How are manual post-hole augers manufactured? |

||||

|

Most of a manual post-hole auger is made from tubular steel. The threads are made from sheet steel and some handles are made from wooden dowel. | |||

Manufacturing tubular steel |

||||

|

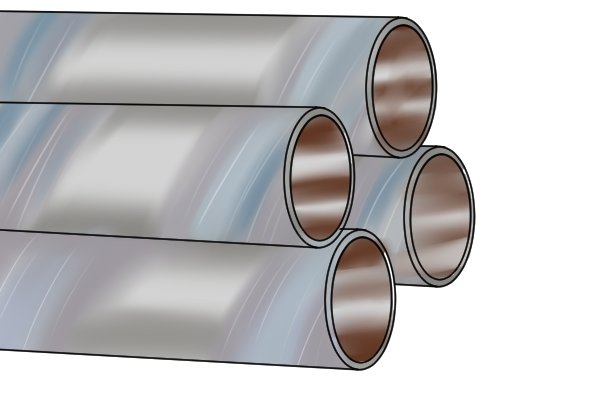

There are two methods of manufacturing tubular steel. One involves shaping a solid cylinder of steel into a pipe (seamless-pipe manufacturing), the other uses welding to join metal sheets together to form a pipe (welded-pipe manufacturing). | |||

|

Seamless-pipe manufacturingA solid piece of steel (called a ‘billet’) is shaped, by applying heat and pressure, into a long cylinder shape called a ’round.’ |

|||

|

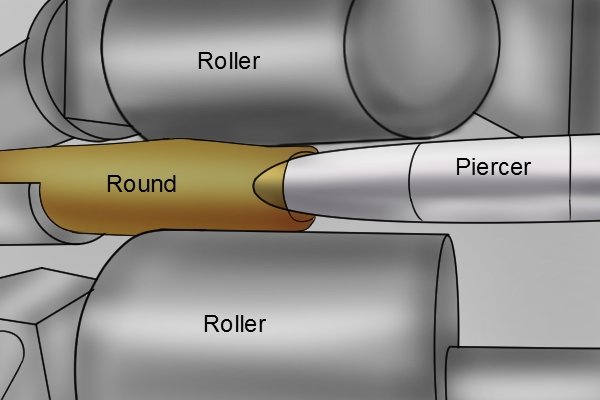

The round is heated until it is white-hot and then run through rollers which squeeze it and lengthen it. A bullet-shaped ‘piercer’ is pushed down the middle and along the length of the round. The round emerges as a tube of steel wrapped around the piercer. | |||

|

The whole object then undergoes another session of squeezing through rollers to form the correct thickness of pipe. The piercer is then removed. | |||

|

The hot steel pipe is cooled in water after which it is ready to be cut up and welded together into the shaft, handle and T-joint of a manual post-hole auger. | |||

|

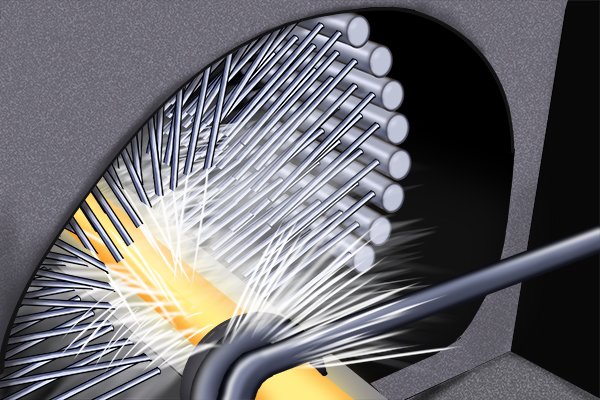

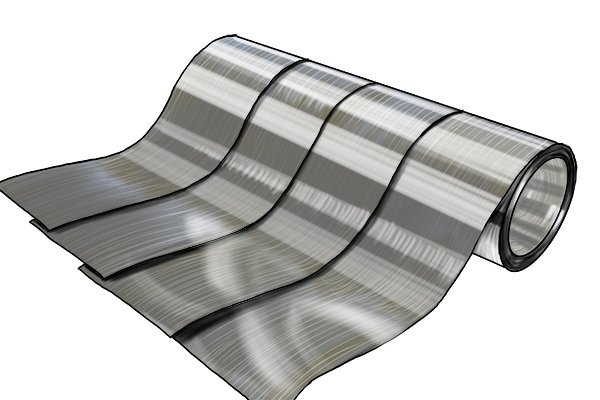

Welded-pipe manufacturingWelded pipe is made from long sheets of metal called skelp. The skelp is unrolled, heated and twisted into a tube. |

