What is a Brick Wall Tie?

If you have never tried to build or repair a brick wall before you may find yourself asking ‘what is a wall tie?’, and you would be surprised to find out how commonly they are used. The purpose of a wall tie (also commonly referred to as a brick tie) is to join two different walls in cavity buildings together, so that they act as one. Brick wall ties are very visible during the construction process and if you find yourself on any building sites where a cavity wall is being erected and is not yet finished, they will be easy to spot. They are extremely important in providing stability to buildings with cavity walls and are hidden within the wall upon completion.

Why is it important to use wall ties in cavity walls?

As we previously mentioned, brick wall ties provide stability to structures that use cavity walls. When building a cavity wall, you build two different walls and these are referred to in the construction industry as leaves. The inner wall is called the internal leaf and the outer wall is called the outer leaf. Wall ties ensure that these walls are connected and act together as a homogenous unit.

If you don’t install wall ties properly within cavity walls this can lead to long term structural issues. Some examples of what issues can occur when wall ties are not installed correctly include masonry cracks, penetration of damp and in severe cases the outer leaf wall collapsing. Wall ties are now manufactured in order to be resistant from corrosion, be fire resistant and also provide moisture blocks like drip formations which prevents water from penetrating to the inner leaf wall.

What are wall ties made from?

It is believed that cavity walls became most commonly used in the early 1900’s and by the 1920’s cavity walls were used in the construction of most buildings. Over time, the shape and the materials used to manufacture wall ties have changed and innovated many times as you would expect. Some examples of the earliest materials used include plastic and different galvanised steels. As galvanised steels became more popular and their quality increased it was believed that wall ties created with galvanised steel would last the lifetime of each building. Unfortunately, due to losing their corrosive resistance and over time, the mild galvanised steel wall ties began to corrode and weaken as soon as 15-20 years after construction.

As with all technology, especially within the construction industry, wall ties are now predominantly manufactured using stainless steel. The reasoning behind this is that stainless steel already has many protective elements, these include being able to withstand corrosion from commonly encountered elements such as water and cement. The key advantage to this is that the stainless steel does not require an extra layer of protection, so is cheaper to manufacture whilst also providing a maintenance free lifespan.

Although most brick ties on the market are made from mild stainless steel, there are still some other brick ties available on the market. One of the most commonly sold wall ties use composite materials and these help to create a thermal bridging between the walls. You will find these wall ties are the wall ties of choice in construction projects which aim to be ecological and low on energy consumption.

How to install wall ties?

The way in which brick wall ties are installed is obviously dependent on the dimensions and type of wall that you are constructing. For the purpose of this article, we are providing an insight into how to install brick wall ties in standard brick to block construction of cavity walls. As we mentioned previously, wall ties are built into the ‘leaves’ when constructing the walls to provide a coherent structure. A key rule when installing wall ties is to never install into a pre-built joint. Wall ties should always be pressed down with force and surrounded by fresh mortar in order to be effective in tying the walls (leaves) together. In order to prevent moisture from outside entering the wall cavity or reaching the inner leaf, there should be a slight fall from the inner leaf down to the outer leaf. This is also true for the drip part of the wall tie, which should always be pointing downward and be central in the cavity opening.

