What is a ratchet spanner?

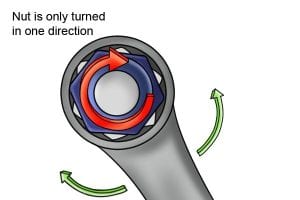

A ratchet spanner uses a mechanism which allows an open-ended, flare or ring head to turn a fastener in one direction but not the other while remaining fitted to the fastener head.

How do you use a ratchet spanner?

Turning the spanner over or flicking a lever changes the direction of movement.

Some ratchet spanners have arrows etched into the surface of the tool to indicate which direction the torque is (which direction the nut will be turned in).

Ratchet spanners are useful because they don’t need to be removed from the head and relocated every time the limit of the turning arc is reached, like non-ratcheted spanners. They are turned back and forth repeatedly but the nut is only turned in one direction. This saves time and is less fiddly.

On the downside, the mechanism makes the spanner weaker than non-ratcheted spanners so they cannot tighten the fastener as firmly.

What are the different types of ratchet spanner?

Ratchet spanners can have two ratcheted heads or one ratchet and one non-ratcheted head. The non-ratcheted head can start or finish the task when the fastener is at it’s tightest and the ratchet head can do the rest.

Ratchet spanner head sizes range from 6mm to 40mm or 5/16″ to 2″ and the tool length from 130mm (5″) to 450mm (1′ 5″), increasing with head size. The larger tools require a stronger mechanism and a longer, stronger handle to provide enough leverage to tighten or loosen the fastener without breaking.

Some ratchet spanner designs have interchangeable ‘bushes’ or heads which fit into a larger head size and reduce the spanner size.

Ratcheted head types

The most common ratcheted heads are ring heads. They have a 12-point profile (see What is a ring head?) made from a plastic component which twists in one direction within the spanner head housing.

Some ratchet spanners have ‘reversible’ heads which accommodate two sizes, one on each face of the spanner. A lever has to be moved across to change the direction of the ratchet mechanism. Ring heads are sometimes flexible.

Open-ended spanners can also have a ratchet mechanism although instead of the ratcheting mechanism being on the inside of the spanner, a spring loaded pawl sticks out of one face of the profile and the fastener head acts as the gear.

‘Ratchet-effect’ open-ended heads have a modified profile which catches on the fastener in one direction but not the other. Turning the spanner over changes the direction of torque.

Flare nut spanners can be ratcheted too. They look different to non-ratcheted flare nut spanners but are used for the same sort of jobs.

How does the ratchet mechanism work?

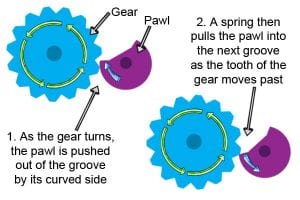

A ratchet mechanism works using a spiked gear and one or two spring-loaded pawls.

As the gear turns, the end of the pawl slides up a curved surface of the gear and then drops down into a groove. This makes the clicking noise a ratchet spanner makes.

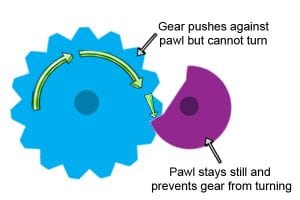

If the gear is turned the other way, the end of the pawl is pushed into the groove and prevents the gear from moving. The spanner can then function as normal.

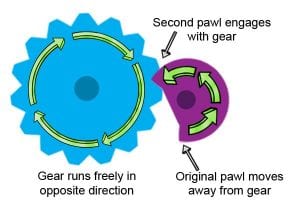

Turning the tool over reverses the direction of the turning force…

…but most ratchet spanners have two pawls and a lever which switches the active pawl to one acting in the opposite direction.

The number of teeth on the gear dictates how quickly the spanner profile engages with the fastener head. The more teeth, the sooner it engages. This maximises the length of turning arc which is particularly important in tight spaces. The best ratchet spanners are the ones that connect within 5 degrees (gear has 72 teeth).