What are the different types of wood turning chisel?

There are many different types of woodturning chisel. Although they are often called “chisels” there are several different sub-groups:

Gouges

Chisels

Parting Tools

Scrapers

Below is a guide to some of the most commonly used tools.

Gouges

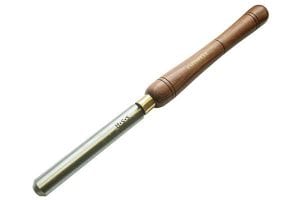

Roughing Gouge

A roughing gouge has a wide fluted blade used to initially round-off a square wooden spindle and to remove most of the excess material. Roughing gouges are for rapid wood removal from spindles and should never be used for bowls.

The rouging gouge’s wide U-shaped cutting edge allows it to remove large amounts of wood very quickly. The bevel of its cutting edge is typically ground to between 40 and 45 degrees.

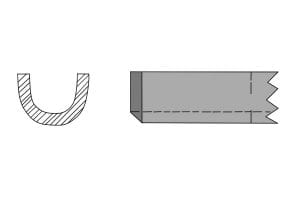

Spindle Gouge

A spindle gouge is essentially a smaller roughing gouge and is used to remove excess material from your workpiece and to create curves (swells and hollows). A spindle gouge would be used in typically smaller, tighter areas than would be practical for a roughing gouge, or to shape a spindle before more intricate details are added.

Note that the spindle gouge’s flute is similar to the roughing gouge’s with the exception that it is shallower. Its cutting edge can be ground to an angle anywhere between 30 and 40 degrees. Many woodturners now grind the cutting edge to what is known as a “fingernail” shape as this makes the tool more versatile.

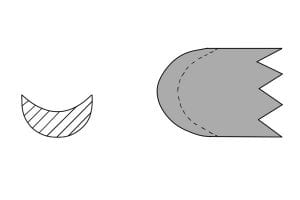

Bowl Gouge

Bowl gouges are used in faceplate turning to hollow out bowls, platters, cups and various other hollow forms. They have a milled flute similar to a spindle gouge, but they are typically much thinner.

A bowl gouge’s blade is very strong (typically milled from high-speed steel). The bowl gouge’s blade needs to be very strong as much of it is often overhanging the tool rest when cutting into the hollow of a bowl.

Chisels

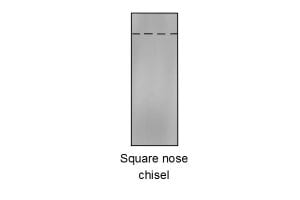

Square Nosed Chisel

A square nose turning chisel is longer than a standard chisel and usually has only one bevel compared to a skew chisel’s two. It has a flat cutting edge that is square to the sides of the blade.

The single bevel of the square nose chisel’s cutting edge is usually ground to between 40 and 60 degrees.

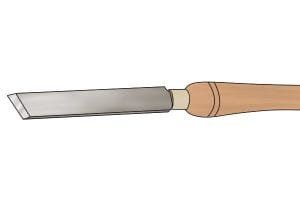

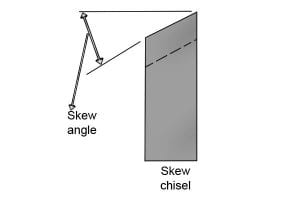

Skew Chisel

A skew chisel has a flat cutting edge that is skewed to one side. It is a very versatile tool that can be used with its blade lying down flat on the workpiece to plane (smooth over) rough areas, or it can be used resting on the thin edge of its blade to cut across the workpiece and to make V-grooves.

The angle of a skew chisel’s cutting edge is typically 45 degrees. The bevels of its cutting edge are usually ground to somewhere between 25 and 55 degrees (12.5 and 27.5 degrees on each side).

Parting Tools

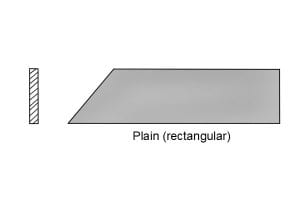

Plain (Rectangular)

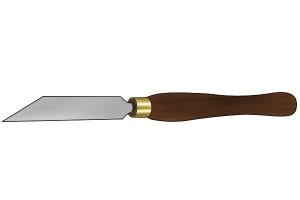

The plain/rectangular parting tool (sometimes called a “knife parting tool”) is used in spindle turning to make thin cuts across your workpiece.

The plain parting tool’s blade is typically shorter than other parting tools and has a rectangular cross-section. The blade is positioned with its narrow edge on the tool rest.