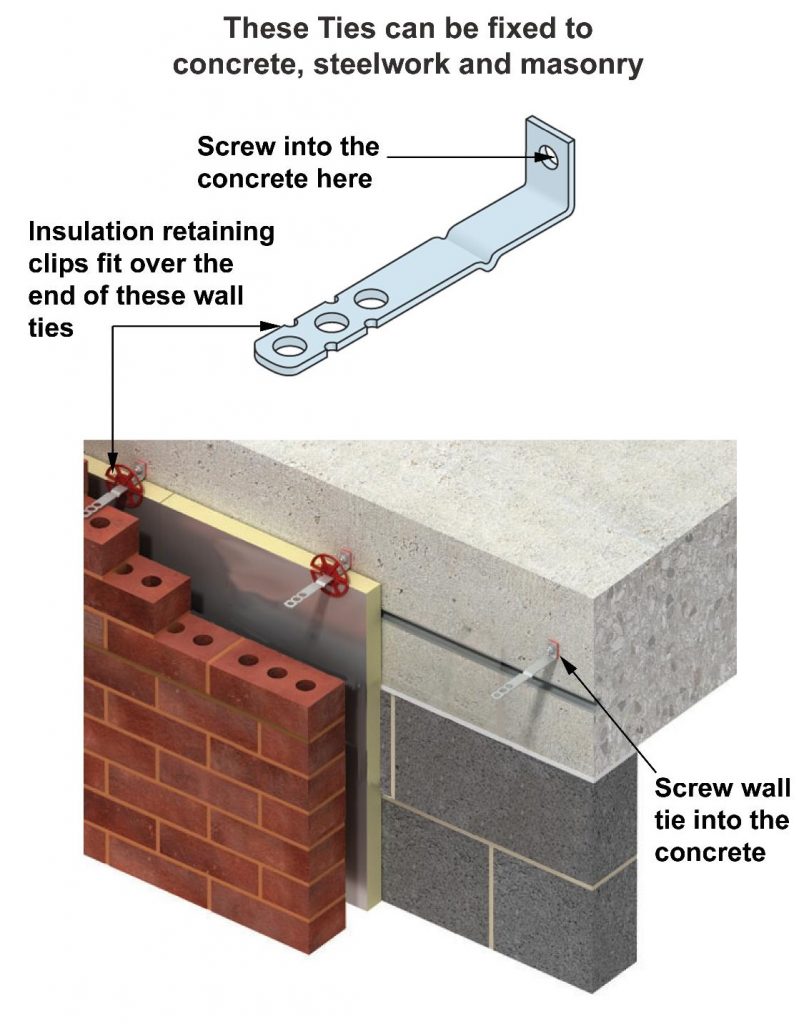

However, not all wall ties are installed in this way as not all construction processes include both the inner leaf and outer leaf wall being constructed at the same time. Examples of construction projects like this include any whereby the inner leaf wall is constructed first and the wall ties are installed during the construction of the external leaf wall.

Where should wall ties be placed?

In order for wall ties to be as effective as possible and provide structure to cavity walls for long periods of time they must be installed at appropriate distances. The most obvious thing to consider when buying wall ties is to ensure that they have the length in order to span the whole cavity space with enough excess wall tie to cover the minimum embedment of the mortar on both wall sides. To provide an example, a 200mm long wall tie is the most appropriate for walls with cavity spaces from 50-75mm.

Obviously, not all walls fit these measurements and walls with bigger cavities (very common in walls that include insulation) will require longer wall ties to account for the extra cavity space. Due to these requirements, you can typically buy wall ties ranging from 50mm to 450mm in length from local hardware and building merchants.

As you would expect, there is red tape and regulations surrounding the installation of wall ties within cavity walls. The Eurocode 6 states that there should be 2.5 wall ties per square metre of wall. In most construction projects you will install wall ties in the same positions, at the same distances apart. Most construction workers typically installed at 900mm horizontal x 450mm vertical spacing. These will tend to be staggered across the cavity wall area to provide an even distribution and a more solid structure to the wall.

You can also include additional wall ties to help reinforce the wall or for walls with features such as openings or unbonded edges. Our recommendation is to have an additional brick tie at a rate of one extra wall tie for approximately every 300mm of height – although we do understand that due to the coursing of blockwork it may be easier to install at around 225mm.

Which wall ties should be selected?

Choosing which is the best wall ties for the cavity wall you are constructing is dependent on a range of different factors. For example, you will need to consider which construction materials you are using for your walls such as the type of masonry, the width of your wall cavity, the dimensions and height of the wall and the geographical location of the project you are undertaking.

As with the majority of construction projects you will have to adhere to a range of building regulations. In this case, the relevant building regulations are the Building Regulations and Eurocodes which can easily be found online. In some locations, there are also more regulations such as the Published Document (PD 6697:2010) which also requires compliance in UK construction projects.

Our advice for choosing the right wall brick ties for your construction project is to first look at all of the relevant wall tie building regulations for your location and then the construction materials you are using.