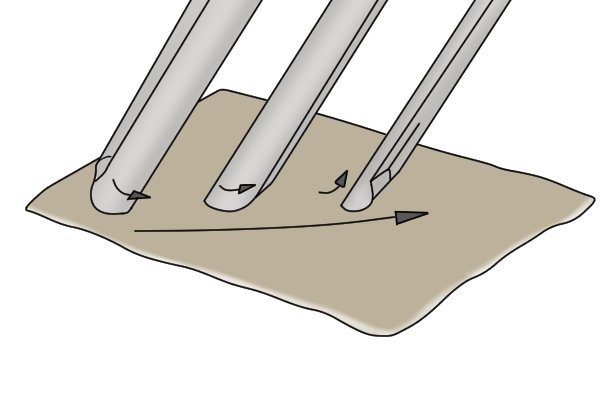

Step 3 – Sharpen outer bevelHold your gouge horizontally and at a right-angle to the sharpening stone, with the back of the blade resting on the stone. Raise the handle so that the bevel lies flat on the stone and begin moving the blade back and forth along the stone, twisting it as you go. (Note that this sharpening guide is for gouges, for flat bladed chisels there would be no need to twist). |

|||

|

Do not over-twist as you move the chisel back and forth along the stone. Over-twisting could lead to rounding off the corners of the blade’s cutting edge. | |||

|

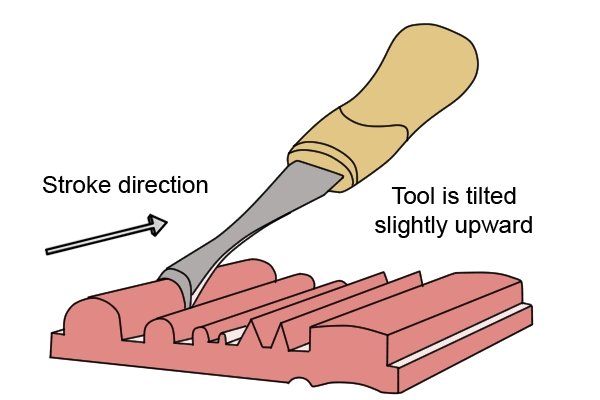

Step 4 – Sharpen inner bevelUsing a honing strop or conical slip stone, turn the chisel over, raise the handle, and begin sharpening the inner bevel. Always pull the chisel backwards when honing the inner bevel. |

|||

|

Step 5 – Polish outer bevelOnce you have honed the bevel to your required sharpness, remove any burrs and polish up your cutting edge by rubbing it against a leather strop. |

|||

|

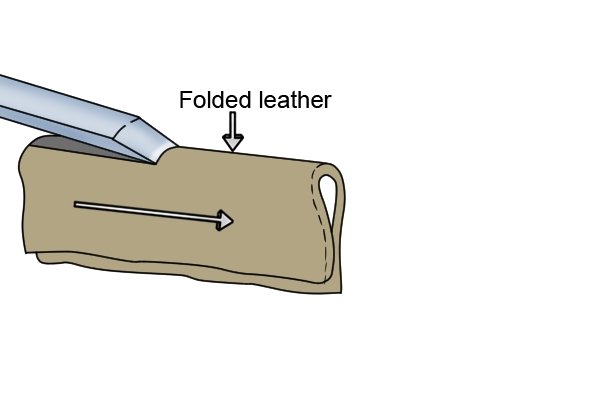

Step 6 – Polish inner bevelFold your leather strop over to create a curved surface and repeat the polishing on the inner bevel. |

|||

| Images on this page are used with the kind permission of Brian Clifford at www.turningtools.co.uk | ||||