What are metal anchor expansion tools made of? |

||||

|

Metal anchor expansion tools are manufactured from steel. | |||

Why are they made of steel? |

||||

|

There are three main reasons that metal anchor expansion tools are made from steel: strength, cost and ease of manufacturing. | |||

|

Steel gives the metal anchor expansion tool the strength that’s required to pull the screw head of the hollow wall anchor back. | |||

|

Of the materials that have the required strength, steel is one of the cheapest, meaning tools can be made from it at an affordable price. | |||

|

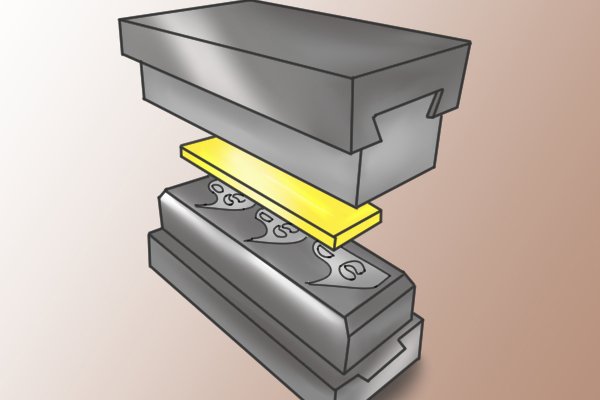

Steel can be formed into the required shapes to make a metal anchor expansion tool using several manufacturing methods. The manufacturing method and corrosion protection applied will influence the quality and cost of the finished tool. For more information see How are metal anchor expansion tools manufactured? | |||

What are the handle sleeves made of? |

||||

|

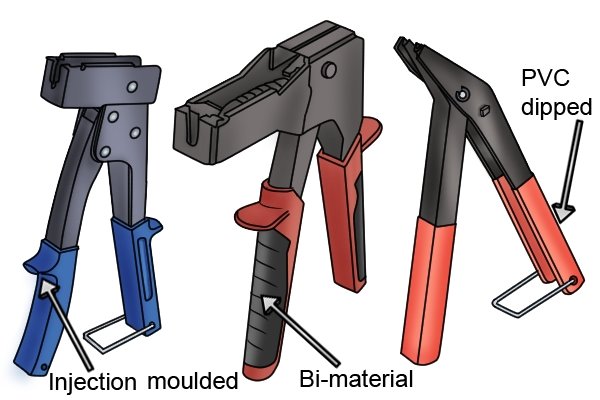

The handle sleeves fitted to some metal anchor expansion tools are made of either PVC (polyvinyl chloride) or a thermoplastic such as nylon. Handle sleeves made of thermoplastic may also have a section coated with TPR (thermoplastic rubber), in which case they may be called soft grip, bi-material or ergonomic handles (shaped and designed for comfort, safety, productivity and efficiency). | |||

|

Why is PVC used?PVC is the common abbreviation for polyvinyl chloride, a plastic polymer. The PVC handle sleeves of metal anchor expansion tools are produced using a manufacturing method called dip moulding. PVC handles improve the comfort and grip compared to plain metal handles. PVC can be made in a wide range of colours, and is flame retardant and UV (ultra violet) resistant. |

|||

|

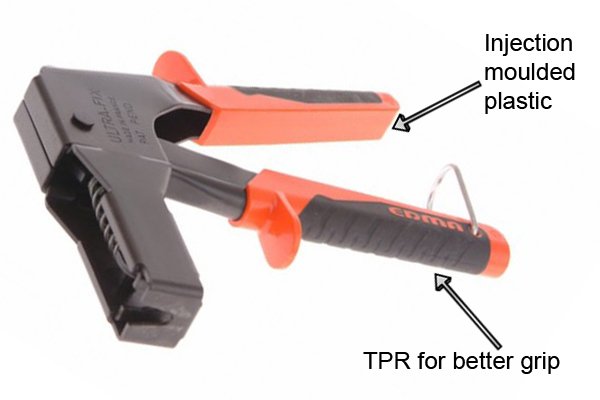

Why are thermoplastics used?Nylon and other thermoplastics are used to make the handle sleeves of metal anchor expansion tools as they can be easily formed into ergonomic shapes by injection moulding. When manufactured in high volumes, these materials and manufacturing processes are cost-effective and quick… |

|||

|

…and allow TPR (thermoplastic rubber) to be added to the handle sleeves. | |||

|

What is TPR?TPR (thermoplastic rubber) is a type of thermoplastic which combines the advantages of rubber materials with those of plastic materials. It is used on the handles of better quality tools to improve their grip and comfort. |

|||

|

Metal anchor expansion tools with handle sleeves featuring TPR may be referred to as being bi-material, ergonomic or having a comfort grip. | |||