What is a Sheradised Nail?

You have probably heard about galvanised nails but if you are new to DIY or construction you may find yourself asking what are sheradised nails? sheradising is similar to galvanising in that it includes coating the nails in Zinc in order to improve their corrosion resistance, however, the process in which it is completed is different.

In this Wonkee Donkee guide, we explain what is a sheradised nail, what sheradised nails are used for and what the differences are between sheradising and galvanising.

Why choose a Sheradised Nail?

As we previously mentioned, sheradising provides a corrosion-resistant layer to nails which makes them suitable for a whole range of tasks. The process of sheradising works so well that these nails can be used outside in all types of weather and environments without compromising their structure.

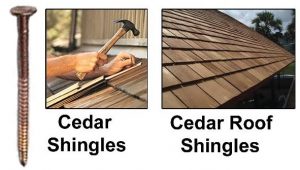

This is why sheradised nails are favored for many outdoor projects where exposure to the elements is constant. Examples of these projects are fencing or decking jobs, whereby the structure tends to be constantly surrounded by the environment and has little protection from the elements. Sheradised nails can also be used in roofing projects, although this is less common.

What are the different types of Sheradised Nails?

As with galvanising, sheradising is completed on both iron and steel nails in order to improve their resistant properties. That means that although the nails are always made from the same two materials, the main difference between sheradised nails is the different sizes and head shapes.

Due to their anti-corrosion properties, sheradised nails are used for a whole range of purposes and they are equally as good for outdoor or indoor use. This has lead to sheradising becoming a standard process on a range of different nail designs. From your local building merchants, you can now buy sheradised versions of lost head nails, panel pins, oval brads, annular ring shank nails and a whole load more.

What is Sheradising?

The process of sheradising steel begins with heating the material to extremely high temperatures. Once the steel is hot enough it is placed into a drum along with Zinc dust (and sometimes other elements such as sand) and the drum rotates. The steel is kept at a high temperature and with the rotations of the drum, the Zinc evaporated and diffuses until it bonds with the steel and creates a covering by gripping too and filling tiny crevices.

Sheradising vs Galvanising

In the previous section, we looked at what is sheradising and explained the process of sheradising steel. In another Wonkee Donkee guide, we have also looked at what is galvanising. But how do the processes differ?

In simple terms, sheradising requires high temperatures and a rotating drum in order to vapourize the Zinc which then clings to the steel, whilst galvanising also requires high temperatures but involved the steel being dipped in a range of baths.

The main differences between sheradising and galvanising is the cost (sheradising is much more expensive) and the scale (galvanising can be completed on a much larger scale). Both of these reasons are why galvanising is a much more commonly completed process and why products such as glavanised nails are much cheaper than sheradised nails.

The one advantage to sheradising is that the vapourisation process it provides a much more complete Zinc coverage to steel, making it less likely to have weak areas where there is a reduced amount of resistance.