What is stainless steel? |

||||

|

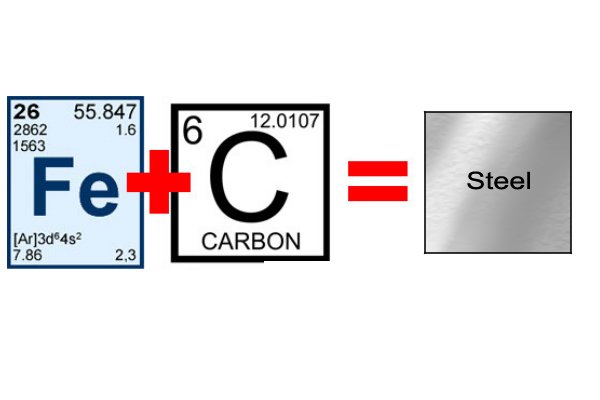

Steels are a family of alloys based on iron and carbon. Stainless steels also contains chromium, and are a subgroup of steels, rather than a single material.

Standard steel rusts easily in moisture, and stains if exposed to acids, so stainless steel was developed to stain ‘less’ and resist rust and corrosion. |

|||

|

||||

|

There are currently over 150 different grades of stainless steel, with about 15 being the most commonly used. Austenitic stainless steels are the most widely used, with 304 and 316 stainless steels being two of the most popular grades. |

|||

Composition of stainless steel |

||||

|

The addition of chromium to a low carbon steel changes its properties. Usually a minimum of 10.5% chromium needs to be present for steel to be classed as stainless, with the cutlery industry using a standard of 13%. Also, there needs to be less than 1.2% carbon present. |

|||

|

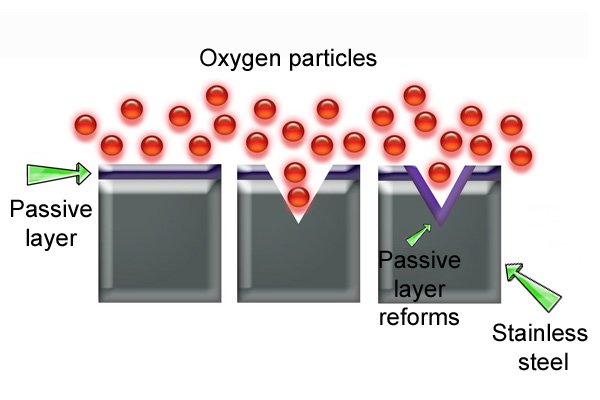

This composition is necessary for stainless steel to be able to build up a ‘self-healing’ layer on its surface, called the ‘passive’ layer. A material is classed as ‘passive’ when it is less affected by environmental factors. This passive layer is chrome oxide, and it protects the steel beneath it. If stainless steel is scratched, the passive layer can reform, as long as it has exposure to oxygen. |

|||

|

The properties of stainless steel can be altered by the addition of other elements. Even trace amounts of some elements drastically alter the alloy’s corrosion resistance.

Elements which can be added to stainless steels include vanadium, nickel, niobium, or molybdenum. The most corrosion resistant and usually most expensive, usually have high amounts of chromium, molybdenum and nickel. |

|||

A brief history of stainless steel |

||||

|

Some rust-resistant alloys have been found which date back to ancient times. A famous example is the Iron pillar from Delhi, dating back to around the 4th/5th Century AD. This 7.3-metre tall pillar was forged out of wrought iron, yet it’s resisted corrosion for about 1,600 years. Although no chromium is present in the iron, it’s believed its corrosion resistance is due to higher levels of phosphorus. It wasn’t until around 1820 that scientists noted that irons alloyed with chromium were more resistant to corrosion from certain acids. Then, in 1875, a crucial development was made in France, when the importance of the low carbon content was detailed. |

|||

|

Arguably, the first stainless steel was actually created accidentally, by Harry Brearley of Sheffield, in 1913. Brearley was trying to find erosion-resistant steel for making gun barrels. He discovered a steel with 12.8% chromium and 0.24% carbon resisted corrosion from acids and went on to produce the first cutlery in this stainless material. Although other scientists in different countries were also making similar discoveries around this time, Brearley was the first to use the name ‘stainless’, which has stuck ever since. |

|||

What are the different types of stainless steel? |

||||

|

Adding different elements to stainless steel, as well as the chromium, change its microstructure. The microstructure of stainless steels are used to group them into families and each grade is developed within these families.

These are the main groups: |

|||

|

Austenitic stainless steelsThese are the most commonly used, making up about 70% of the world’s stainless steel usage. They are generally suited to use in low temperatures, including cryogenic applications, unlike many other steels which become brittle at reduced temperatures. |

|||

|

||||

|

They can be work hardened with cold working and are the easiest stainless steels to form, although they can’t be hardened with heat treatment. Elements, such as molybdenum, can be added to increase the corrosion resistance and make them suitable for use in high-temperature applications. |

|||

|

Ferritic stainless steelsThese stainless steels contain little or no nickel, consisting mainly of iron and chromium. They have the advantage of being corrosion-resistant at high temperatures, but generally less resistant to corrosion than austenitic steels, and less ductile. They can’t be hardened with heat treatment and are magnetic. |

|||

|

Martensitic stainless steelsThese contain higher levels of carbon than other stainless steels, which means that they can be hardened with heat treatment, like alloy steels. However, they can’t be cold worked and have poor weldability. They maintain moderate corrosion resistance and are magnetic. |

|||

|

Duplex stainless steelsThese steels have two microstructure phases, austenite and ferrite, and combine the properties of both those stainless steel families. They are stronger than ferritic and austenitic steels and also more resistant to chloride corrosion. These are usually found in industrial applications such as chemical plants and offshore gas and oil installations. |

|||

What are the properties of stainless steel? |

||||

|

Stainless steels are particularly versatile, and can maintain the strength of standard steel, with the added advantage of corrosion and oxidation resistance. |

|||

|

ADVANTAGES |

|

DISADVANTAGES |

|||||

|

|

|||||||

Uses of stainless steel |

||||

|

Stainless steels are used extensively, in many applications and for many different industries. Here are just a few common uses for them: |

|||

|

DIY industryMany tools are made from stainless steel, and it’s a fairly popular choice due to its strength, durability and resistance to corrosion. As a result, stainless steel tools may be more expensive than some standard steel tools.

