What are Lead Soakers?

Lead soakers are waterproofing flashing products that are installed between tiles and any objects or features that cause breaks in the structure of the roof. Most commonly, lead soakers are used to seal the gap between tiles and chimneys, skylights, ventilation pipes and any other features that protrude through the roof.

Soakers are fitted underneath the tiles surrounding and fit up against the obstacle, preventing water from entering the roof space causing damp or water leaks. Correctly installing lead soakers within a roof will weatherproof the roof, with water running down off the tiles and soakers into the guttering system.

What are lead soakers made from?

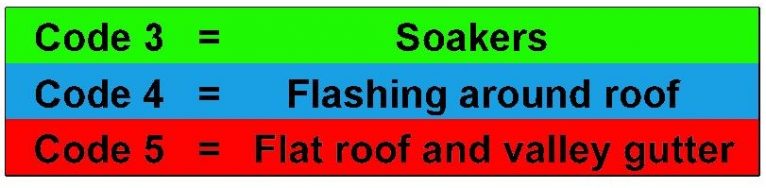

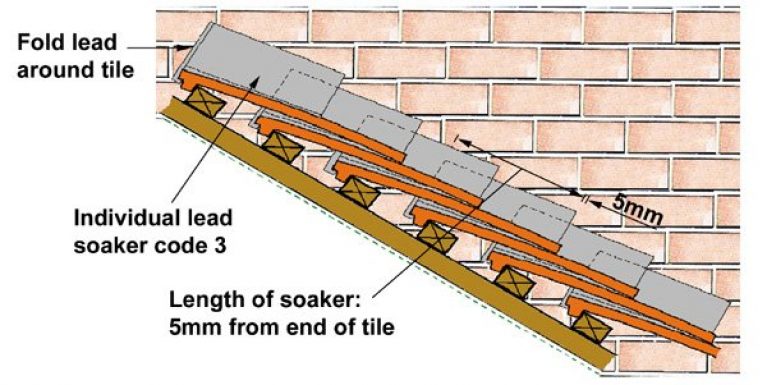

Lead soakers come in a range of different codes, which is how they class the different thicknesses and therefore the purpose of the lead. Soakers installed within roofs are typically made from code 3 lead sheets which are 1.3mm thick (although code 4 lead sheets can be used which are 1.8mm thick). The reason why thin lead soakers are used is that any thicker sheets may affect how they fit beneath the tiles and the overall structure of the roof.

There are many modern alternatives to lead soakers which have been designed to be a cheaper alternative to using lead. However, the lifespan of these products isn’t as long and there is no resell value. Although this sounds negative, the lack of resell value makes it less attractive to thieves. Lead being taken from roofing is a lot less common now, nonetheless the fact there is still value in the used lead which means there will always be a market.

These lead soaker alternatives include products manufactured from materials such as zinc, polypropylene and GRP (all of these are used as common alternatives to lead).

Shape and Fixings

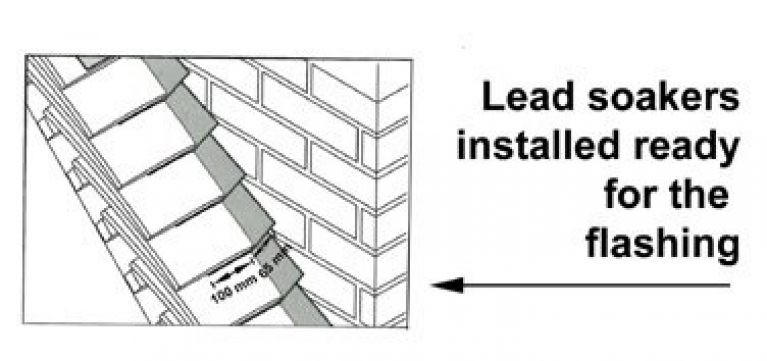

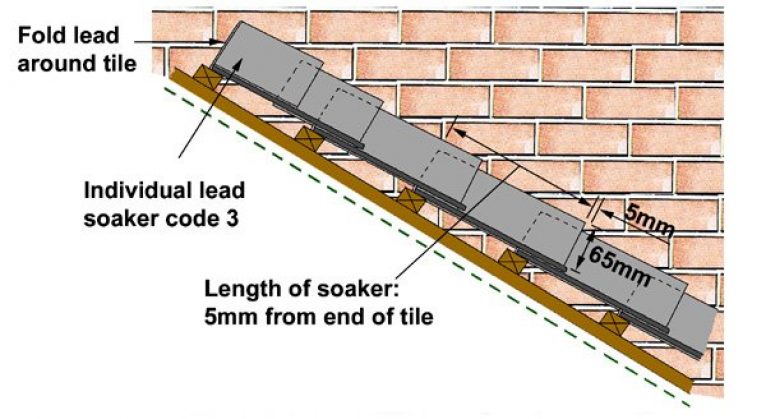

The most traditional shape of lead soakers and flashing is an ‘L shape’, with the bottom side slid under the tile and the other side placed against the structure protruding through the roof. The easiest way to imagine this is lead soakers on a roof surrounding a chimney, with the vertical side of the soaker pressed up against the side of the bottom of the chimney brickwork.

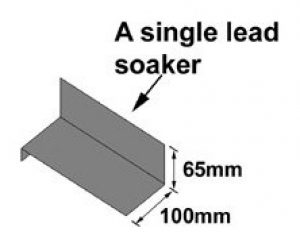

Soakers are typically fixed in position by being nailed into the roofs structure (beneath tiles and then being turned down at the top edge at right angles. To be secured in place and to ensure complete weatherproofing you will need approximately 25mm of excess lead soaker which hooks over the top of the tile. At Wonkee Donkee, we also recommend that you use 100mm worth of lead soaker beneath the tile, parallel to the roof, and a minimum of 65mm of vertical soaker surrounding the protruding feature.

When fitting lead soakers it is vital that you begin at the lowest point of the roof and work upwards with each added soaker overlapping the previous one. This will ensure that any water running down the roof will not seep into gaps and will continue down into the roof’s guttering system.