|||

|

It can be curled lengthways… | |||

|

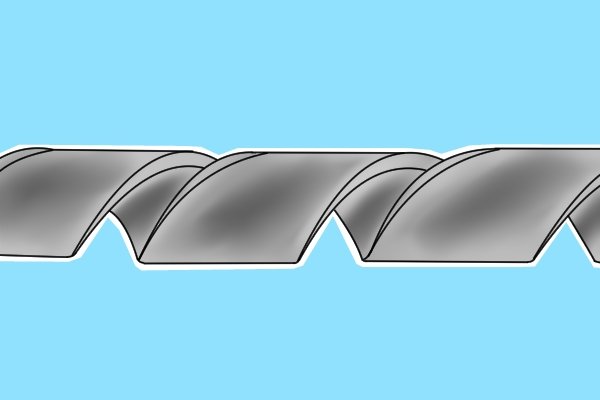

…or twisted into a spiral… | |||

|

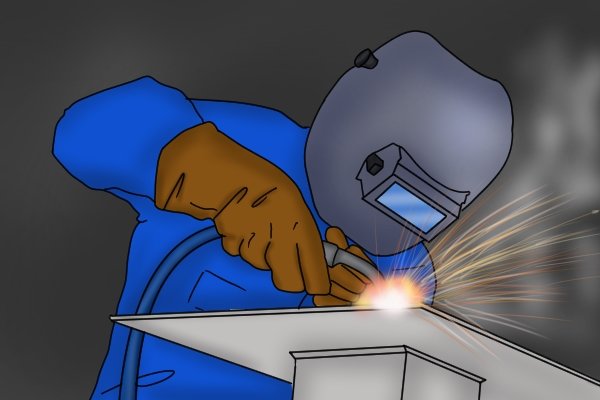

…before it is welded along the seams and passed through rollers to flatten the welds and correct any faults in the shape of the tube. | |||

Manufacturing threads or cutting plates |

||||

|

To make the threads or cutting plates of a manual post-hole auger, a sheet of steel is cut… | |||

|

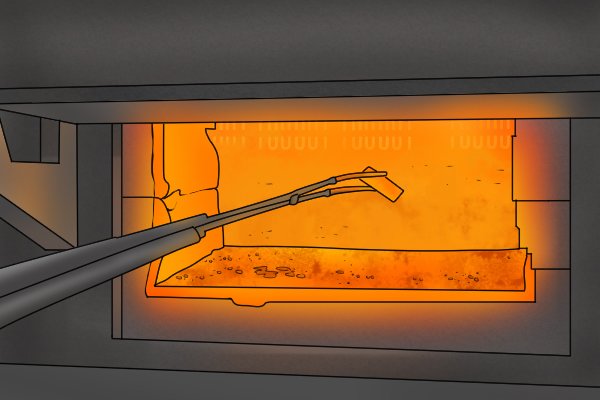

…heated and squeezed between rollers… | |||

|

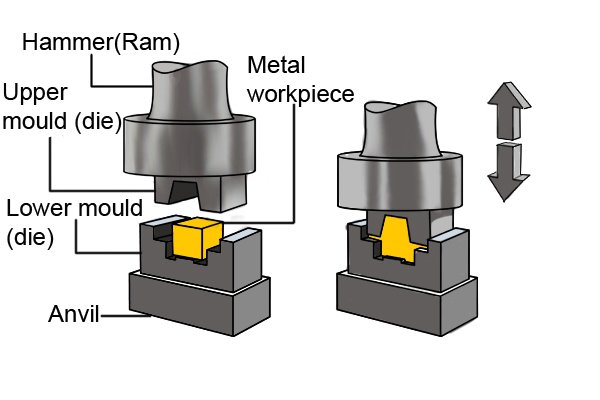

…and shaped with hammers to form the thread or cutting plate. | |||

|

The finished thread is welded onto the shaft and all the metal parts of the manual post-hole auger are coated with a powder coating (see What are manual post-hole augers coated with?). | |||

