What is a mitre saw? |

||||

|

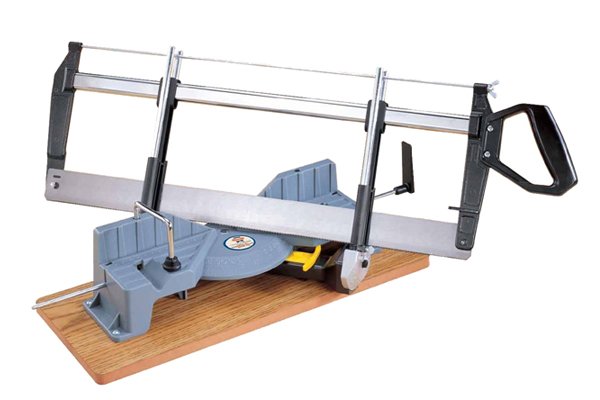

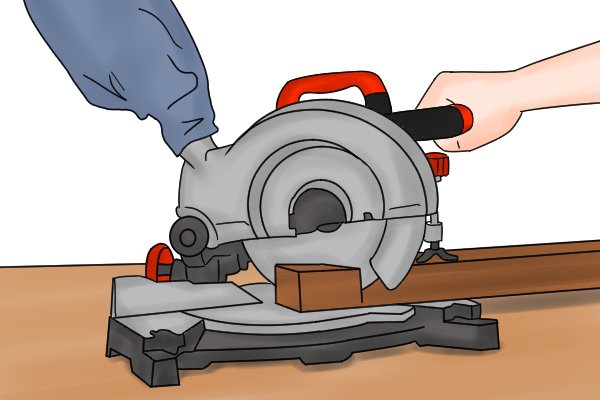

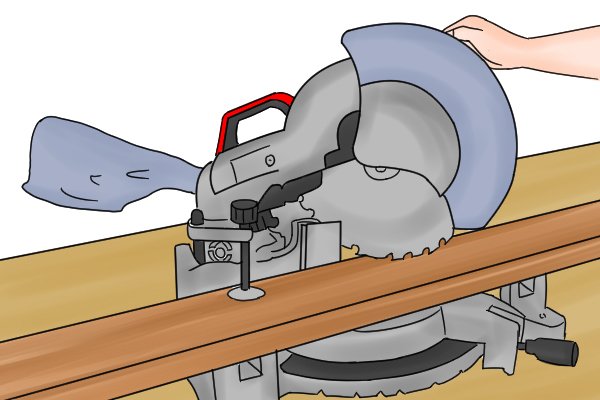

Mitre saws are hand or power-operated saws that are used to make accurate cuts. A power-operated mitre saw is a circular shaped saw that is pulled down at a selected angle to cut material. | |||

|

Manually-operated mitre saws are still used, however, they have been largely displaced by power-operated mitre saws. | |||

|

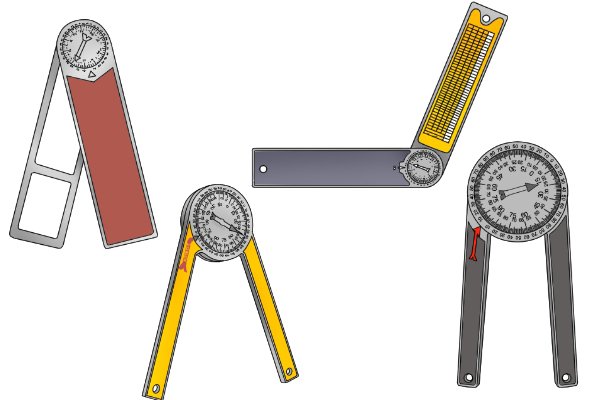

Mitre saws are commonly used in framing and the cutting of mouldings, two applications that often require a large number of very exact cuts to be made. Powered mitre saws can cut through materials quickly, and, with the aid of a mitre saw protractor, can ensure the cuts are to the desired angle. | |||