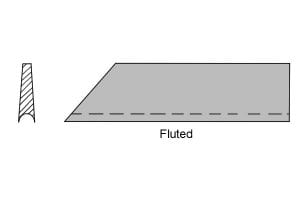

Fluted

A fluted parting tool has a very distinctly shaped cutting edge and is used to impart beads – outwardly rounded shapes – and to cut partings into your workpiece.

The blade is similar in shape to the plain parting tool, with the exception that it has a groove that runs the entire length of the blade which is used to make beads. These fluted blades come in a wide range of thicknesses allowing you to impart beads of various sizes.

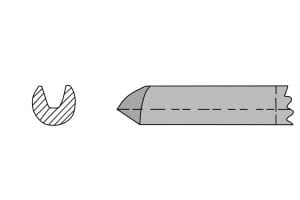

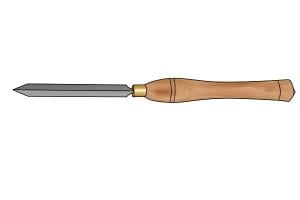

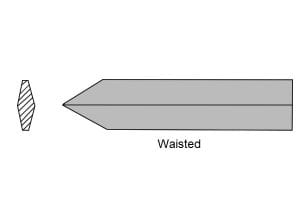

Waisted / Diamond

A waisted (or diamond) parting tool has a bevelled blade with a pointed tip. It is held with its narrow edge resting on the tool rest and is used to cut across a workpiece and to create partings. The tools’ waisted (diamond) cross-section reduces friction between the sides of the tool and the parting cut.

This works because even though the cutting edge gets full contact with the workpiece, the bevelled (sloping) sides of the blade are only in minimal contact at their widest (middle) points.

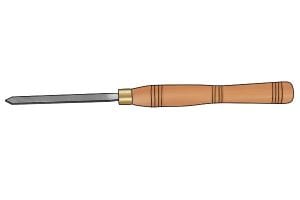

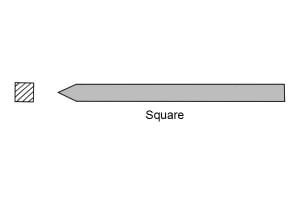

Square

The square parting tool is used for beading work and to cut shallow partings across your workpiece. This tool is only for use with spindle turning.

The blade of a square parting tool is broader than other parting tools and has a sturdy square cross-section. Its cutting edge is double-bevelled and typically ground to between 45 and 50 degrees.

Scrapers

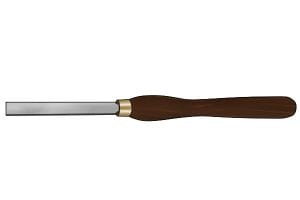

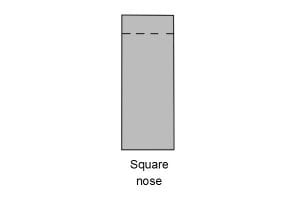

Square Nose

Scrapers are chiefly used in woodturning to create a final smooth finish to a bowl, cup or otherwise hollow form. The square nose scraper is frequently used to smooth the outside of a workpiece. The square nose scraper is positioned with its wide flat edge on the tool rest.

The square nose scraper’s blade has a cutting edge which is square to its edges, and a single bevel, typically at 60-65 degrees. Its blade has a thick, heavy cross-section. Only the very tip of a scraper is used as it is for scraping away small amounts of wood rather than cutting channels or grooves.

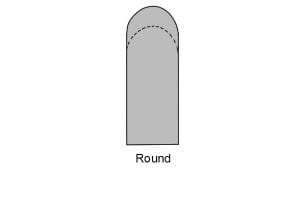

Round Nose

Round nose scrapers are used to shear and smooth the surface of a workpiece. They are frequently used in faceplate turning to smooth the inside surfaces of bowls and cups. They may also be used in spindle turning for smoothing coves.

A top quality round nose scraper has a thick blade with a heavy rectangular cross-section. Its rounded cutting edge typically has a single bevel of between 60 and 65 degrees.

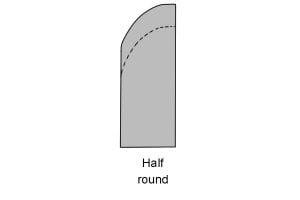

Half Round

A half-round scraper is used for smoothing surfaces, frequently the internal portion of a bowl or other hollow form.

As the name suggests, the half-round scraper’s blade has one flat side and one curved side. Like many scrapers, the blade is typically thick with a heavy rectangular cross-section and a single ground bevel of between 60 and 65 degrees.