Manufacturing wooden handles |

||||

|

Rectangular pieces of wood are fed into a machine which shaves off strips of wood like a pencil sharpener to create cylindrical dowels. | |||

|

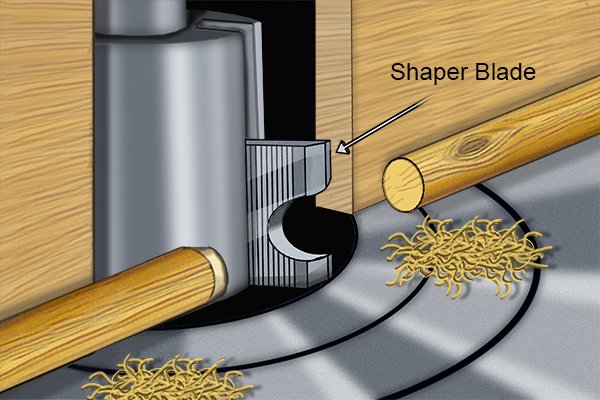

The dowels are cut to the right length for a manual post-hole auger handle and specialised ‘shaper’ blades are used to refine the shape of the handle to make it more comfortable to use. | |||

|

Finally, a coat of wood preservative is applied to the handle to protect the wood from rot. | |||

Manufacturing hand grips |

||||

|

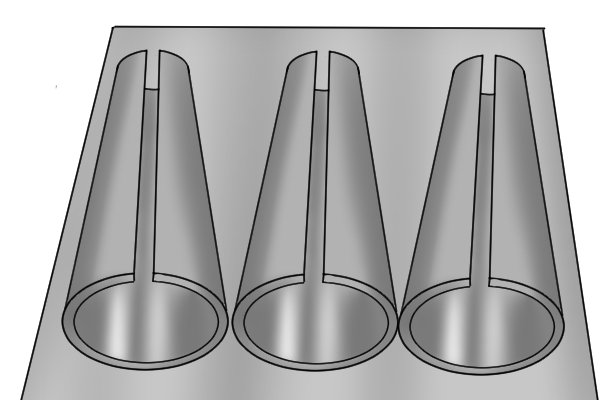

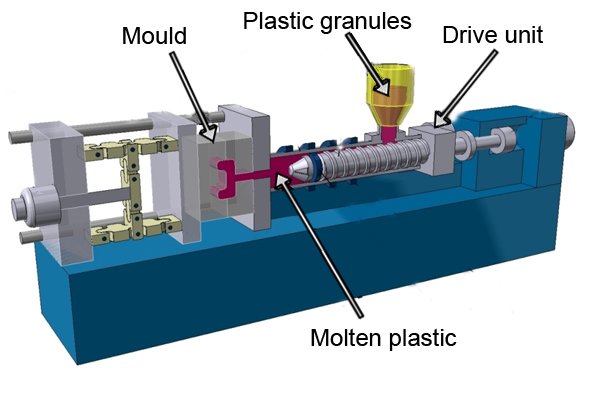

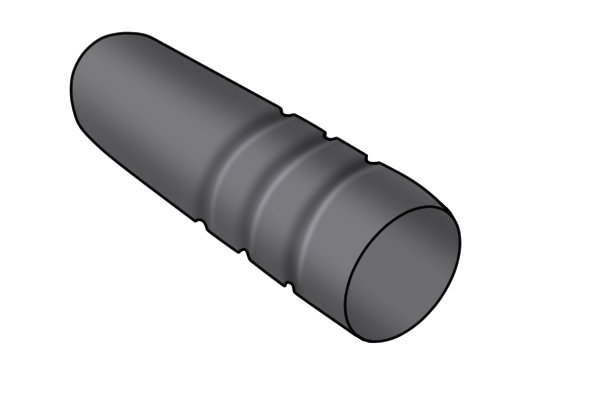

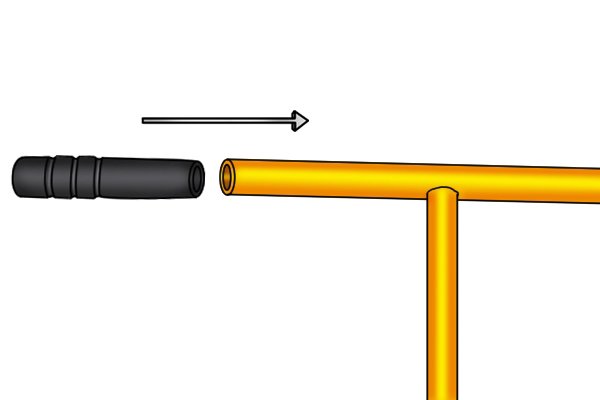

Hand grips are usually made from rubber, foam or plastic. All these materials are made into hand grips using a molten form of the material pressed into a mould.

Image supplied courtesy of Rutland Plastics. |

|||

|

The interior of the mould is the shape of the hand grip so when the material solidifies a hand grip is produced. | |||

|

Excess material that did not fit in the mould is cut off and the hand grip is ready to be glued or slid onto the manual post-hole auger handle. | |||