|

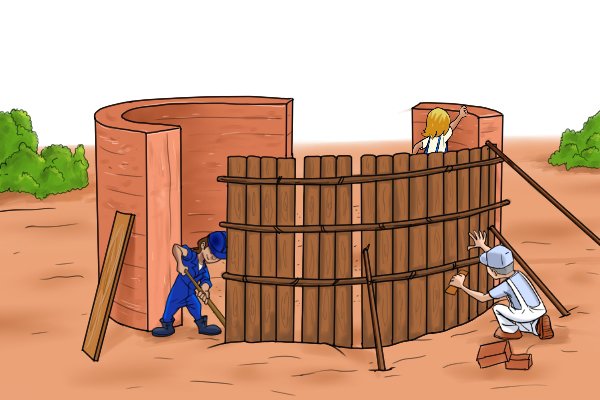

Framing is the process of fixing together certain materials (wood or steel) to provide a structural support. | |||

|

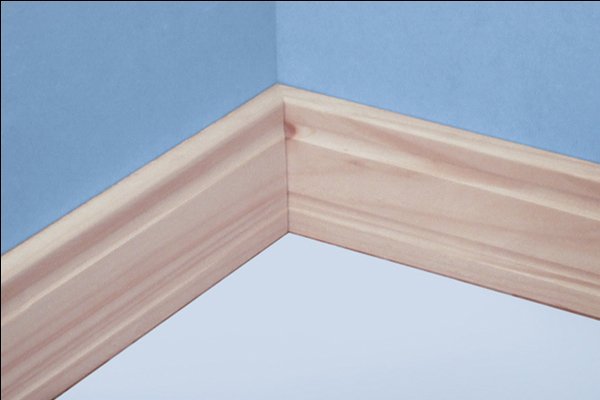

Moulding (more commonly known as coving) is a shaped strip of material (profiles), typically wood, that is fitted for decorative purposes. | |||

|

An example of a moulding is the skirting board in a home, used to cover the joint between the floor and the wall. | |||

What types of cut can a mitre saw produce? |

||||

|

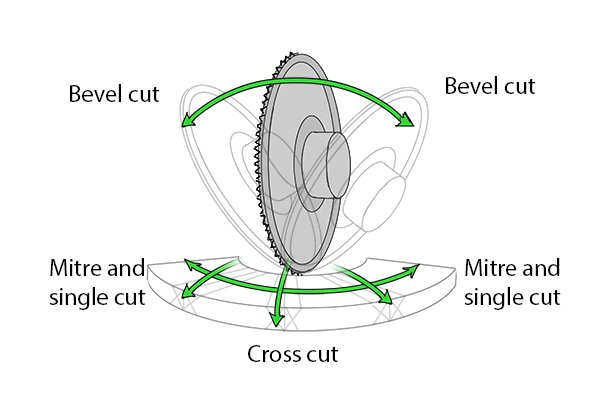

Mitre saws are available with different blade adjustment settings, allowing them to produce single cuts, cross cuts, bevel cuts, compound cuts and mitre cuts. | |||

|

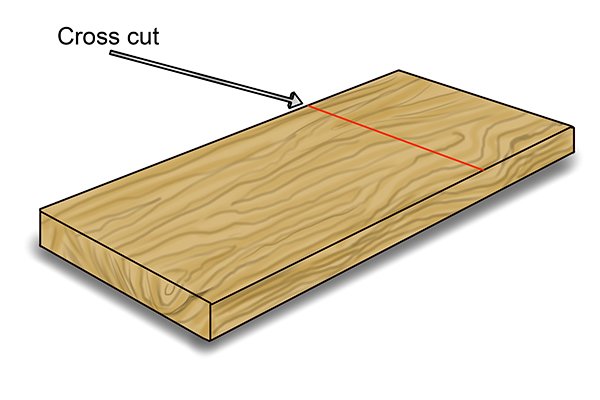

Cross cutsA cross cut is one made perpendicular to the grain of the material. Perpendicular is a term that describes the link between two lines which meet at a right angle (90 degrees). |

|||

|

When you are installing flooring, cross cuts can be used to provide a straight clean cut to the end of each floorboard. This helps the flooring to be cut to size and fitted perfectly without any problems. | |||

