What are nut splitters made of? |

||||

| Shop for Nut Splitters | ||||

|

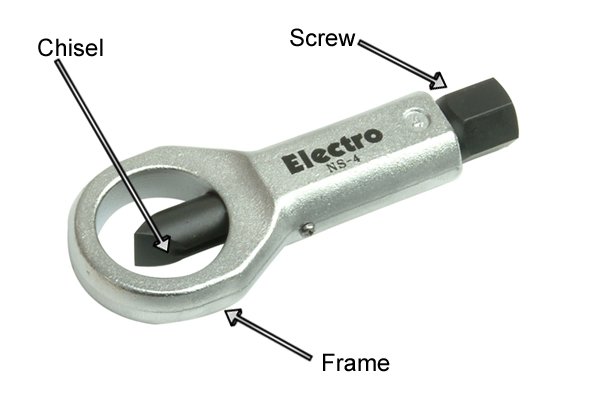

The frame of a nut splitter is made of steel, while the chisel and screw can be made of chrome molybdenum or hardened high carbon steel. | |||

|

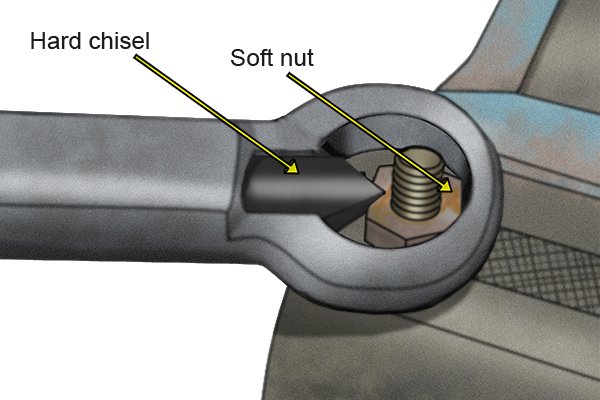

The chisel of a nut splitter has to be made of a harder material than the nut it’s trying to split. This is why hardened high carbon steel and chrome molybdenum are used for this part of the nut splitter. | |||

What is high carbon steel? |

||||

|

High carbon steel is steel with a carbon content of between 0.9-2.5%. This carbon content is required if the steel is to be heat treated to improve its strength, hardness and ductility. | |||

|

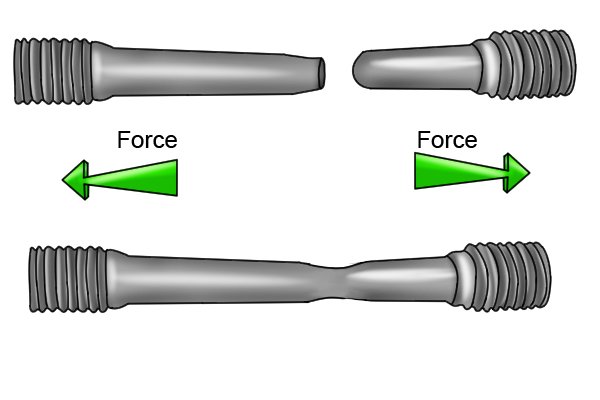

What is ductility?Ductility is the ability of a material to change its shape or stretch under tension, without breaking. |

|||

|

Compared with low and medium carbon steel, the cutting edge of a high carbon steel chisel will stay sharp for longer, but is more susceptible to rust if left exposed to moisture. | |||

What is chrome molybdenum? |

||||

|

Chrome molybdenum, also known as chrome alloy or chromoly, is a steel alloy that contains chromium and molybdenum among its alloying elements. There are more than 20 different grades of chrome molybdenum with varying properties to suit different applications. One big advantage of chrome molybdenum over other steels is its ability to be hardened considerably more than low carbon steel. | |||

|

It also lends itself to a process known as case-hardening or surface-hardening. Surface-hardening hardens the outer surface of the metal, improving its strength and wear resistance while leaving the rest of the metal more ductile and therefore less brittle (reducing the chances of it breaking). | |||