Note: Stainless steel may not be as strong as some steel, especially if it has been hardened through heat treatment. |

|||

|

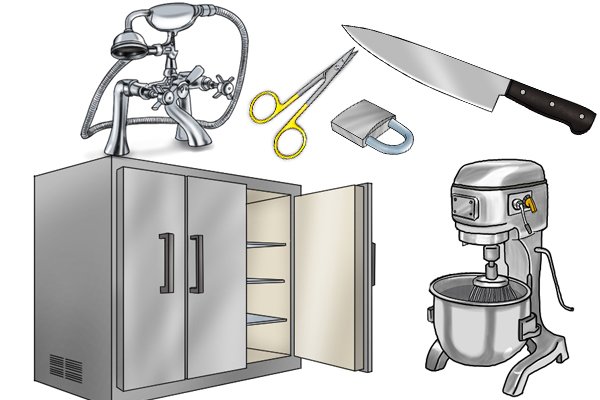

Examples of tools which are often made of stainless steels include blades of various cutting tools such as knives or shears, pliers, scrapers, multi-tools, and many measuring instruments, such as gauges, callipers, or rulers.

You will often find that stainless steel is used for tools that will be continually subjected to moisture throughout their working life, either from the materials they come into contact with or as a result of being used outdoors or in humid conditions, where corrosion is a potential risk. |

|||

|

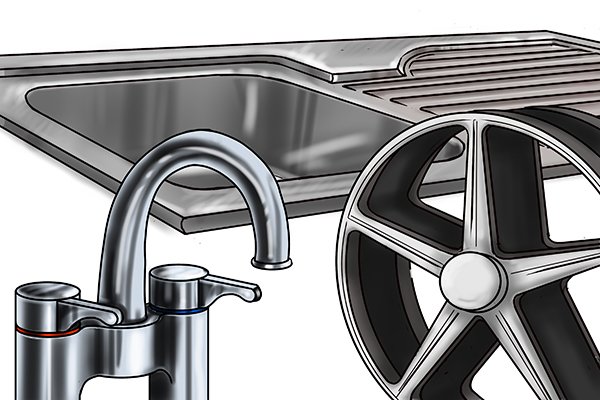

DomesticYou will find stainless steel items in many places around the home. Such items include jewellery, cutlery, knives, cookware, sinks, appliances such as cookers, freezers, and washing machine drums, as well as things like knives and razor blades. |

|||

|

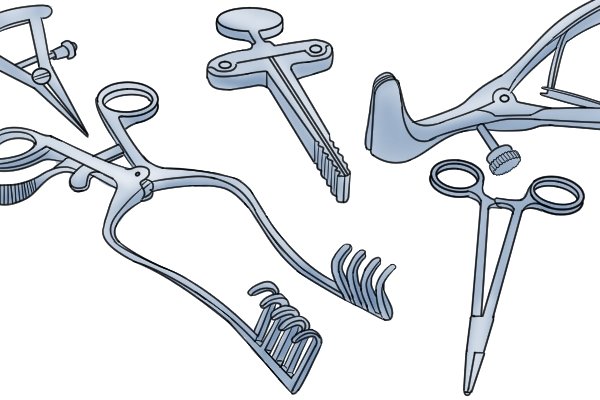

Medical and surgical equipmentStainless steels are hygienic, can be easily serialised, and won’t corrode, so they are popular materials for medical and surgical equipment.

Stainless steel is used for making a huge range of medical instruments and also operating tables and some surgical implants. |

|||

|

TransportStainless steels are used across a range of different transport vehicles. This includes exhausts and trims on cars, tankers, aircrafts, road tankers, ship containers and tankers, refuse vehicles and rail carriers. |

|||

|

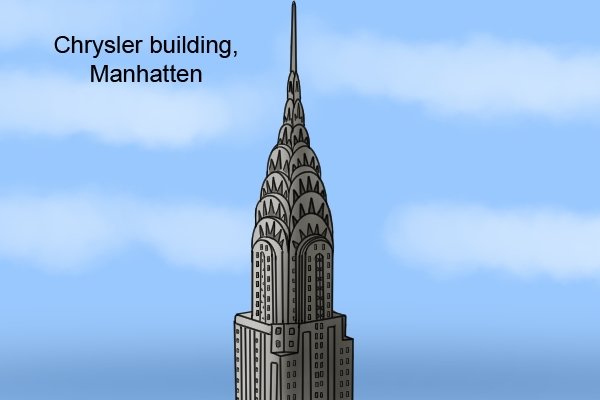

Architecture and constructionStainless steels have been commonly used in construction for decades, for things such as door and window fittings, cladding, handrails, structural sections, and reinforcement bars. They are now also used on a larger scale, particularly with high impact buildings. |

|||

|

Some famous stainless steel structures include the Gateway Arch in St. Louis, the top of the Chrysler building, the Eurostar tunnel in London, the Petronas towers in Kuala Lumpur, the Cala Galdana Bridge in Spain, and the Walt Disney concert hall, by Frank Gehry, in Los Angeles. |

|||