|

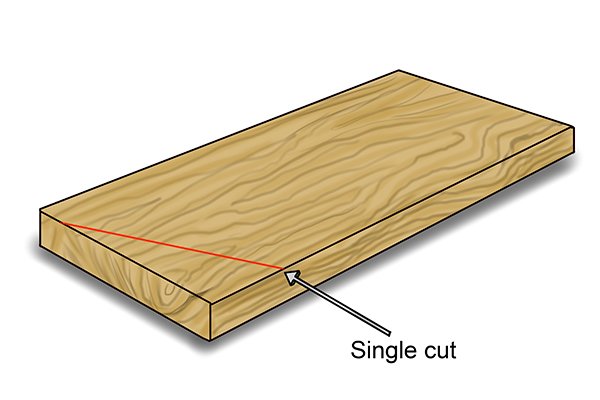

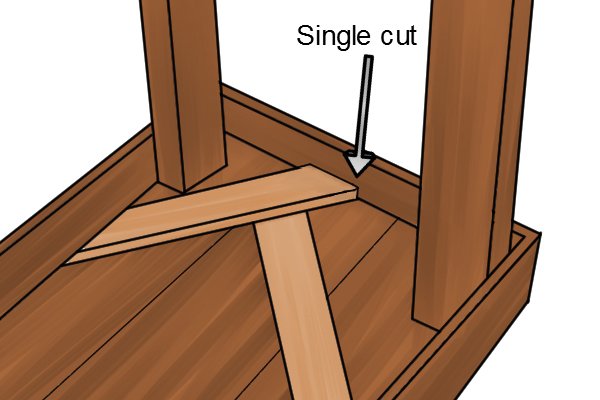

Single cutsSingle cuts are angled to a workpiece. A single cut could include a cross cut or a single mitre cut but mitre saws are also capable of making single cuts at angles other than 45 degrees and 90 degrees. |

|||

|

Single cuts can be used in the construction of furniture to provide a stronger structure. | |||

|

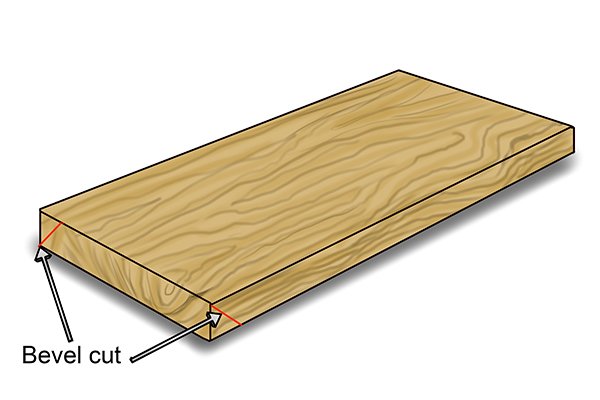

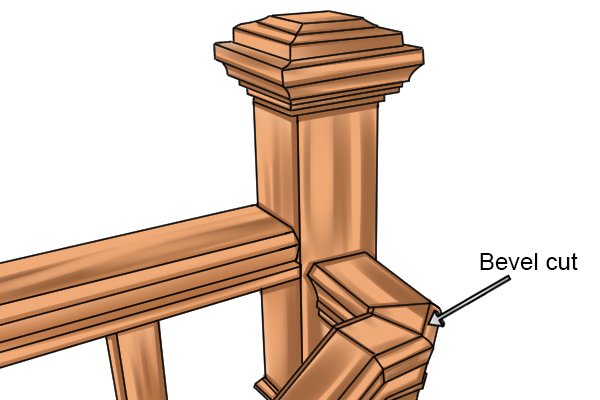

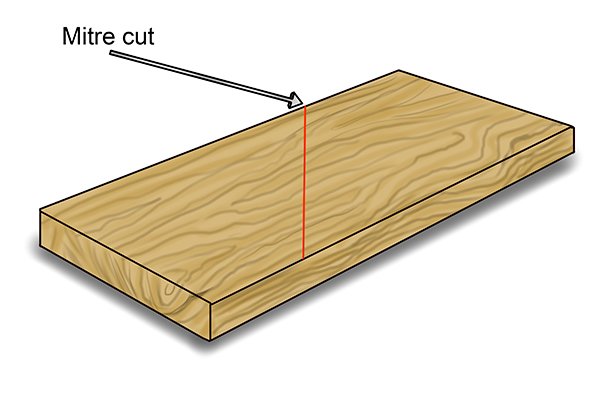

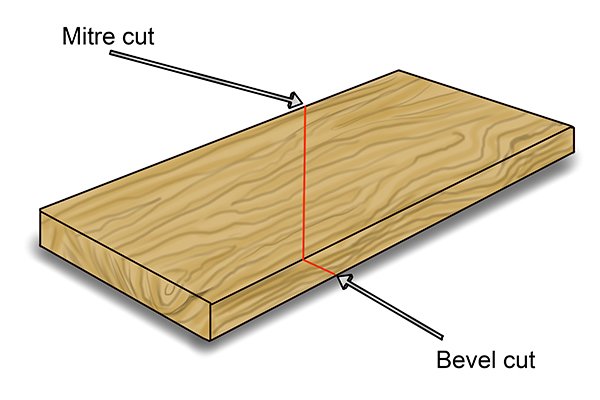

Bevel cutsA bevel cut is an angled cut between 0-45 degrees to the edge of the material. |

|||

|

A bevel cut can be used when installing stair banisters (handrails). | |||

|

Mitre cutsMitre cuts are angled cuts, commonly at 45 degrees. Mitre cuts are used to produce mitre joints. |

|||

|

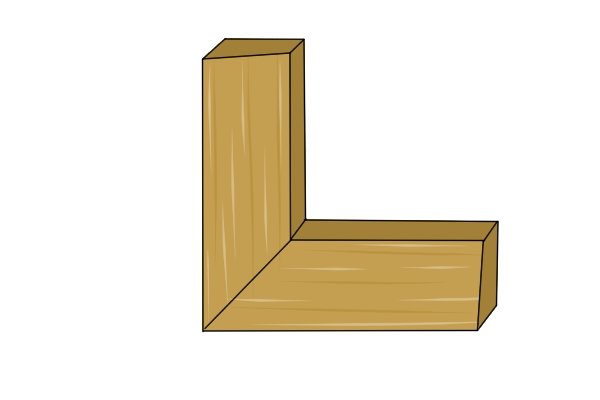

Mitre jointsMitre joints are when two parts are joined to form a corner. Mitre joints are commonly used in moulding, door frames, pipes and picture frames. |

|||

|

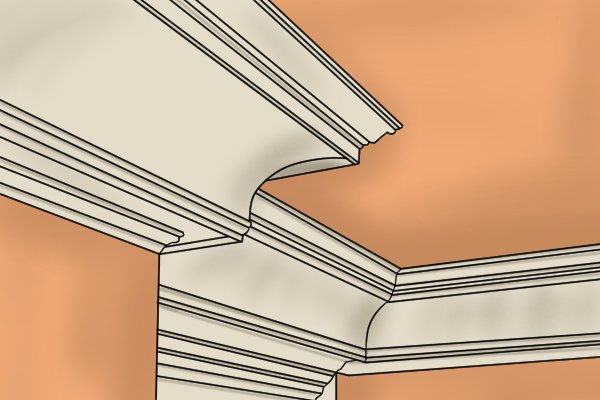

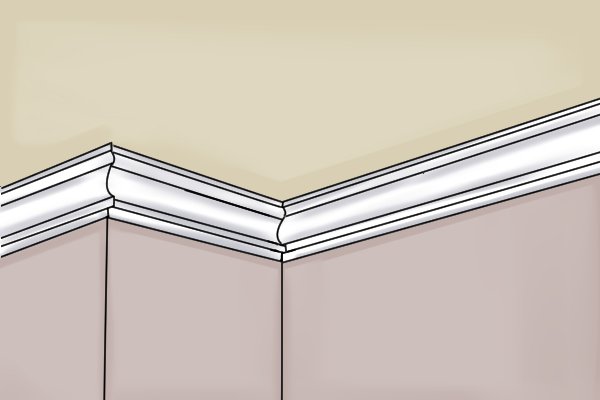

Compound cutsA compound cut is a mitre cut and a bevel cut together. An example of when compound cuts are used is when you are installing crown mouldings. |

|||

|

Crown moulding is the shaped strips of material that can be fitted around the top of a room where the wall meets the ceiling. | |||

Summary |

||||

|

A mitre saw, used in conjunction with a mitre saw protractor, can be used to accurately cut angles for single, mitre and compound cuts without any calculations. The accuracy these tools provide is important for applications in which materials must fit together properly to create a neat finish.

To find out more about how a mitre saw protractor works, see How does a mitre saw protractor work? |

|||